Increase efficiency in glass manufacturing and other industrial processes through digitalization.

Digital transformation is shifting industries around the world, from automotive and aerospace to energy and manufacturing. Traditional workflows are integrating digital tools to accelerate production, advance design, cut costs, and reduce material waste — the last of which connects with another marked trend: sustainability. In fact, in many instances, digital transformation and sustainability go hand in hand. By incorporating new technologies that enable virtual monitoring, testing, and prototyping, organizations improve internal operations and maintenance (O&M) while producing cleaner products. This is happening across the manufacturing industry, including the glass manufacturing sector.

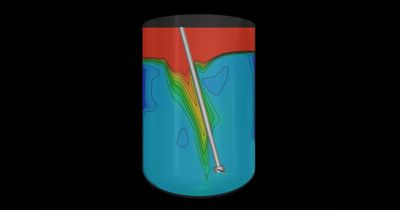

Still, adopting digital workflows while targeting sustainability goals and adhering to environmental standards — notable carbon-reduction initiatives aim to halve emissions by 2030 and reach net-zero by 2050 — can present challenges in some industries. For example, sensor technology enables teams to better monitor their assets and optimize O&M, but many industrial processes, such as glass manufacturing, involve extreme temperatures and environments, often making physical sensors impractical or even impossible.

Digital twins — virtual representations of real-world entities and processes, synchronized at a specified frequency and fidelity — enable teams to leverage simulation to monitor assets without relying on physical sensors alone. Taking it one step further, hybrid digital twins blend data and physics to create an even more accurate representation of operating behavior through these virtual sensors. Let’s explore how Ansys’ hybrid digital twin solutions help glass manufacturing and other industrial operations embrace digital transformation, optimize workflows, and meet sustainability goals.

Understanding the Challenges in Glass Manufacturing

Top challenges in glass manufacturing include sustainability, quality, and increased productivity. This is known as “the glass trifecta,” according to Hossam Metwally, a senior principal application engineer at Ansys.

Although glass has a positive reputation for its recyclability and usefulness in sustainable building design, its manufacturing process is not as eco-friendly.

“It’s actually an extremely energy-intensive process, which can potentially have a negative impact in terms of energy consumption and carbon footprint,” Metwally said during an episode of The Twin Talks, an Ansys interview series dedicated to digital twin technology. “And because of that, people are looking into new technologies to reduce this environmental impact and potentially new technologies also for newer glass manufacturing processes.”

This represents the sustainability portion of the trifecta, but the other two challenges — quality and increased productivity — are closely tied to energy consumption too.

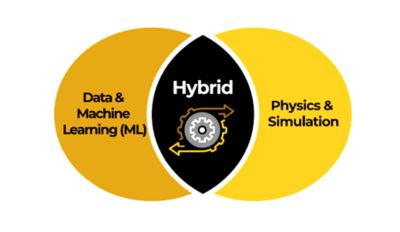

Hybrid digital twins blend data and physics to create the best possible representation of actual operating behavior.

Get To Know Hybrid Digital Twins

Hybrid digital twins expand the value of digital twins by blending data and physics. In other words, hybrid digital twins offer the best of both worlds, including critical insights from field observation data and physics-based simulation.

As a result, hybrid digital twins enable real-time monitoring, predictive maintenance, and performance optimization across operating scenarios and product variations, automatically adapting to changing environments, circumstances, and conditions.

Through artificial intelligence/machine learning (AI/ML) integration, you can create hybrid digital twins with the Ansys Twin Builder simulation-based digital twin platform and Ansys TwinAI AI-powered digital twin software.

As demands increase for newer, more high-tech glass applications, the need for higher-quality glass increases, which requires more energy to manufacture and produce. Similarly, in terms of increased productivity, or what Metwally refers to as agile productivity, glass manufacturers are being challenged to produce glass at a faster rate while adhering to ever-changing specifications. Again, this level of agility requires advanced processing and more energy.

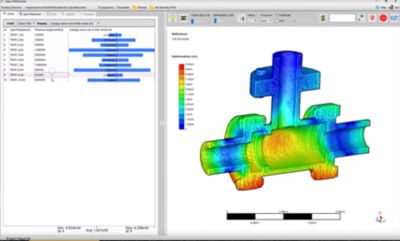

Ansys’ hybrid digital twin solutions enable reduced-order modeling (ROM), which simplifies computationally heavy models.

