Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

“I’m quite sure we wouldn’t have achieved ablation without the optimizations we performed in OpticStudio. We wouldn’t have generated any meaningful data.”

— Raoul Lorbeer, Research Scientist / Institute of Technical Physics, German Aerospace Center

In 2020, the Institute of Technical Physics (ITP) embarked on a project to prototype a new technology for maneuvering miniature satellites. Using Ansys Zemax OpticStudio, ITP conceived its design for laser-ablative propulsion and successfully demonstrated its viability under the strict requirements of satellite miniaturization.

Challenges

The ongoing miniaturization of satellites has reached the level of a CubeSat. Developing a single-unit CubeSat is challenging because its thrust mechanism should essentially contain no moving parts, consume no more than 2 watts of power, and make at least half of its volume available for other essential hardware. ITP sought to design a thruster that would fit inside a single-unit CubeSat and use laser-ablative propulsion. The team’s goal was to achieve thrust using a highly efficient, navigable system based on precision optics that would guide and control the laser activities and be a reliable source of propulsion for the satellite itself.

Engineering Solution

One risk when building laser-ablative optics is contamination of the optical components by the ablative material. To mitigate this risk, ITP’s optical design included a toroidal ellipsoid mirror that reimages the center of the deflected beam to a new location. This additional step introduced aberrations in the beam that significantly diminished the focus efficiency required for ablation. To design a custom aspheric lens to correct this, ITP used the modeling functions in OpticStudio to experiment until finding the best possible result. The team also used the OpticStudio stock lens catalog and merit function editor to select and optimize several components within the design, entering parameters they knew would be necessary to adjust in a laboratory setup.

ITP’s system can now perform 3D laser ablation of various materials, and it can be powered using a standard USB port. With help from Ansys, the team achieved success at proving the viability of laser-ablating material within a compact thrust system suitable for adoption in CubeSats.

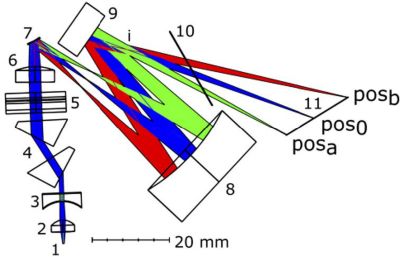

The ITP laser-ablative thruster design in OpticStudio. Optical components are shown in black; 0° MEMS mirror deflection angle beam path is shown in blue; and ±4° MeMS angle beam paths are shown in green and red. Source: CC BY (Creative Commons Attribution 4.0License) Toni Bauer, Sebastian Weixler, Raoul-Amadeus Lorbeer, and Hans-Albert eckel, “uSB-powered technology platform for laser ablative thrust generation,” OSA Continuum 4, 1304–1315 (2021).

OpticStudio spot diagram simulations for the three example beam positions indicated in Figure 1. The dots show the intersection of ray-tracing rays with the scanning plane at each angle, relative to the expected airy diameter. Source: CC BY (Creative Commons Attribution 4.0 License) Toni Bauer, Sebastian Weixler, Raoul-Amadeus Lorbeer, and Hans-Albert eckel, “uSB-powered technology platform for laser ablative thrust generation,” OSA Continuum 4, 1304–1315 (2021)

Benefits

- Designing custom aspheric optical elements using OpticStudio simulation tools.

- Simulation toolchain integration for effective software-based system modeling.

- Merit function tools for system optimization to systematically achieve a perfectly collimated beam.

Results

- Proved the viability of laser ablation as a thrust technology for nanosatellites.

- Achieved thrust generation within single-unit CubeSat limitations.

- Prototyped, miniaturized, and optimized complex optics that can be easily exported to CAD.

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.