-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

Ansys has introduced the Ansys TwinAI digital twin solution that seamlessly integrates the accuracy of physics models with insights from real-world data, powered by cutting-edge artificial intelligence and machine learning (AI/ML) techniques. TwinAI software delivers unmatched precision and speed while unleashing the full potential of digital twins.

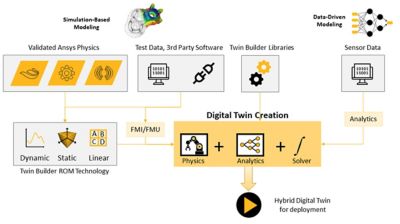

This addition to the Ansys Digital Twin offering allows the creation, validation, and deployment of a digital twin model in an environment that is closer to what can be found in cloud infrastructures, with respect to simulation engine and operating system data streams. It benefits you in three ways:

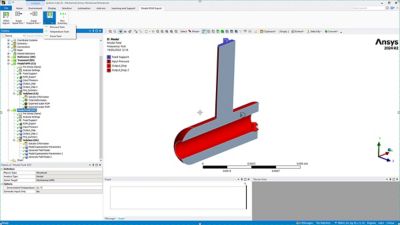

- Creating digital twins with reduced-order models (ROMs) or functional mock-up units (FMUs), possibly extended with Python code.

- Enhancing the accuracy of twins with hybrid analytics — for example, calibrating existing twins with new data coming from the field or filling the gap between prediction and measurement using ML-based models.

- Simplifying and streamlining the process for cloud and/or edge deployment.

Reduced-order models (ROMs) are simplifications of complex models that capture the behavior of source models so engineers and designers can quickly study a system’s dominant effects using minimal computational resources.

Challenges in Digital Twin Deployment

When deploying digital twins, a few challenges are commonly encountered.

First, digital twin creation and validation, which consist of creating a sufficiently accurate representation of the asset and effects that we want to track with the twin, typically happen in a modeling environment that is not necessarily consistent with the environment used for deploying and executing the twin. These differences might come from multiple aspects, such as different mechanisms to feed the input data used by the twin, different solvers used to simulate the models, or different operating systems. TwinAI software provides you with a graphical environment to import the generated twin, cross-compile the models when required to execute on different operating systems, and test and validate twin simulation to ensure that its execution performance and accuracy are as expected before deploying.

Creating a performant, accurate twin model is one step, but deploying a digital twin requires additional considerations. In particular, how can the twin execution be integrated in a larger deployment workflow connected to other applications — for example, to pass the acquired data from the connected assets to the twin, to collect prediction from the twin in the form of time series and/or 2D and 3D field data visualization, and to use these predictions to derive key performance indicators that are relevant to the consumers of the twin? For those aspects, TwinAI software has capabilities to package twin models in the form of portable, scalable runtime applications, with direct application programming interfaces (APIs) available to manipulate and execute the twins. It also makes it possible to generate scaffolding deployment application code, which the user can directly use and extend to integrate the twins in the deployment environment.

One of our Ansys PyAnsys packages, the Ansys PyTwin offering, provides access to a Python version of these APIs that you can integrate with any Python-based workflow. Beyond Python and web application scaffolding code, there are options to deliver a containerized version of the twin application, coming with a set of REST APIs exposed, which typically is better suited for cloud and Internet-of-Things applications integration. The container has the advantage of packaging not only the twin application but all the dependencies required to properly integrate and execute it so it can be deployed easily at scale in the cloud.

How To Successfully Deploy Your Digital Twins

Several examples can be used to illustrate digital twin deployments and their benefits. For instance, we have been working with a leading flow equipment manufacturer, who wanted to provide a monitoring solution to their customer, a public utility. However, diagnostic sensors could not be added due to cost and feasibility. Using Ansys products and hybrid digital twins, the equipment manufacturer has built physics-accurate representations of the utility’s flow networks, with prediction by virtual sensors as accurate as actual flow rates.