Overcome Manufacturing Hurdles With Simulation

Glass manufacturers have incorporated multiphysics simulation solutions, including computational fluid dynamics (CFD), for applications like combustion modeling and heat assessment and to predict glass temperature in different parts of the system. Today, Ansys’ hybrid digital twin solutions offer additional assistance, enabling manufacturers to blend data and physics to monitor the entire production process from start to finish. By integrating field behavior data with physics-based simulation, virtual sensors enable manufacturers to monitor and predict issues before they happen, which reduces energy consumption and serves as a more viable solution in extreme temperatures or environments. In connection, predictive maintenance minimizes equipment downtime and degradation — another energy saver.

Hybrid digital twins also enable engineers to incorporate high-fidelity design models into operations through techniques like reduced-order modeling (ROM), which simplifies complex and computationally heavy models into lightweight, faster-running models without sacrificing accuracy or fidelity. This democratizes simulation by delivering simulation insights that were previously hard to understand by simulation novices to team members across units, including plant operators on the manufacturing floor. In addition, high-fidelity system models and hybrid digital twins create new possibilities for the virtual commissioning of plants and virtual training of new operators.

Further, Ansys’ hybrid digital twin solutions enable operational telemetry, also known as real-time monitoring, which informs and integrates with artificial intelligence/machine learning (AI/ML) algorithms to bring adaptation to an asset’s reality. This is how hybrid digital twins can adapt and update automatically to shifting conditions.

Embrace Increasing Digital Transformation

Simulation experts are noticing an increase in digital transformation in the glass manufacturing industry. Joining Metwally to discuss the topic, Jose Luis Gonzalez Hernandez, a senior application engineer at Ansys, credited a few driving factors during the episode, including the glass trifecta of challenges, digitalization, and a desired faster time to market. He added that digital twin technology provides a comprehensive solution.

“By using our Ansys digital twins, customers in the glass industry are unlocking additional value,” he said. “This translates to more efficient processes, reduced time to market, (and) also reduced maintenance cost and higher-quality products.”

Although Metwally’s trifecta term describes challenges specific to the glass industry, digital twin technology is being used to combat similar challenges during other manufacturing processes.

For example, Tata Steel Nederland, one of Europe’s leading steelmakers, integrates Ansys’ digital twin solutions to increase energy efficiency and reach decarbonization goals by digitalizing thermal process management at their plants.

In addition, studies reveal an increase in digital twin use across the industrial field. A 2022 McKinsey & Co. survey found that 86% of polled industrial executives believed a digital twin was applicable to their production operations and 44% had already implemented one.

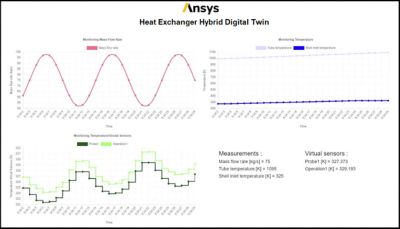

Hybrid digital twins enable you to monitor industrial equipment using virtual sensors and merge data from field behavior data with insights from physics-based simulation.

“Traditional monitoring of assets and process with data alone is not always enough to make a step-change improvement to some of the issues that the energy sector is facing,” said Mark Bate, a product sales executive at Ansys, during a sustainability-focused episode of The Twin Talks. “But what we are seeing is those companies that are adopting a sort of joint approach with data and physics together to create hybrid digital twins are making the quickest and most significant improvements.”

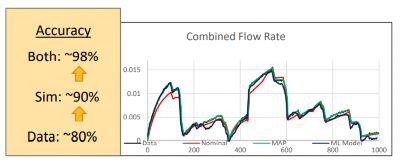

The graph illustrates the accuracy flow rate of combining data-driven modeling with simulation-based modeling.

An Ansys paper published in IEEE Software found that data-driven models provide roughly 80% accuracy while simulation-based models deliver about 90% accuracy. The journal reported that combining these methods produces about 98% accuracy.

Bate said the combination supports industrial sustainability initiatives.

“Especially in thermally intensive industries like power, oil and gas, blast rubber, steel, and so on — most of these (industries) will already have some kind of sustainability program as the key business initiative to reduce carbon emissions and also have plans to continuously improve asset and operational efficiency,” he said. “Using physics simulation and data, you can create hybrid digital twins to predict things and measure things that you’re not able to do now. So, you can make significant improvements on how you operate and maintain your assets above and beyond what is capable today.”

Ansys simulation and hybrid digital twin solutions support predictive maintenance through virtual sensors. This reduces energy consumption during common manufacturing processes and helps in extreme temperatures and environments.

Discover Hybrid Digital Twins

To learn more about hybrid digital twins and Ansys’ latest digital twin solution, Ansys TwinAI AI-powered digital twin software, register for the on-demand webinar “Ansys TwinAI: Combining Physics Accuracy With Data-Driven Insights” or explore the software firsthand with a free trial.