-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

DETTAGLI DELL'ARGOMENTO

Che cos'è un MicroLED?

Le tecnologie di ottica e fotonica stanno evolvendosi rapidamente in applicazioni correlate ai display. I TV OLED sono attualmente il più grande mercato commerciale, ma i microLED sono considerati la nuova generazione di display a LED grazie a migliori tempi di risposta, minore consumo energetico, maggiore efficienza energetica e risoluzione superiore.

Che cos'è la tecnologia MicroLED?

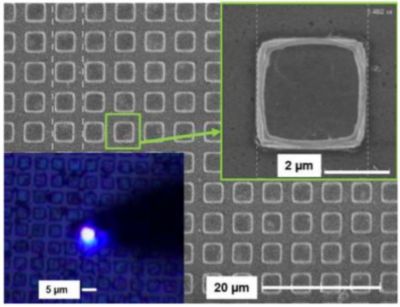

I microLED (μLED) sono dispositivi delle dimensioni micrometriche realizzati in composti III-V, elementi sulla terza e quinta colonna della tavola periodica, come il nitruro di gallio indio (InGaN) e il fosfuro di gallio indio di alluminio (AlGaInP). I microLED sono piccole sorgenti luminose piatte e quadrate che possono essere integrate in array con un contrasto molto elevato. Ogni LED in un display microLED agisce come un pixel (rosso, verde o blu) e può essere utilizzato in TV microLED e altre tecnologie che richiedono display avanzati.

LED piatti e quadrati

I microLED funzionano diversamente dai display basati su LCD. I sistemi LCD tradizionali utilizzano una retroilluminazione a LED e uno strato di cristalli liquidi che crea immagini bloccando determinate parti della luce. Al contrario, sia i display microLED che OLED sono molto più semplici perché non fanno affidamento su LCD. Ogni LED emette invece la propria luce, creando l'immagine da ogni singolo pixel.

Come vengono fabbricati i microLED?

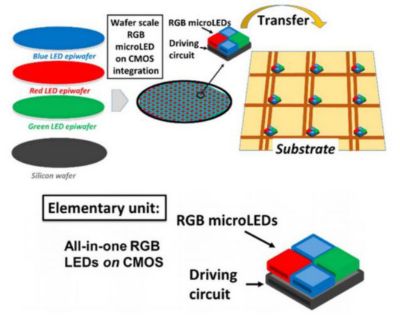

In uno scenario ideale, la crescita epitassiale, o la crescita dei LED direttamente sul backplane, tramite integrazione monolitica sarebbe il percorso di fabbricazione migliore per i microLED. Attualmente si tratta di un'area in sviluppo in cui le aziende stanno creando strategie di prototipazione, ma i costi attuali per eseguire questi metodi sono troppo alti per essere commercialmente fattibili.

Oggi, i microLED sono più comunemente fabbricati utilizzando il metodo di trasferimento "pick-and-place", ossia raccolta e posizionamento. In questo approccio, i LED rosso, verde e blu sono fabbricati direttamente su un wafer e quindi trasferiti singolarmente al backplane, che contiene un substrato e le parti elettroniche necessarie per controllare la luce. Il processo di trasferimento di massa deve essere rapido, preciso e affidabile per garantire che tutti i LED siano correttamente allineati al backplane.

Processo di trasferimento "pick-and-place"

Nonostante le sfide della produzione su larga scala, LG, Sony e Samsung stanno sviluppando grandi TV a microLED di alta qualità. Tuttavia, è necessario risolvere diverse problematiche di progettazione e scalabilità prima che diventino disponibili per il consumatore medio. Al momento, questi televisori sono molto costosi a causa del processo di fabbricazione "pick-and-place", dispendioso in termini di tempo e denaro.

Sfide di progettazione nella fabbricazione di microLED

La tecnologia microLED non è ancora matura e i progettisti possono utilizzare diversi metodi di fabbricazione dei semiconduttori nel processo di fabbricazione. Alcune considerazioni chiave per gli sviluppatori nella progettazione di microLED sono:

- Emissione incoerente a livello macroscopico in array di pixel di grandi dimensioni. Per evitare che ciò accada, i progettisti possono utilizzare altri elementi ottici come filtri, lenti, strati di conversione del colore, strutture di dispersione, polarizzatori e reticoli per migliorare la definizione del colore del display.

- Requisiti di tolleranza più rigorosi per LED di dimensioni più piccole. La tolleranza per le modifiche delle dimensioni e il disallineamento diventa più restrittiva per i LED di piccole dimensioni, soprattutto a maggiore densità di pixel.

- Difetti e imperfezioni su scala atomica ai bordi di un LED, che possono ridurre l'efficienza interna del dispositivo.

