-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

Have you ever broken a bone in your leg, perhaps when you were a child? If you did, you might remember how difficult it was to do everyday activities. But after a few weeks, you would be able to bear weight on it, and then a few weeks after that, the cast would come off. Now imagine how hard it would be if you could never bear weight on that limb again.

This is the reality for the 65 million amputees around the world, the majority of whom have lost lower limbs. The main reasons for amputation are traumatic events like car accidents, vascular diseases like diabetes, and inadequate medical care. Of the 65 million, 65% live in lower-to-middle-income countries, yet only 5% to 15% have access to assistive products due to unavailability and unaffordability. Locally produced prosthetics in low-to-middle-income countries are extremely limited, which forces hospitals to import them. This subjects patients to long wait times, inefficient and costly procurements, and logistical challenges.

Unfortunately, prosthetic users are often discriminated against and isolated from their communities. Amputations can lead to loss of employment, and many people may be unaware of their local resources and rehabilitation options. Even if they do know what resources are available, many amputees can’t logistically travel to receive them because of geographical challenges or the inability to afford them.

To combat these challenges, Circleg — a Swiss-Kenyan social enterprise — enables accessible, high-quality, and empowering solutions for amputees with a focus on beneficiaries in low- and middle-income countries. Circleg enables the freedom of mobility by providing prosthetic components and facilitating services, which further scales the impact. The organization develops solutions to support amputees in their path to regain mobility, thinking beyond the mere supply of high-quality prosthetics to integrate amputees and orthopedic technicians in the process.

The Circleg One and its components

Circleg’s journey began in 2018 through the bachelor’s thesis of Fabian Engel and Simon Oschwald as they completed their studies in industrial design at Zurich University of the Arts. Circleg now has five co-founders and a team of 18 engineers, designers, prosthetists, and business specialists. The flagship product, the Circleg One, is engineered to meet the unique needs and challenges faced by amputees. This state-of-the-art prosthetic device is set to bridge the gap by offering a solution that is high quality and accessible to enhance the lives of amputees.

“We are not reinventing the wheel, as mechanical prosthetics have been around for decades,” says Max Calabro, product developer at Circleg. “Our innovation consists of the implementation of processes and materials that have not been used before with the goal of improving the performance of low-cost prosthetics.” The Circleg One is a modular prosthetic consisting of four components, and it is customizable for both above- and below-knee amputees with simple tools and minimal effort. The use of reinforced plastics makes the prosthetic lightweight and comfortable for everyday activities.

Photo by Henry Robinson

To achieve this, Circleg uses Ansys Mechanical structural simulation software accessed through Ansys Apex Channel Partner CADFEM via the Ansys Startup Program. “The main challenge is that we have to meet many different requirements,” says Calabro. “The device needs to be easy and comfortable to use, there are really high mechanical requirements, and at the same time, we have a strong focus on production costs.”

Throughout the development process, Circleg used Mechanical software to evaluate the performance — such as the flexibility of the foot — and the strength of the Circleg One. Requirements for the Circleg One vary depending on if the amputee needs an above- or below-knee prosthesis. In general, an above-the-knee prosthetic leg is more complex than one below the knee, with the biggest difference being the knee joint. A below-the-knee prosthesis needs only a shin, an ankle, and a foot while an above-the-knee prosthetic leg needs a functioning knee joint. Without this, the wearer will have a hard time getting around. Knee joints are central to the mechanics of walking, as they bear much of our weight and affect our balance.

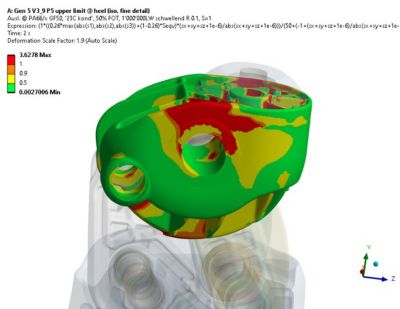

The finite element analysis of the knee in Mechanical software corresponds with the prototype fracture.

“There are very clear structural requirements, and our simulations helped us to have a precise estimate if the parts are going to meet them or not even before we built a tool for them,” says Calabro. Using simulation enabled him and his team to evaluate the performance of different components before physically creating them, significantly reducing time.

In the beginning, Circleg started small with simple models that reflected the different components of the prosthetic. “This helped already a lot. Moving forward, we realized that we need to make them more specific and precise,” says Calabro. Initially, the team hadn’t considered simulating the production process, but after seeing discrepancies between the simulations and actual measurements, the team implemented it on a larger scale. “When we made a more sophisticated model integrating material characteristics given by the injection molding process, we could tackle and improve the remaining problems and meet the strict mechanical requirements in the end,” he says.

Deformation animations analogous to the test bench tests were created in partnership with CIMCOM Engineering.

Empowering Others Through Sustainability and Inclusivity

In addition to providing low-cost, high-quality prosthetics, sustainability is top of mind at Circleg. The parts are developed with the principles of a circular economy in mind. Because the Circleg One is modular, the individual components can be substituted out or fixed instead of replacing the entire prosthetic. Once the prosthetic reaches the end of its lifespan, the components are meant to be collected, then reinserted into the material cycle so nothing goes to waste.

But perhaps the most important part of Circleg’s mission is supporting amputees. Over the years, Circleg has launched campaigns about amputees and their achievements. In the latest campaign, “Unstoppable,” Circleg released a short film to reimagine how society views disability. The story showcases the dynamic, empowering narrative that places humanity above labels.

Learn more about the Ansys Startup Program and Mechanical software.

Just for you. We have some additional resources you may enjoy.

“There are very clear structural requirements, and our simulations helped us to have a precise estimate if the parts are going to meet them or not even before we built a tool for them.”

— Max Calabro, product developer, Circleg

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.