As sustainability initiatives to reduce greenhouse gas (GHG) emissions increase worldwide, interest in renewable energy resources continues to grow. However, renewable energy can be costly, limited by region, and unreliable. For these reasons, battery energy storage systems (BESSs) are influential in widespread renewable energy adoption.

Battery storage supports renewable energy by collecting and saving excess electricity produced from renewable sources like solar and wind power. This makes renewable energy accessible even when renewable sources are not producing enough electricity. With such environmental appeal, the global BESS market is expected to exceed $120 billion by 2030, according to McKinsey & Co. The continued universal shift toward electric vehicles (EVs) likely contributes to the expected surge.

Established in 2019, Element Energy recognized a growing need for sustainable battery systems. Since then, the California-based startup has remained dedicated to improving the safety, intelligence, and economics of large-format battery systems and supporting a circular economy for batteries. One of its main focuses is second-life battery (SLB) applications — that is, taking used batteries and redeploying them for extended energy storage.

Along with securing access to Ansys simulation through the Ansys Startup Program, KETIV Technologies, an Ansys Select Channel Partner, provided critical guidance that accelerated Element Energy’s adoption of advanced simulation techniques, enabling iterative design changes to its technology virtually. This minimizes the need for physical prototypes and tests, which can be costly and time-consuming. By integrating Ansys structural, fluids, and electronics simulation, the eco-conscious startup optimizes design, cuts development time in half, and reduces costs while continuing its mission to advance sustainable battery solutions.

Understanding BMS Technology

What sets Element Energy apart from other battery management system (BMS) companies? According to the startup, its battery storage technology is safer, lasts longer, and produces a higher output. If you’re wondering how that’s possible, the company says it comes down to its technology architecture, which is designed using Ansys simulation.

“We actively use Ansys tools to determine our engineering design decisions at various levels of our systems,” says Corrado Cammi, vice president of engineering at Element Energy.

The team began integrating Ansys multiphysics simulation in 2021 and regularly incorporates seven Ansys solutions into its workflow today.

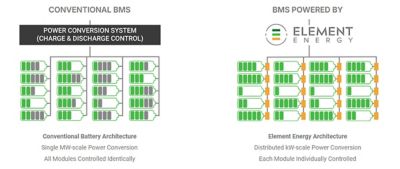

Conventional battery management system (BMS) architecture is static and controlled with a centralized system while Element Energy’s BMS architecture is distributed and adaptive with power conversion dedicated to each individual module.

While conventional BMS architecture is static and controlled with a centralized system, Element Energy’s BMS architecture is distributed and adaptive with power conversion dedicated to each individual module. In other words, in a conventional battery pack, cells are electrically connected in series and monitored through a centralized BMS. So, during a charge or discharge, the same load is applied to each cell despite the actual state of each cell. For example, cells with different states of health, degradation, or safety are still charged or discharged at the same rate.

On the other hand, Element Energy’s architecture combines BMS functions with power control and takes a distributed approach. In this type of system, each cell module, made up of a limited number of cells in series, is controlled by a BMS board that embeds a power conversion stage. This enables each cell to be monitored individually while the module power load is controlled through the power conversion stage. In Element Energy’s BMS, a battery pack comprises several modules in series and the power load or profile can be individually controlled.

Element Energy is dedicated to improving the safety, intelligence, and economics of large-format battery systems and supporting a circular economy for batteries.

In addition, Element Energy’s BMS enables cloud-based monitoring. While not every individual control unit is directly connected to the cloud, data is aggregated by a master controller that communicates to the cloud. And thanks to the architecture described above, Element Energy systems can run diagnostic measurements on one or more modules at a time, continuously and seamlessly, as the overall system keeps operating based on its commercial application. This allows the algorithms running in the cloud to accurately determine each cell’s health, degradation, or safety. The results of this analysis are then sent from the cloud to the local controllers to manage the battery packs’ throughput, lifetime, and safety.

“Creating sustainable battery solutions is our primary goal and mission statement,” says Cammi. “One of our main focuses is to use our technology in SLB applications. We can take used batteries, for example, from retired EV applications, integrate our hardware/software solution, and redeploy them as energy storage for at least another 10 years. We can do this in an effective way thanks to our architecture and its benefits — throughput management, lifetime extension, and improved safety.”

Element Energy’s BMS can give new life to EV batteries nearing the end of their life cycle or that have been rejected by an original equipment manufacturer (OEM). Once the batteries are refurbished and remanufactured, the energy goes back into the grid, typically to private energy providers. This circular economy approach to SLB storage achieves up to 40% of the total cost of battery usability over its lifetime, according to the company.

Element Energy’s BMS can give new life to electric vehicle (EV) batteries that are nearing the end of their life cycle or have been rejected by an original equipment manufacturer (OEM).

Element Energy’s circular economy approach to second-life battery (SLB) storage achieves up to 40% of the total cost of battery usability over its lifetime, according to the company.

Element Energy has reserved more than 2 gigawatt hours (GWh) of SLB storage.