Hybrid digital twin solution architecture

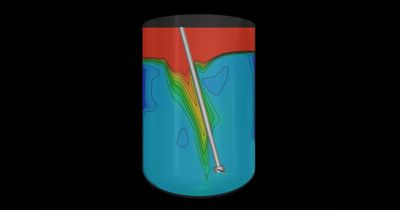

Another example can be found in heavy energy industries like steel or glass manufacturing, in which installation of physical sensors generally is not feasible due to high temperatures and harsh conditions. Being able to create digital twins from physics-based models and ROMs enables you to get accurate, fast predictions of various quantities, which helps control manufacturing processes and maximize production quality. (See “Simulation Takes the Heat off Tata Steel During Production” and “How Digital Twin Is a Game Changer for Tata Steel Nederland to Achieve Their Targets.”)

A torpedo ladle car being transported from the blast furnaces, which are visible in the background, to the steel plant. Image courtesy of Tata Steel.

“Innovation fuels progress, and at Tata Steel Nederland we’re pioneering a transformative journey toward sustainability. By harnessing the power of simulation and AI, we’re optimizing our production processes, minimizing energy loss, and driving toward our decarbonization goals. Ansys TwinAI software seamlessly combines simulation and data with AI to revolutionize steel manufacturing for a cleaner, greener future. With CO2 reduction targets of 30% to 40% by 2030 and being carbon-neutral by 2045, Ansys TwinAI software is instrumental in leveraging Tata Steel Nederland’s energy efficiency and achieving our decarbonization goals.”

— Paul van Beurden, knowledge group leader of research and development at Tata Steel Nederland

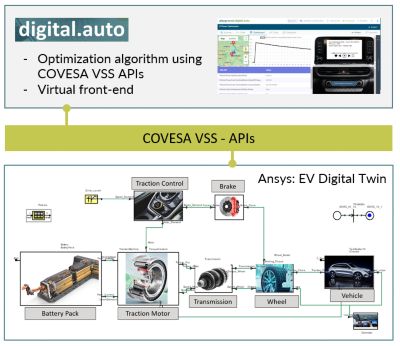

Finally, we have had the opportunity to collaborate with global automotive suppliers to demonstrate the possibility of deploying detailed, simulation-based digital twin models of electric vehicle systems so their ranges can be accurately predicted based on user-selected comfort-level policies. (See “Understanding the Calculus Behind EV Range: How Far Is Far Enough?”)

Shown is Ansys electric vehicle (EV) digital twin integration with COVESA vehicle signal specification and digital.auto. The digital.auto platform hosting the COVESA application programming interfaces (APIs) appears on the front end while the Ansys EV digital twin operates on the back end.

TwinAI software capabilities are key for all these different use cases to help create digital twin models and extend them with hybrid analytics capabilities, as well as streamlining the deployment process through scaffolding code and container generation.

Facilitating Collaboration for Seamless Deployment

Digital twin creation and deployment activities involve several steps that typically are handled by different people and teams. On one side are the modeling creation and validation steps, which involve application modeling and simulation experts who look at things like model and prediction accuracy, robustness, and execution performance. On the other hand, deployment activities involve people closer to information technology and operations, who are more concerned about APIs and application integration and deployment.

As explained earlier, it is very important to ensure that the models created and validated by the application experts can be reused in a consistent way when deployed in operations. TwinAI software bridges the gap between the sides, helping you to bring their models and digital twins together, and validating the models and twins in an environment that uses the same technologies as the environments used to deploy and execute twins elsewhere. TwinAI software generates self-contained, portable applications that can be integrated with provided APIs.

Future Developments

We are considering multiple areas for future developments and will continue to support your digital twin creation and deployment journey.

One important upcoming benefit is to bring in more and more digital twin creation capabilities from a modeling perspective to streamline the full process of twin creation and execution. As an example, starting with the upcoming 2024 R2 release, we will launch ROM capabilities in TwinAI software so users easily can build and deploy twins based on ROMs using a single environment.

Another important area is to keep adding capabilities related to hybrid digital twins and AI/ML so our physics-based twins can be more accurate with data and be updated when deployed in the field. We also will continue supporting our IoT partners and deployment ecosystem by providing more deployment and API-related capabilities to facilitate integration and overall deployment.

For more information, register for the Ansys TwinAI: Combining Physics Accuracy with Data-Driven Insights webinar.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.