- Maggiore richiesta di driver TFT (Thin Film Transistor, transistor a pellicola sottile) altamente compatti, efficienti dal punto di vista energetico e complessi per adattarsi alle dimensioni dei subpixel più piccoli. I subpixel contengono gli elementi RGB necessari per creare il colore nei display, quindi i TFT devono controllare ogni pixel in modo rapido e preciso.

- Evitare difetti che possono verificarsi in qualsiasi fase della produzione. I processi di fabbricazione possono ancora generare pixel morti da considerare.

Come si confrontano i microLED con altre tecnologie LED?

Negli ultimi anni, i display OLED e la tecnologia OLED sono diventati lo standard di riferimento, ma come possono essere messi a confronto con i microLED? Esistono molte metriche diverse per la misurazione delle prestazioni di OLED, microLED, LCD e mini-LED. Nel complesso, la struttura più semplice della tecnologia microLED genera un'immagine di qualità superiore perché ha un rapporto di contrasto più elevato e un tempo di risposta più rapido. I display microLED possono anche essere resi flessibili come i display OLED.

I microLED si distinguono dalle altre tecnologie LED per:

- Pixel più piccoli e luminosi con una gamma di colori migliorata. I microLED hanno una luminanza di oltre 100.000 nit rispetto ai 500-1.000 nit per gli OLED e 3.000 nit per gli LCD. Alcuni display microLED possono raggiungere livelli di luminanza superiori a 250.000 nit. Una maggiore luminanza non provoca minore efficienza, invecchiamento o effetti termici avversi.

- Circa 10% di miglioramento teorico di efficienza quantistica esterna (EQE) rispetto agli OLED

- Maggiore durata, poiché i materiali inorganici producono LED di lunga durata rispetto ai materiali organici

- Resistenza a ossidazione e altri effetti ambientali

- Gamma di temperature d'esercizio più ampia (da -100 a 120 °C)

- Migliore visibilità alla luce del sole e più angoli visivi

- Tempi di risposta rapidi nell'ordine di nanosecondi rispetto a microsecondi o millisecondi

- Il potenziale (dei LED blu) di diventare la sorgente di eccitazione per i punti quantistici all'interno di TV QLED

Quali sono le applicazioni dei microLED?

Nonostante non sia una tecnologia matura a livello commerciale, l'ulteriore aumento delle prestazioni rispetto ad altre tecnologie a LED, soprattutto in termini di luminosità, flessibilità, qualità delle immagini e durata, ha aperto i microLED a una gamma di tecnologie di display avanzate. Alcuni esempi chiave di utilizzo dei microLED sono:

- Tecnologia indossabile, come smartwatch e braccialetti per il fitness

- TV microLED

- Occhiali e visori per realtà aumentata/virtuale (AR/VR)

- Heads-up display (HUD) nei settori automobilistico e aerospaziale

- Display del quadro strumenti centrale

- Fari automobilistici

- Comunicazioni basate sulla luce ad alta velocità

- Display flessibili e allungabili

Simulazione di microLED con Ansys

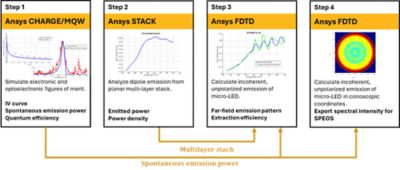

Gli ingegneri possono superare le numerose sfide di progettazione dei microLED utilizzando prima metodi di simulazione per visualizzare il comportamento del LED o del display. ANSYS offre una gamma di strumenti per simulare le prestazioni dei microLED prima della fabbricazione fisica:

Solver Ansys Lumerical STACK: simula i diversi strati di materiale nei microLED per mostrare come la luce viene riflessa, rifratta e trasmessa attraverso di essi. Il solver STACK calcola anche la potenza emessa e la densità di potenza dei LED.

Solver Ansys Lumerical FDTD: simula modelli di emissione in campo lontano ed efficienza di estrazione dei LED. Il solver FDTD calcola anche l'intensità spettrale in coordinate conoscopiche per l'uso con gli strumenti di progettazione Ansys Speos.

Solver Ansys Lumerical CHARGE e Ansys Lumerical MQW: simulano la curva corrente-tensione (I-V), lo spettro di potenza di emissione spontanea e l'efficienza quantistica interna dei LED.

Panoramica del flusso di lavoro per i solver Lumerical Ansys

Software Ansys Speos: consente di eseguire simulazioni a livello di sistema utilizzando i dati di intensità spettrale dei solver della suite Lumerical e funge da laboratorio fotometrico virtuale. Consente agli ingegneri di esaminare l'intero spettro di colori ed eseguire test radiometrici.

Scopri come puoi superare le sfide di progettazione nella tecnologia microLED prima di affrontare il complesso processo di fabbricazione contattando il nostro team tecnico.

Risorse correlate

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.