Regardless of your occupation or industry, there’s a modern-day unifying truth: Artificial intelligence (AI) has the potential to transform your workflow, if it hasn’t already. Particularly for engineers, designers, and others who incorporate simulation into design and development to optimize products, AI presents a unique opportunity to enhance this optimization even further.

By combining the power of AI with cloud computing, Ansys’ latest AI-based technology, the Ansys SimAI platform, enables you to reach greater levels of innovation at a rapid pace. With the SimAI physics-neutral and cloud-native platform, you can train an AI model with previously generated Ansys or non-Ansys data and assess the performance of a new design within minutes across a wide range of engineering domains, including electronics, structures, and fluids.

The software-as-a-service (SaaS) application combines the predictive accuracy of Ansys simulation with the speed of generative AI via the cloud. The combination boosts model performance by 10-100X across all design phases for computation-heavy projects. Let’s explore how the SimAI application optimizes design from chips to ships in four different scenarios.

The Ansys SimAI application boosts the prediction of model performance by 10-100X across all design phases — delivering simulation results in minutes, not hours.

Enhance Chip Design

Chip design requires complex engineering that frequently involves nonlinear, unexpected behavior. Simulation analyses often provide critical insight into electrical, thermal, and structural characteristics to not only inform design, but also improve efficiency, accelerate development, and ensure verification. Still, for fast design iterations, even the most robust simulation workflow can feel like it’s holding you back and is just too time consuming.

That was the case for a recent team seeking a faster way to explore chip design. Their existing approach slowed them down due to a dependence on domain discretization and the number of elements required in chip modeling. It also offered limited scalability. A slight change to the model or hiccup in the process significantly increased simulation time. In addition, it was difficult to efficiently represent and map spatial distribution uncertainty and variations in chip parameters, including die size and heat transfer coefficient (HTC) values.

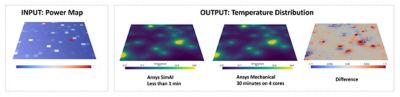

The SimAI platform optimizes chip thermal reliability assessment, including a consistent prediction of temperature maps 20-80X faster across design alterations than conventional simulation techniques.

By integrating Ansys Mechanical Parametric Design Language (MAPDL) and the SimAI tool, the team was able to overcome hurdles, assess chip thermal reliability earlier in the design process, and speed up their workflow. MAPDL is a scripting language that interacts with the Ansys Mechanical finite element analysis (FEA) solver to automate simulation tasks and streamline workflows.

Essentially, the SimAI application is engaged in three simple steps: upload data, train an AI model, and predict. Using simulation results from Ansys Mechanical, the team created an AI model based on 2,250 diverse chip thermal simulation datasets. With this insight, the application swiftly predicted a temperature distribution map within one minute. The maximal temperature difference between ground truth and prediction is less than 0.5%. The AI prediction accurately pinpointed the thermal critical locations.

Key benefits of the SimAI tool for chip design and thermal reliability assessment include:

- Quick evaluation of an on-chip thermal solution that is approximately 20X faster than conventional simulation techniques, as well as expedited analyses of various system scenarios.

- Accelerated and consistent prediction of temperature maps across design alterations, approximately 20-80X faster.

- Elimination of tedious adaptive volume meshing tasks.

- Expedited development life cycle for next-generation chip design.

Boost Engine Brackets

In aerospace applications, structural analysis can be just as important as aerodynamic assessment, even for the smallest parts. Consider jet engine brackets, also known as loading brackets. They may seem minor compared to the engine itself, but they are essential components because they support the weight of the engine.

Consequently, developing new jet engine bracket designs that meet weight and robustness structural requirements and constraints is a challenging process. It’s helpful to reference existing designs, drawing knowledge from previous projects. The SimAI application helps with this workflow, too.

Using a multitool workflow, including the capabilities of Ansys Discovery 3D design modeling and Ansys optiSLang process integration and design optimization software, one team built an AI model using about 250 training samples, which included different and topologically diverse bracket designs. With insight from past simulations, the application predicted the behavior of a new shape in less than a few seconds. For future projects, the same AI model can be retrained using different designs to capture new insights.

Discovery 3D modeling software can accurately and rapidly simulate any design on the first attempt without training. The SimAI application can provide very rapid predictions within an already simulated design space to aid in optimization, sizing, and selection for applied scenarios. Leveraging both the Discovery and SimAI platforms, engineers can generate accurate data, enrich the training process, and produce pervasive insights into future product behavior.

Primary benefits of the SimAI application for jet engine bracket design include:

- Zero scraps and reduced material usage. Past designs are valuable, as even a failed design is a source of knowledge.

- Reduced workflow of up to 90%, with the ability to shift effortlessly between computer-aided design (CAD) and multiphysics simulation.