To date, Element Energy has reserved more than 2 gigawatt hours (GWh) of SLB storage and recently installed a 53 megawatt hours (MWh) SLB plant in Texas — the largest grid of its kind, the company says. To put that amount of power into perspective, think of it in kilowatt hours. A 53 MWh-plant has a capacity of 53,000 kWh, and Element Energy’s plant uses roughly 900 retired EV battery packs. Now, consider that 2 GWh is 2 million kWh — almost 34,000 retired EV battery packs.

Element Energy’s plant in Texas with 53 megawatt hours (MWh) of SLB storage

Applying Simulation to BMS Solutions

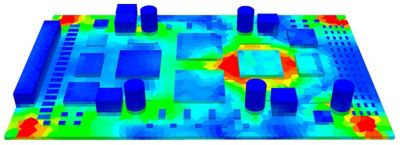

Ansys multiphysics simulation is a large component of Element Energy’s BMS design process. The team uses Ansys Mechanical structural finite element analysis software to perform structural analyses on battery components, such as battery packs and BESS containers. Typical simulations include static and dynamic loading, vibration and modal analyses, and printed circuit board (PCB) thermal analyses to support studies conducted in Ansys Sherlock electronics reliability prediction software.

A thermal-mechanical analysis performed in Ansys Sherlock electronics reliability prediction software

Sherlock software is used on all PCBs for reliability predictions. Using the tool, the group determines the conditions for qualification thermal and mechanical stress cycles based on corresponding acceleration factors and estimates the BMS lifetime.

“The ability to predict the reliability of individual components also allowed us to identify weak links and adjust the design accordingly,” says Cammi.

Electronics simulation is deeply integrated into the team’s design process. Aside from the Sherlock tool set, the team uses Ansys Q3D Extractor parasitic extraction electromagnetic (EM) simulation software, the Ansys Maxwell advanced EM field solver, and Ansys SIwave PCB and package EM simulation software to support PCB electrical design, with a specific focus on optimizing power conversion stage losses and magnetic component design. In addition, the team uses Ansys Icepak electronics cooling simulation software for electrothermal analyses and electronics cooling on PCBs.

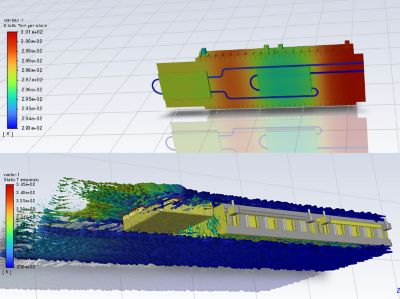

Engineers at Element Energy simulate battery liquid cooling (top) and battery pack cooling (bottom) using Ansys Fluent fluid simulation software.

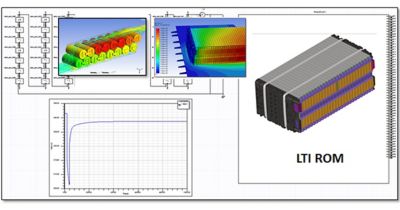

Outside of structures and electronics, Element Energy engineers assess computational fluid dynamics (CFD) using Ansys Fluent fluid simulation software. Main uses for the Fluent tool set include thermal simulation for PCBs and battery modules, air and liquid cooling container-level optimization, and electrochemistry simulation using a lithium-ion battery module.

“The accuracy of the simulations allows us to get to the prototyping phase with systems that are already much closer to the final product,” says Cammi. “I would estimate that we are saving 50% in product development time by shortcutting the transition from prototyping to final product.”

The company sees additional benefits during compliance assessments.

“The same goes for reliability and qualification tasks. Sherlock simulations have allowed us to identify potential problems before starting the qualification tests,” he adds. “Qualification tests can be very expensive and take quite a bit of time — up to a quarter. Being able to detect and address problems prior to kickstarting the qualification phase has been a lifesaver for us.”

Achieving Sustainability With Simulation

Element Energy is committed to creating a circular economy for battery solutions to improve sustainability and considers simulation a major player in reaching these goals.

“The environmental impact of battery reuse in terms of carbon dioxide (CO2) saved and reduced waste material is huge and will become even larger as the world moves more and more toward electrification,” says Cammi. “As mentioned above, Ansys is a big part of our design process, and consequently it is helping us in fulfilling our mission goals.”

In addition to Ansys simulation and the Ansys Startup Program, Cammi credits the KETIV team for its contributions.

By creating sustainable battery solutions, Element Energy supports a circular economy.

“KETIV has been very supportive over the past four years,” he says. “KETIV engineers have been helping us in solving technical problems, as well as in optimizing our workflow and simulation infrastructure, such as helping to set up distributed computing resources and so on.”

To explore Ansys solutions for battery management, visit Battery Modeling and Simulation Software at Ansys.

To learn how Ansys can support your early-to-mid-stage business, visit the Ansys Startup Program.

Just for you. We have some additional resources you may enjoy.

“The accuracy of the simulations allows us to get to the prototyping phase with systems that are already much closer to the final product. I would estimate that we are saving 50% in product development time by shortcutting the transition from prototyping to final product.”

— Corrado Cammi, vice president of engineering, Element Energy