-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

Ansys Blog

October 19, 2020

One Airflow Simulation Can Save a Business

When the state of Oregon issued shutdown plans for nonessential businesses because of COVID-19 in the third week of March this year, John Huston, owner of Pacific Crest CrossFit Gym in Portland, was worried that the business might not survive the closure.

“It was terrifying, honestly,” he said. “I was afraid that everyone would put their memberships on hold.”

While the gym routinely deals with up to four holds at a time for vacations and other reasons, any extensive loss of membership fees from a large number of holds would put the gym in financial danger.

Huston soon learned that the business was more durable and flexible than he originally thought, due to something he already knew: CrossFit gym members don’t just come in for a workout and leave; they are a community who counted on working out together several times a week. He was soon to learn more about the range of expertise in this community in the next four months, as the business remained in lockdown.

Pacific Crest CrossFit Gym members worked

together to work out during the pandemic

First of all, the members responded well to his appeal not to put their memberships on hold. Second, physicians who were members of the gym stepped up to offer Huston advice on COVID-19 safety measures. As the gym moved their workouts outside, the physicians helped him to interpret the sometimes confusing and conflicting guidelines that were being issued by various medical groups and government entities. Third, a gym member named Andy Byers worked for Ansys and knew our fluid flow simulation software could model the flow of air in the gym, helping to ensure that members and staff would be safe when they reopened.

The Four Pillars of Reopening

By following the news and with the help of the CrossFit community, Huston established four pillars that had to be in place for reopening:

- Social distancing

- Hygiene

- Mask-wearing

- Ventilation

While there was plenty of guidance on the first three, ventilation was more of a challenge.

“Honestly, I didn’t even think about ventilation at first,” Huston says, until a member approached him and said she was concerned about being stuck in the back corner of the gym, with little airflow. The potential for air that was just exhaled from other people’s lungs — potentially an aerosol containing COVID-19 virus in droplets — had to be addressed.

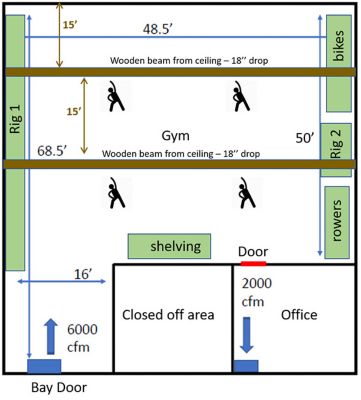

The gym's floorplan

Huston’s initial thought was to get a huge fan to move the air around. But his stepbrother, who works in commercial HVAC, said that would just blow the air around randomly and mix it up, not expel it. The answer, he said, was an overpressurization and exhaust model: overpressurize with good air and exhaust bad air. So, they obtained a 6,000 cubic feet per minute (cfm) fan and built a plywood blocker to seal the gym’s bay door. They also installed a 2,000 cfm exhaust fan in the front entrance area and sealed up that doorway.

Looking Through ‘Magic Glasses’

When Pacific Crest CrossFit opened after a four-month lockdown, Huston had all the pillars in place. Being unsure about the 6-ft social distancing rule, he divided the gym into 10 ft. by 12 ft. rectangles to give everyone more than enough space. The staff cleaned each area with a bleach solution when one member was finished and another needed to use that space. Everyone wore masks, and the ventilation system was up and running.

When Ansys employee Andy Byers, Strategic Partnership Director/Liaison, returned to the gym and saw everything that had been done, he looked at it through his Ansys-trained eyes.

“When you work for Ansys you have magic glasses that make you see all the lines of physics — I see airflows moving and electromagnetic waves coming off my phone,” Byers says, jokingly. The ventilation solution he saw wasn’t wrong, but because he is trained to always optimize a solution, he wondered if it could be made even better.

“Given the existing constraints and resources, can we tweak things and optimize the ventilation?” Byers wondered. “Knowing where the equipment and people are in the gym helps, because flow is complex and sometimes it behaves in ways that are not intuitive.”

