-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

September 30, 2022

Delivering on Your Electronics Reliability Promises Just Got Easier

While today’s smart product designs offer expanded features and functionality, they’re also making the job of product development teams exponentially more challenging.

From cars and planes to medical equipment and consumer devices, it’s getting harder to verify and deliver reliable electronic performance. As more electronics are added to already-complex product systems, failure risks increase significantly — especially as more chips and printed circuit boards (PCBs) are squeezed into smaller and denser packages.

Electronics engineering teams not only need to assess the electromagnetic (EM) performance and structural integrity of their product systems, but also guard against thermal overstress, faulty solder joints, and other failure modes. They need to verify each individual component, as well as the multifaceted performance of the entire product system when exposed to real-world operating conditions.

What’s complicating this challenge? Just as they face historic shortages of engineering talent, product development teams are also being asked to increase their level of innovation and speed new products to market before competitors.

Smart Products Demand Smarter Ways of Working

The problem is that, while electronics product systems have taken quantum leaps forward, the project management processes and tool kits that engineering teams use to deliver these designs have remained virtually unchanged. Despite the complexities of having several functional teams apply multiple physics at both the component and system levels, product development teams are still relying on outdated practices and technologies to manage this process.

As more engineering disciplines and product development stakeholders get involved in system-level simulation and analysis, manual processes and project handoffs become problematic. Email exchanges and verbal conversations are also fraught with risk. Important deadlines might be missed. Key verification steps could be skipped. Results might be lost, resulting in rework. And, lacking a real-time view across functions, no one might actually know where projects stand.

And that’s just one part of the issue. There’s also the nearly impossible job of effective data management. System-level and multiphysics product simulations generate enormous volumes of data. Most engineering teams are using consumer-grade databases and tools, including Excel spreadsheets and Google Docs, to manage, store, and share that critical information. As a result, it’s scattered across functional siloes and usually hard to locate quickly.

The risks of these error-prone, inefficient ways of working are bigger than daily inefficiency, high development costs, and slow launch cycles. They include product recalls, warranty costs, lost customer loyalty, and irreversible damage to the brand reputation. Also at stake: meaningful innovation, which is stymied as critical projects sit stalled and unnoticed somewhere in the development queue.

Ansys Minerva: The Industry’s Purpose-built Solution

Fortunately, there’s a straightforward solution. Ansys Minerva is an enterprise-level simulation process and data management solution designed specifically to support highly collaborative, innovation-driven, interdisciplinary product development for complex systems including electronics. Backed by the proven performance of Ansys simulation software and based on 50 years of industry leadership, Minerva orchestrates and accelerates the development of advanced electronics.

Most electronics development teams are already leveraging the power of Ansys Sherlock to achieve fast, accurate, physics-based electronics reliability predictions at the component, board, and system levels. They’re likely using Ansys HFSS and Ansys SIwave to study and analyze EM performance, Ansys Icepak to conduct thermal analysis, and Ansys Mechanical to optimize structural and thermal properties. Minerva ties all these diverse activities into a single, cohesive workflow and brings cross-functional teams together on a unified platform.

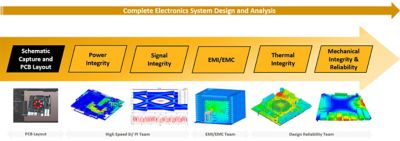

Figure 1. Analyzing the major challenges associated with electronics design

Ansys Minerva complements the robust capabilities of Sherlock and other Ansys solutions by providing development teams with:

- A central repository for all simulation and process data, creating a shared and secure real-time perspective across the entire interdisciplinary team. The value of data is maximized because it’s accessible to every team member on demand. It can be searched and re-used instead of starting every new simulation project from scratch.

- Process optimization and automation, as this purpose-built tool streamlines handoffs and enforces best project-management practices. Next steps, milestones, and project deadlines are visible to all stakeholders, driving transparency, ownership, and accountability. Scarce human resources are amplified via an increased level of efficiency and productivity.

- A basis for fact-based, data-driven decision-making, as all team members can view simulation results, weigh trade-offs, and make “good for the system” choices. Instead of having signal-integrity engineers focus solely on their own metrics, for instance, they can also look at the risk of overheating and other potential failure modes that might result from their design changes.

- Increased levels of collaboration and innovation that result from eliminating functional silos and encouraging cross-disciplinary design. In working with the world’s leading product development teams, Ansys experts have noticed a significant cultural shift toward increased collaboration as teams strive for rapid, seamless multiphysics analysis at the system level. Minerva is designed to facilitate that cultural shift.

- A single, robust technology ecosystem that addresses the everyday needs of product development teams. Of course, Minerva is designed for easy interoperability with Sherlock and other Ansys solutions — but it also integrates easily with any other tool, common databases, computer-aided design and engineering solutions, and product lifecycle management (PLM) systems. As an open platform, Minerva supports a cohesive, end-to-end simulation process across functional boundaries, engineering disciplines, and various third-party solutions.

Figure 2. Ansys Minerva’s intuitive user interface accurately captures all simulation data associated with a project.

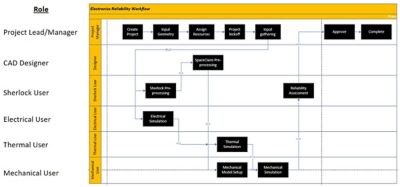

Figure 3. An organizational flow chart shows how Ansys Minerva is used for electronics reliability simulation projects.

Minerva offers another key advantage in this environment of talent shortages and budget cuts: it democratizes the use of Ansys simulation tools. Non-simulation specialists can easily master Minerva’s intuitive user interface and initiate lightweight simulation runs. This helps development projects advance fluidly and continuously, instead of waiting for scarce simulation experts to move them forward.

Still Not Convinced? Learn More at Level Up 3.0

Some of the world’s leading electronics product development teams are already using Minerva to eliminate blind spots, missed deadlines, lost data, redundant analysis, and design flaws that impact ultimate product reliability. Not only is Minerva helping them deliver more reliable designs and greater innovation, but it’s also cutting costs and accelerating launch dates through dramatic improvements in productivity and efficiency.

Ansys Level Up 3.0, scheduled for Tuesday, October 25, features a special session on optimizing electronics reliability via Minerva. Register now and get ready to bring the benefits of this unique simulation process and data management platform to your organization.