Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

3D Printing Corporation, K.K. (3DPC), based in Japan, helps manufacturers develop alternative supply chains by providing a one-stop shop for strategic 3D printing services. Inspired to secure supply chains and prepare manufacturers for unexpected disruptions, 3DPC equips manufacturers with additive manufacturing (AM) parts and services to optimize and digitalize their workflows. 3DPC works with various industries and markets, from toy companies to space stations.

Challenges

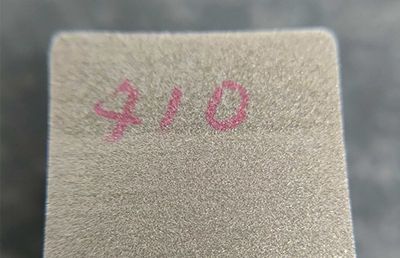

3DPC works with a wide range of materials, including resins, metals, and composites. Predicting deformation is essential in AM to build parts successfully, keep costs down, and avoid mass printing errors. 3DPC uses Ansys’ multiphysics simulation tools to analyze and predict thermal deformation in advance and modify parameters. It is also important to balance the strength and weight

of parts. Clients seek strong parts, but also require them to be lightweight. 3DPC approaches this using a fused deposition modeling (FDM) method and integrates Ansys’ tools to optimize the process and achieve better results.

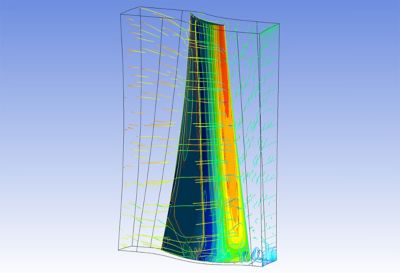

Designers at 3DPC use Ansys Fluent to analyze the fluid flow surrounding a centrifugal airfoil

Engineering Solution

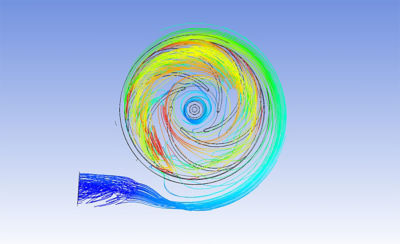

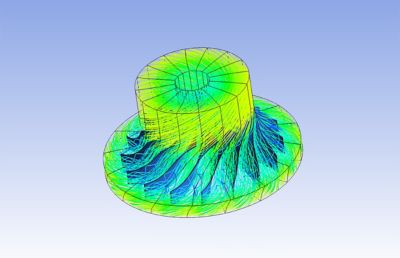

To improve the strength and weight of existing parts, 3DPC enhances the FDM method by using Ansys Mechanical and applied topology optimization to reduce part weight while maintaining strength. The team evaluates strength considering the anisotropy of the FDM method and applies this to the topology-optimized model. In one example using this approach, 3DPC successfully reduced weight by 20% without reducing strength. The team accomplished this using Ansys’ simulation capabilities to repeatedly change settings and parameters such as boundary conditions. For thermal analyses, 3DPC integrates Ansys Fluent to evaluate heat exchange efficiency and Ansys Additive Suite to predict thermal deformation using a powder bed fusion (PBF) method. Additionally, 3DPC evaluates the shock absorption performance of elastomer materials using Ansys LS-DYnA and analyzes mesh data with Ansys Discovery.

Ansys Fluent simulation of the fluid flow around a centrifugal pump

Ansys Fluent simulation of the fluid flow around a centrifugal pump impeller

With critical insights from Ansys simulation, 3DPC can detect possible defects, including porosity in metal, which is often caused when air is trapped during processing

Benefits

- By using Ansys’ tools, 3DPC reduces part weight (up to 20% in one example) and reduces material costs by using less material.

- 3DPC produces higher quality parts and services by applying Ansys’ multiphysics analyses and critical insights

- Ansys’ fast simulation results enable 3DPC to reduce time of sale, accelerate production processes, and secure new customers, increasing its return on investment (ROI).

- Ansys simulation helps 3DPC quantify the hardness and/or softness of AM parts such as lattice cushions to improve parts and present stronger proposals to clients with the ability to illustrate part characteristics using simulation.

Scopri cosa Ansys può fare per te

Scopri cosa Ansys può fare per te

Contattaci subito

Grazie per averci contattato!

Siamo qui per rispondere alle tue domande e non vediamo l'ora di parlare con te. Un membro del nostro team di vendita Ansys ti contatterà a breve.