-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

February 7, 2022

An Introduction to Aeroacoustic Simulation

Hear that? A plane flying over a neighborhood. The fan on your laptop. Acres of spinning wind turbines. All around us, machines are making noise. How much noise is too much? How far does the sound travel? Where, exactly, is all this noise coming from?

Aeroacoustics simulation, the study of sound generated from a flowing fluid, is how engineers and designers identify the origin of a noise, understand its range of impact, and model solutions to reduce or eliminate the noise to comply with sound regulations and improve user experience.

Across industries, aeroacoustics simulation helps engineers analyze the generation of sound to improve comfort and safety. For example, in manufacturing, simulation can help identify hearing-loss hazards caused by the close proximity of equipment to operators. In marine turbines, it can help protect sea life by identifying ways to reduce underwater noise pollution.

In this article, we’ll look specifically at automotive, where thousands of parts are being constantly impacted by flowing air. Here, aeroacoustics simulations can quickly identify the source of a sound and explore ways to silence it.

Aeroacoustics Use Case: Automotive NVH Analysis

As a passenger rides in a car, they can perceive a variety of sounds that contribute to overall noise — all of which provide their own challenges for modeling.

Figure 1: Noise sources in an Alfa Romeo Giulietta aeroacoustics simulation.

- Tire noise: Noise from the rotation of the tires contributes to external flow aerodynamic noise.

- Challenge: Modeling the interaction between a deformed tire and the road.

- Wiper noise: The noise from wiper movement contributes to external flow aerodynamic noise.

- Sunroof noise: When a vehicle is traveling with the sunroof or side window open, a resonance between the cabin acoustics and pulsating vortices crossing the opening can occur, generating a so-called “buffeting” noise.

- Challenge: Accurately predicting the turbulence structures of the flow reaching and crossing the opening, which has a strong dependency with speed conditions and geometry details.

- HVAC system noise: The noise from a car’s heating, ventilation, and air conditioning (HVAC) system contributes to overall perceived noise levels and has a major impact on passenger cabin comfort.

- Challenge: Completing a transient study with rotating components, accurate turbulent flow field resolution, and noise propagation up to the driver’s ear.

- Door gap noise: The flow-induced pressure fluctuations in a door gap cavity generates cavity noise.

- Side mirror and window noise: Noise is generated from turbulent flow impinging on the window glass generated by the car’s surfaces and side mirror design.

How can Simulation Reduce Automotive Noise?

Aeroacoustics simulation helps predict the combined impact of noise sources on the overall sound level in specified locations — for instance, the driver’s seat. Being able to predict noise enables designers to make modifications on car details (e.g., side mirror shape, some door gaps, vents, etc.) and materials to comply with regulations and improve the comfort of the passengers.

Ansys Fluent can solve complex aeroacoustics problems and provide an extensive set of modeling options and post-processing capabilities to improve acoustic design using a variety of methods:

- Broadband noise methods, where the steady solution is used as basis for noise source estimation.

- Acoustic analogy methods, where the computational fluid dynamics (CFD) solution is decoupled from the sound propagation via wave equation solutions.

- Direct methods (i.e., direct computational aeroacoustics), which fully couple the calculation of unsteady flow and acoustic fields.

In the latest Ansys software release, 2022 R1, we have introduced a new acoustics workflow that couples Ansys Fluent CFD simulations to Ansys Sound. This enables engineers to use advanced acoustics analysis techniques to analyze the acoustic pressure signals computed by CFD, including:

- Sound files that let you listen to simulated sounds.

- Reports on volume, tonality, sharpness, and articulation.

- Translation of pressure signals to see acoustic indicators by location.

- Multiple frequency functions for sound composition.

How to do Acoustic Simulation in Ansys Fluent

During the solution setup in Ansys Fluent, it’s possible to define an array of receivers and propagate the noise sources to them. The new Sound Analysis module extends Ansys Fluent acoustics capabilities, enabling engineers to hear what you compute in your CFD simulation.

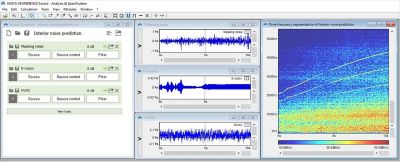

Figure 2: Sound Analysis in Ansys Fluent.

Even short acoustics signatures generated at receiver locations during CFD simulations can be turned into high-quality audible long files. In addition, psychoacoustic analysis tools can provide insight into the impact of predicted sounds on human ear perception. The acoustics analysis in Ansys Fluent also support Frequency Response Function, which allows users to:

- Switch from the computed isolated component noise (e.g., HVAC) to the prediction of that noise in the cabin (without having to simulate the cabin itself once the time-frequency representatio (TFR) has been given/evaluated)

- Compose the total sound from different sources (e.g., tires, wipers, HVAC, etc.).

With a single click, it’s possible to transfer the acoustic signals and launch more sophisticated acoustics analyses in Ansys Sound.

Figure 3: Sound Analysis in Ansys Sound.

To learn more, listen to the Aeroacoustics Simulations Webinar or visit the CFD simulation product page to see how the newest acoustics enhancements can be used for your simulation.