-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

May 18, 2022

Revolutionizing 3D Surface-Contact Detection via Deep Learning

Today’s headlines focus on the enormous potential of artificial intelligence (AI) and machine learning (ML) to enhance the performance and capabilities of leading-edge products like autonomous vehicles, robotics systems, and smart energy grids. But, behind the scenes, these technologies are also reshaping the way new products are developed, verified, and brought to market.

While Ansys has already integrated AI and ML into many of its software solutions, we continue to invest in research to move these technologies forward in the field of simulation. A previous blog post discussed the application of ML to help Ansys solvers represent product geometries in a more lightweight, spatially compressed manner that is numerically accurate, while requiring less computational time and resources.

But that’s just one example of how AI and ML are impacting the field of engineering simulation and Ansys software capabilities. Recently, I co-authored a paper with senior research and development (R&D) engineer, Rishikesh Ranade, that’s been accepted for publication by ASME’s Journal of Mechanical Design. The paper describes the capabilities of a new 3D architecture based on convolutional neural networks, or CNNs, a type of deep learning network typically applied to analyze visual imagery. Called ActivationNet, this architecture may soon be incorporated into Ansys structural and fluid solvers to improve the quality of detecting 3D surfaces in contact with one another.

Many structural problems involve accurately replicating how 3D surfaces interact, so physical phenomena resulting from that contact ― such as stresses, fatigue, and wear — can be confidently predicted. The challenge? Setting up high-quality contacts for a large assembly of bodies is very manual. While algorithms exist for automatic contact detection, they are not foolproof, and they often end up over-detecting or under-detecting contacts when dealing with assemblies that combine both large and small parts. In addition, contact detection during the non-linear solution of large assemblies is time-consuming. At Ansys, we are always looking for ways to improve speed within our solvers. Deep learning, and 3D CNNs in particular, are great at detecting local features in images — which inspired us to investigate their use for surface-to-surface contact detection.

Ensuring High-Quality Auto Contact Detection Before Simulation Begins

Because it’s impossible to fully replicate every physical detail of today’s intricate product designs in a time- and cost-effective manner, 3D surfaces are currently modeled using point clouds — a set of data points in space — or surface meshes that approximate the product’s geometry in a manner that’s numerically manageable. Auto contact detection algorithms work directly using surface mesh pairs, using features such as proximity/gap between surfaces, the angles between surfaces, and the overlap, or intersection, of surfaces with respect to each other.

However, because contact pairs are detected based on deterministic algorithms — with a single gap tolerance representing contacts for all interacting bodies — the result can be “bad contacts.” For example, surface pairs can have a large gap, some surface pairs might be perpendicular to others, or there may be a large angle between different surfaces. And, unfortunately, engineers have no easy, automated way to distinguish “good” contact models from lower-quality ones that should be improved before the simulation run begins. This process is very manual and time-consuming because engineers need to look at each pair, then accept or delete them after visualization.

To address this challenge, Ansys has developed a proprietary algorithm, ActivationNet, that assigns a quality score to each surface-contact model in the product design before any simulation is conducted. Engineers can flag these lower-quality surface-contacts and delete them before simulation to deliver accurate results.

How does the ActivationNet algorithm work?

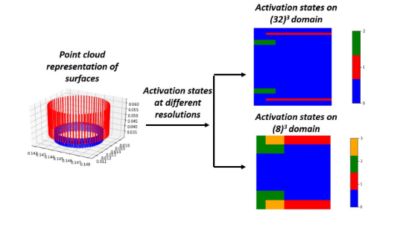

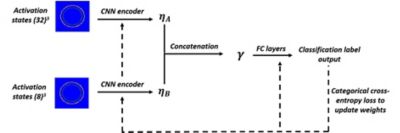

ActivationNet uses coarse point-based or mesh representations of contacting surfaces to generate a series of activation states on computational grids of different resolutions. The activation states are based on the spatial location and density of points in a normalized 3D space. These states are simply markers assigned to each pixel of the computational grid to represent the individual contacting surfaces, as well as the overlapping regions between them. These activation states are fed into deep neural networks that extract features equivalent to the “handcrafted” inputs ― for example, surface proximity and angle — that were initially defined by human engineers.

Because these neural networks work in probabilistic space, they exceed the capabilities of deterministic algorithms and rough meshing techniques to represent important and intricate characteristics of 3D surfaces — and they produce much more accurate assessments of how well surface interactions are modeled. These networks “learn” the characteristics of good surface-to-surface contact interaction and can accurately rate the quality of each interaction in the product model.

The ActivationNet algorithm uses the spatial location and density of points in a cloud or mesh to generate activation states.

Depending on the problem at hand, these activation states reflect the geometric model at a range of resolutions. The collected activation states, which represent contact-surface interactions, are handed off to neural networks for assessment.

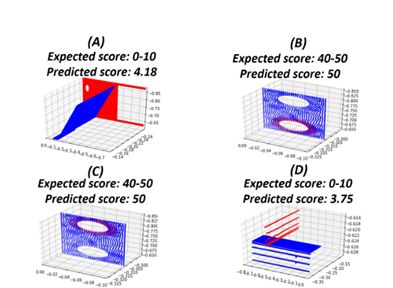

The ActivationNet algorithm computes a score ranging between 1 and 100 for every pair of 3D surface contacts in the product model. Surface-interaction models with a score of 90 or above can be trusted to deliver accurate simulation results, while interactions with scores below 20 can be safely deleted. Others that score between 20 and 90 should be reviewed or remodeled for complete confidence.

ActivationNet is a new capability that will help engineers improve their productivity in setting up contacts before running simulations, as well as significantly increase the accuracy of their ultimate results.

In initial testing, the ActivationNet algorithm has proven extremely accurate in assessing the quality of surface-contact modeling for a wide range of geometry shapes and sizes.

Improved Contact Modeling Is on the Horizon

As described in our recent paper, the Ansys software development team is currently running exhaustive tests to prove ActivationNet’s ability to assess and rate the quality of 3D surface-contact modeling for Ansys customers. The team’s research has confirmed that ActivationNet is learning true representations of interacting surfaces and performing better than existing deterministic algorithms at this sophisticated task. The results from ActivationNet have been shown to agree well with the expected results for various interacting surfaces with arbitrary shapes and sizes.

As ActivationNet continues to excel in these testing exercises, it may one day become a standard feature in Ansys mechanical and fluid solvers. The goal is to offer this proprietary, advanced software feature to help Ansys customers in every industry master the art and science of modeling 3D surface interactions ― a fundamental application that will help improve the simulation results and product confidence of the world’s development teams.

Read the full paper to learn how ActivationNet could change how engineers simulate 3D surface interactions amd learn more about AI and simulation here.