Byers approached Huston and told him about his expertise: having knowledge about airflow simulation and access to Ansys’ design exploration software, Ansys Discovery.

“When Andy approached me about it, I thought: ‘Here’s just another shining example of a person in my community who has some expertise in a moment when we really need it,’” Huston says. “I feel really fortunate to have all these people with all these skills and knowledge bases so when it’s crunch time they are there for you.”

In the spirit of helping his community in a difficult time, Byers offered to run some airflow simulations at no charge to see if there were ways to optimize the ventilation system.

An Airflow Simulation Solution

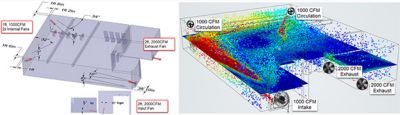

A model of the gym and simulation of its airflow

Byers asked Ethan Rabinowitz, Senior Applications Engineer at Ansys, to run the airflow simulations. He started by obtaining a layout of the gym, which is 48.5 ft. by 68.5 ft. by 12 ft. tall, with an 11-ft. wide bay door and a standard size office door. Fan A was 36 in. square and pulled in 6,000 cfm, while Fan B was 24 in. square and pushed out air at 2,000 cfm. Then he assessed the percentage of blockage to air flow caused by the rigs (0%), bikes and rowers (50%) and shelving (100%).

With these parameters set, Rabinowitz ran a series of computational fluid dynamics (CFD) simulations using Ansys Discovery, exploring various design variables in one-tenth the time of a single traditional analysis. This helped narrow down an optimum design configuration quickly, and then move forward with a more detailed analysis with Ansys Fluent.

From the resulting simulation output, Rabinowitz suggested that Huston alter the setup according to two modes:

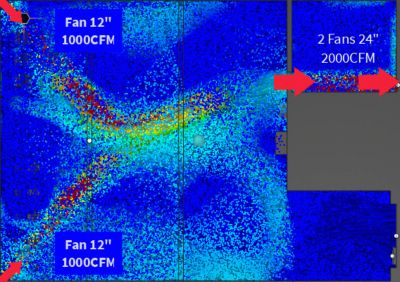

Mode 1: During the warm-up or weight lifting part of class (lower intensity, less breathing):

- Turn on 1,000 cfm corner fans and the outer 2,000 cfm fan

- This will naturally pull air in from bay door and push it out through office door at a lower rate that enables the instructor to be heard – i.e., not too noisy

Simulation of air flow in Mode 1

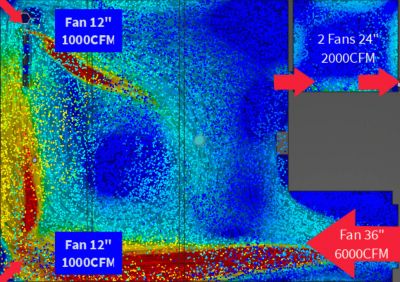

Mode 2: During the high-intensity part of class (workout of the day, or WOD) or between classes to clear out air:

- Turn on the 6,000 cfm input fan and two 2,000 cfm output fans. This will be noisier, but that’s acceptable for the WOD part of class.

- Turn off the corner fans. This is counterintuitive, but their angles counteract the natural circulation pattern that you want to establish during this phase.

Simulation of air flow in Mode 2. Note that the only “still” area is the

middle, but nobody is there so that is fine. All workout areas are

receiving a lot of replacement of air.

A Safer Workout During the Pandemic

Huston is currently working on implementing the changes suggested by Ansys. During the lockdown and throughout the pandemic, he has been driven by a two-part thought process. “We needed to follow the official guidance and regulations that were being issued,” he says, “and we had to make our members feel safe.”

Optimizing the gym’s airflow with Ansys engineering simulations was an extra step toward making the members feel secure that they were working out it in the safest possible environment during the pandemic.

Learn more in this recorded webinar: Simulation Saves Businesses: Exploring Unlimited Designs with Simulation.