- Accessibility for 100% of the team, including nonexperts. Supported by AI guidance, team members no longer need a deep knowledge of physics.

The AI model provides a confidence level with each prediction. As shown in the chart, the confidence level increases with the amount of training samples.

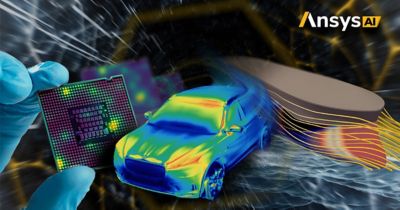

Rev Up Automotive Aerodynamics

As environmental concerns grow around the world, car manufacturers must meet increasing requirements to reduce carbon dioxide (CO2) emissions. Many reduction plans and guidelines, such as the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), require automotive manufacturers to assess the aerodynamic performance of all design variants in new car models.

Unfortunately, wind tunnel tests are a slow and costly solution, and speeding up development time to advance the next generation of electric cars is important. Faster simulated predictions of aerodynamic performance are crucial to meeting requirements, staying competitive, and keeping costs down.

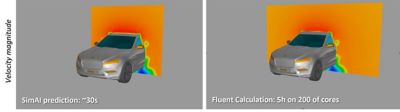

The SimAI platform was used in tandem with Ansys Fluent computational fluid dynamics (CFD) software to assess the aerodynamic performance of a sports utility vehicle (SUV). Using approximately 50 CFD results, the team created an AI model that included car exterior shape variations and topological changes, such as a rear mirror, ski rack, and spoiler. With the support of the AI-based application, predictions for new SUV geometry took less than one minute. In addition, the application’s drag error results compared to CFD results was less than a 0.5% difference. Accurate predictions were also generated for flow characteristics, including skin friction field and wake topology.

SimAI capabilities speed up automotive aerodynamic design by up to 10-100X faster.

Top benefits of SimAI platform for automotive aerodynamic assessment include:

- Increased design alternatives assessment — 20X more compared to traditional simulation methods — and quicker design optimization.

- Accelerated and consistent prediction of aerodynamic performance across design changes that is 10-100X faster, even when the geometry structure is inconsistent by leveraging previous CFD simulations used in earlier design phases or previous car generations.

- Quicker design process and reduced costs by “shifting simulation left,” i.e., incorporating simulation earlier in the process. This enables designers to incorporate fast and meaningful aerodynamic predictions throughout all design stages.

Inform and Accelerate Ship Hull Design

Similar to the automotive industry, shipping companies are being encouraged to reduce emissions. One example is the push from the International Maritime Organization (IMO) to reduce emissions from international shipping. To achieve this, one method is to improve ship resistance by optimizing the hull form, which directly translates into energy efficiency and fuel savings. However, fast and efficient simulations are needed to evaluate several hull designs at once with many different variables.

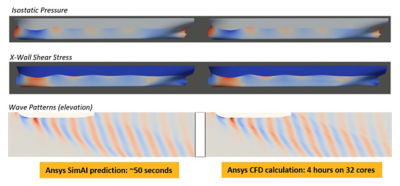

Employing the SimAI tool, engineers created an AI model using 288 CFD results that included hull shape variations and operational conditions such as draft and boat speed. In less than one minute, the tool predicted new and optimized hull geometry. In addition, the tool’s resistance error results were less than 5% compared to the CFD simulation results and the wave pattern prediction was fully accurate.

The main benefits of the SimAI tool in ship hull design include:

- Accelerated performance assessment of new hull designs in a few minutes instead of days.

- Informed decision making in the early stages of design.

- Time savings for value-added tasks like design exploration, which creates more time to innovate.

To learn more, download the white paper, “How to Improve Hull Designs With Ansys SimAI.”

By combining traditional simulation methods like computational fluid dynamics (CFD) with the SimAI tool, you can predict new geometry for ship hull design in less than a minute.

Embrace AI-powered Simulation

AI and machine learning (ML) methods are being applied to design and development in a wide range of industries from semiconductors and aerospace to automotive and maritime. By integrating AI/ML with simulation and computer-aided engineering (CAE), teams from diverse fields can solve multiphysics and engineering challenges more quickly and accurately, enhancing design exploration and optimization. As illustrated in the previous scenarios, this AI/ML-powered optimization leads to more efficiency, cost savings, and, ultimately, better products.

The SimAI application enables both engineers and designers to leverage their previous simulation and measurement data to train and build a surrogate AI model. By using this AI model, they accelerate the design process with assessments that take minutes, not hours or days.

To learn more about how the platform can optimize your designs from chips to ships, register for the upcoming webinar series, “Accelerate Your Simulation with AI.”