-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

October 26, 2023

Enable Faster Product Design Decisions with SPDM and VCollab

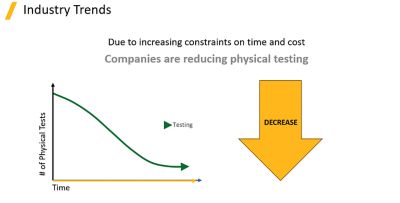

In today’s evolving digital landscape, product development teams are increasingly supporting a trend to “shift simulation to the left,” which means engineers and designers are performing simulation earlier in design and development cycles. By introducing simulation as an active part of development instead of a late-stage verification tool, development teams gain critical insights sooner to inform designs, prevent design failure, save time and costs, and reduce time to market. As a result, simulations have evolved from supplementary tools to critical components in the product development process, offering a virtual means for testing and validating product designs, which, in many cases, significantly reduces physical testing and prototyping.

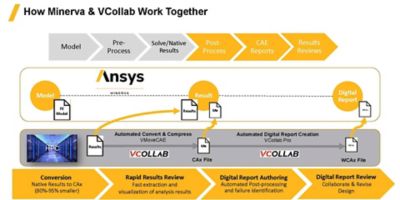

Though advantageous, this transition inundates design and development teams with a growing number of digital tools and greater amount of data. Simulation process and data management (SPDM) software, such as Ansys Minerva, helps companies embrace this digital transformation by enabling teams to manage simulations, data, workflows, and resources from one central database. But that’s not all. Minerva takes SPDM even further through integration with Visual Collaboration Technologies (VCollab) solutions, which automate and accelerate tedious post-processing simulation steps. VCollab’s unique digital capabilities are embedded within Minerva’s robust SPDM platform, creating a paradigm shift in computer-aided engineering (CAE) strategy. Together, Minerva and VCollab democratize simulation, enhance SPDM, and streamline product design with informed insights that accelerate confident decision-making.

Make the Call with Minerva and VCollab

Essentially, companies integrate simulation to gain predictive insights that power faster and smarter engineering decisions. Still, even with simulation, the journey from design challenges to design solutions can be long and overwhelming, with steps such as data collection, analysis, and post-processing. Minerva and VCollab’s joint capabilities streamline SPDM so teams can answer difficult design questions faster and more accurately.

The Minerva–VCollab joint solution enables you to:

- Manage simulation results easier and more efficiently.

- Streamline “analysis to design decision” process.

- Automate time-consuming and repetitive tasks.

- Enhance virtual/visual collaboration.

Ansys Minerva takes simulation process and data management (SPDM) to the next level with embedded digital capabilities from Visual Collaboration Technologies (VCollab), including the swift extraction and visualization of key analysis results across multiple computer-aided engineering (CAE) tools.

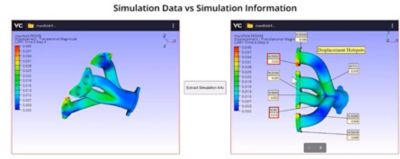

Initially, VCollab acts as a preparatory step, consolidating and refining raw simulation data for more effective SPDM. Ultimately, VCollab digitally transforms the design review process by swiftly extracting metadata and visualizing key analysis results from multiple CAE solutions. It then compiles that into a solver-independent compact file format (.cax) for simulation results management. VCollab’s compact result files (CAx) and digital slides help companies efficiently store, move, and manage simulation results and simulation reports in the digital thread. Together with the smart automation of post-processing and failure identification, VCollab’s digital slide-based reports facilitate a rapid results review process. This eliminates the traditionally tedious manual post-processing and reporting stage, ensuring that companies can make more informed design decisions at an accelerated pace.

In summary, VCollab’s rapid results review capabilities in Minerva enable engineers to accelerate the “analysis to design decision” process by:

- Smart automation and efficient multi-format graphic displays (digital slides), which are essential for design decision meetings.

- Ease of sharing graphical results data with the broader engineering team using its HTML capabilities.

- Dramatic reduction of result file sizes (80-95% smaller on average) once processed through VCollab, enabling the ability to store, retrieve, and archive results for access whenever additional information is needed.

- Automatic generation of digital reports.

Additionally, VCollab’s data analytics capability allows engineers to comb through vast amounts of data from multiple CAE solvers, quickly identifying potential areas of concern within the product or system. Consequently, VCollab technology also alleviates storage concerns by transforming massive native files into compact data sets.

Embedded in Minerva, VCollab digitally transforms the design review process by consolidating and refining raw data for more effective SPDM.

Minerva features capabilities from some of VCollab’s top products including VMoveCAE, VMoveCAD, and VCollabWeb (which uses the file format .wcax). In addition, Minerva can seamlessly integrate with VCollabPRO.

Minerva integrates with top VCollab products that accelerate the design process and enable faster decision-making.

Increase Accessibility with SPDM, VCollab, and the Cloud

Making the workflow even more convenient, the combination of Minerva’s open platform and VCollab technology uniquely delivers vendor-neutral capabilities that support a diverse spectrum of CAE tools, including non-Ansys simulation tools. This means that Minerva can easily manage, interpret, and apply a wider range of simulation analyses, which increases team collaboration, expands data insight, informs smarter design decisions, and ultimately improves design quality.

Expanding upon this, Minerva’s cloud capabilities enable accessibility from anywhere, which encourages even more involvement across organizations both domestically and internationally. Further, VCollab serves as Minerva’s 3D dashboard, facilitating a smoother results review process with digital slides for informed design decision-making and promoting near-real-time visual interactions among global teams. By automating the process of extracting, merging, and reporting multiphysics simulation insights in high-fidelity, browser-viewable 3D models and digital slides, VCollab makes critical simulation insights accessible to everyone involved in the design and manufacturing process. Virtual prototypes are much easier and more feasible to circulate around the team for input than physical prototypes. Design changes are much easier and more affordable to implement in a virtual model rather than a physical prototype.

With configurable, role-based dashboards in Minerva, managers and team members across an organization can retrieve the status of work in progress, key metrics, assignments, and much more — even if a team member is not a simulation expert, in a different department, or located overseas. In this way, the Minerva–VCollab solution democratizes simulation and prevents delays during design and production.

In a growing trend to “shift simulation to the left,” engineers and designers incorporate simulation earlier in design and development to inform designs, prevent design failure, save time and cost, and shorten time to market.

Decide to Design Smarter Today

As technology continues to advance and digitally transform nearly every industry around the world, Minerva and VCollab empower organizations to maximize the value of simulation and handle increasing workloads with ease. Companies can foster innovation and maintain their competitive edge by leveraging SPDM and VCollab technology to streamline simulation analyses and inform smarter and faster design decisions throughout the product creation and launch process.

To learn more about Minerva and how an SPDM solution can benefit your team explore the Ansys Minerva Webinar Series and register for on-demand access today.