Exploring Metal Additive Manufacturing Processing Parameters in Ansys Granta EduPack

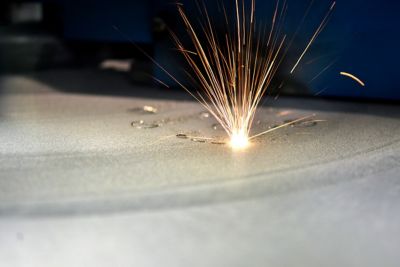

Explore the intricacies of Laser Powder Bed Fusion (LPBF) in metal 3D printing, delving into critical processing parameters like laser power, scanning speed, hatch spacing, and layer thickness. Discover the impact of Laser Energy Density (LED) on porosity, material properties, and microstructure, as well as its role in shaping defects such as micro-cracks and spattering. Ansys Granta EduPack's "Additive manufacturing: metal powder bed fusion" folder provides 35 datasheets, offering a hands-on exploration of the effects of LPBF parameters on metallic alloys like Inconel 625, SS316L, AlSi10Mg, and Ti64. Gain valuable insights for optimizing the LPBF process, ensuring flawless, high-quality metal components.

Learning Outcomes

- Understanding of LPBF processing parameters

- Critical thinking for AM process optimization

- Navigating laser energy density vs defects

Applicable Courses for Use

- Digital manufacturing technologies

- Metal AM: from theory to practice

- Intro to 3D printing processes & theory

- Near-Net-Shape Manufacturing