-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

February 10, 2021

Top 3 Features in Ansys Mechanical 2021 R1

In Ansys 2021 R1, Ansys Mechanical continues to deliver features that enable faster simulations, easier workflows and scripting with recording capabilities, as well as product integrations that offer enhanced solver capabilities.

Let’s look at the top three 2021 R1 features in Ansys Mechanical and how they will benefit users and improve the overall structural design process.

1. Short Fiber Reinforced Composites Workflow

Fiber reinforced plastics are everywhere, from consumer goods, automotive parts and airplanes to portable electronics. In 2021 R1, Mechanical enables engineers to:

- Accurately and easily simulate plastic parts made through injection molding

- Test for deformation of the plastic part

- Predict potential failure points of the part when used in a real-life scenarios

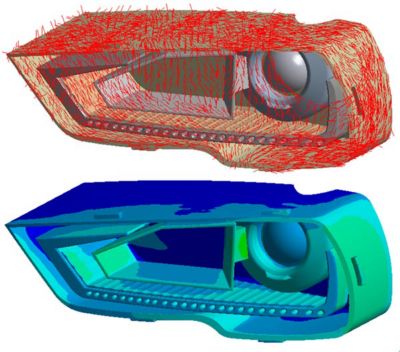

The injection process data that includes fiber orientation and density details are imported and mapped seamlessly onto a finite element mesh in Mechanical and complemented with accurate material behavior at each element. Moldflow, Moldex3D, Sigmasoft and Cadmould injection modeling software vendors are supported. Material data is captured through a multiscale analysis run with Ansys Material Designer to compute the complex plastic behavior. These computed materials can then be applied to whole parts or assemblies to accurately predict part performance ahead of any manufacturing or testing effort.

Ansys Mechanical can simulate fiber-reinforced plastic parts made through injection modeling processes such as automotive headlamps.

Ansys Mechanical in Workbench produces realistic analyses of new products designed with fiber-reinforced plastics, while considering real-life conditions. This results in an easier and quicker modeling process with no need for complex workflows.

Watch the webinar: Ansys 2021 R1: Ansys Mechanical Update

2. Back to CAD

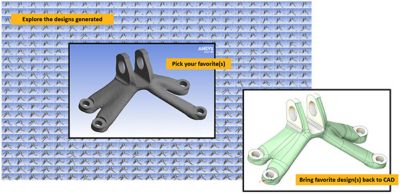

2021 R1 also brought the official release of the “Back to CAD” workflow within Ansys SpaceClaim. This new workflow allows users to turn their topology optimization results into computer-aided design (CAD) geometry. The “autoskin” feature saves the user time otherwise spent on recreating geometry. You can use the newly created geometry for validation simulations or continue on to prepare the part for additive manufacturing.

Ansys 2021 R1 enables you to explore thousands of designs, pick your favorite and then bring it back to CAD.

You can perform topology optimization in Mechanical using a range of tools and options there, including the level-set based solver. Ansys optiSlang can then be used to run many scenarios and options parametrically. You can also leverage Ansys Distributed Compute Services (DCS) to run large-scale evaluations and then bring the chosen candidates back to CAD with SpaceClaim. This workflow and toolset are the keys to generative design and unlock new design freedom.

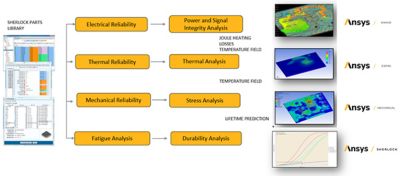

3. Product Integration for Enhanced Electronics Reliability Workflows

Throughout each release, we continue to integrate products into Mechanical to enhance and expand workflows. In 2021 R1, the Ansys Sherlock plug-in in Workbench allows users to access Sherlock automated design analysis software and incorporate Mechanical’s random vibration capability for ease of use and expanded capabilities within one interface.

Ansys LS-DYNA also continues to add solver capabilities to Mechanical software. Users can now perform electronic CAD trace mapping for analysis of printed circuit boards (PCBs) in electronics reliability workflows. Trace mapping is an approach that maps the PCB information from the ECAD file onto the mesh to simplify modeling. It can be applied to solids and shells. Additional capabilities included in Workbench and LS-DYNA feature solver version selector, solution monitoring while solving and result plot trackers.

To learn more about the latest features in Ansys Mechanical 2021 R1, watch the What’s New video below.