-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

February 20, 2024

Boost Your Simulations with Reduced-Order Models and Digital Twins

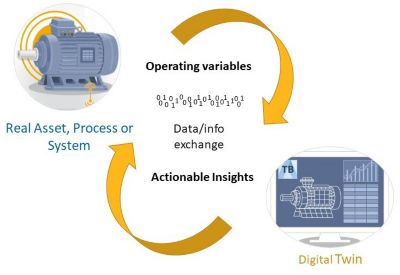

In the dynamic realm of engineering simulation, achieving efficiency and precision remains a constant challenge. Ansys Twin Builder offers a robust solution with its ability to create, deploy, and manage hybrid digital twins, which combine physics and data to mirror physical systems more accurately. However, the intricate demands of high-fidelity simulations often create computational hurdles, demanding extensive time and resources. This is where reduced-order models (ROMs) step in as a game-changing technique to redefine your approach to simulation and digital twins.

Essentially, ROMs are simplifications of complex models that capture the behavior of source models so engineers and designers can quickly study a system’s dominant effects using minimal computational resources. ROMs have become popular in the product development industry with market demands for shorter design cycles that produce higher quality products.

Twin Builder leverages ROMs to reduce computational burdens while retaining accuracy, enabling development and design teams to drastically accelerate innovation. Let’s explore the core concepts behind ROMs, their benefits, and how integrating Twin Builder and ROMs can optimize your workflow and products.

Streamline Accurate Modeling

Put simply, ROMs represent streamlined versions of intricate, high-fidelity models. These models distill the essence of their more complex counterparts, enabling engineers and designers to efficiently investigate a system’s primary characteristics while conserving computational resources.

The rising prominence of ROMs within the product development sector can be attributed to the escalating pressure on companies to meet market demands. These demands necessitate shorter design cycles while upholding the production of superior-quality products.

Twin Builder couples with Ansys’ multiphysics simulation to deliver the detail of 3D simulations as ROMs to generate accurate and efficient system-level models more quickly. For example, Twin Builder can use ROMs produced from Ansys’ structural, fluids, electromagnetics, and semiconductor products to model complex systems, including mechanical assemblies, electromagnetic actuators and machines, circuit and cable parasitics, thermal networks, and signal integrity.

ROMs can also be created in Ansys Workbench and easily imported into Twin Builder. Moreover, Twin Builder creates solver-agnostic ROMs. This means that ROMs can be created by any tool, including third-party tools, and then imported into Twin Builder as long as the training data has the required format. For Twin Builder, this requires that ROMs are imported or exported as functional mockup units (FMUs). FMUs use an open and tool-independent standard for model exchange between different simulation tools.

Co-simulation with 3D physics solvers preserves the full accuracy of finite element analysis (FEA) and computational fluid dynamics (CFD) for modeling fluid components and flow networks, rigid- and flexible-body mechanical assemblies, and electric machines and actuators. This enables you to shorten design and development cycles while maintaining accuracy and high-fidelity simulations, ensuring your products maintain top quality.

Designers and engineers can use Ansys Fluent to create a reduced-order model (ROM) by mapping out a response surface model.

Accelerate and Enhance Simulation

With the potential to speed up simulations — typically between 10 to 100 times faster — ROMs offer an invaluable resource for tasks such as design of experiments (DoE) and parameter sweep studies. Integrated seamlessly into Twin Builder, ROMs enable the generation of real-time applications, enhancing system responsiveness. Additionally, ROMs drastically minimize storage requirements and support the reuse of validated 3D physics models, further amplifying their influence in engineering and beyond.

A few of the top benefits of ROMs include their ability to increase efficiency, real-time predictions, and resource optimization as noted below.

- Efficiency: ROMs significantly reduce computational requirements, enabling faster simulations and real-time data analysis. This accelerates the development and deployment of digital twins, supporting quicker decision-making and problem-solving.

- Real-time predictions: ROMs provide the capability to make real-time physical predictions within a digital twin. This enhances the accuracy and responsiveness of the twin, making it a more reliable tool for monitoring and controlling physical systems.

- Resource optimization: By simplifying complex models while preserving accuracy, ROMs optimize the utilization of computational resources. This reduces costs and makes digital twin technology accessible to a wider range of applications and industries.

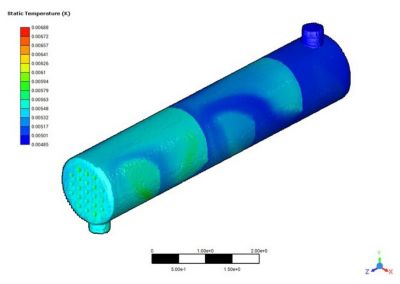

Ansys Fluent evaluates complex reduced-order models (ROMs) to explore design alternatives. For a cross flow heat exchanger, the ROM capability provides a solution for each design point in as little as a second, while a full simulation could take over two hours.

Put Digital Twins into Practice

Much like simulation itself, digital twins and ROMs benefit a wide range of industries, including automotive, aerospace, healthcare, industrial equipment, and many others. To demonstrate how Twin Builder and ROMs can positively influence workflows within these industries, let’s explore heat exchanger maintenance as an example.

Many industries use heat exchangers from food and beverage to refrigeration, pharmaceuticals, and chemical processing. However, the failure to predict and anticipate heat exchanger maintenance is a challenge that leads to equipment malfunction, delays, and other production nuisances

In this use case, Ansys provides a solution using Twin Builder, Ansys Fluent, and ROMs, by way of the following:

- Steady aerothermal Fluent model (with approximately 6 million cells).

- Static ROM (with 16 design points).

- Calcium carbonate thickness assessment in Fluent.

- Ability to export and deploy digital twin to an Internet of Things (IoT) platform.

Static ROMs are models that predict solutions using steady state simulation to determine the optimal design parameters and operating condition of a system. ROMs are generally trained from simulation data. A robust mesh of nearly 6 million cell elements helps ensure highly accurate results. In the same way, building a DoE with 16 design points encourages a thorough analysis of different input values and, in this example, each design point corresponds to a simulation that will be run in Fluent.

Digital twins enable predictive maintenance, enabling cost savings and the optimization of an asset’s operation.

Also, Fluent’s modeling capabilities enable you to accurately simulate multiphase flows including gas–liquid, liquid–liquid, gas–solid, particle flows, and even discrete element modeling (DEM). For this use case, the ability to model multiphase flows enables you to analyze and predict calcium carbonate thickness and potential buildup in the heat exchanger.

Further, by deploying digital twins with Twin Builder you can extend this insight with real-time monitoring. For example, when a digital twin is deployed to an IoT platform, it will receive inputs from the actual equipment through sensors. This enables the digital twin to predict performance, obtain the equipment’s current state, and any other task it was designed to do — in real time.

Ansys Twin Builder can easily connect with an Internet of Things (IoT) platform to send and receive operational data.

Adopt Digital Transformation More Easily

ROMs stand as an indispensable asset in the journey toward successful digitalization with their ability to support real-time physical predictions and equip your digital twin with accuracy. This not only streamlines complex processes but also provides the critical insights and efficiency needed to thrive in the digital age.

By harnessing the power of ROMs, you can drive innovation, enhance decision-making, and ultimately, lead the way in the evolving landscape of engineering and technology.

To learn more about how digital twins and ROMs can improve your workflow, watch the free on-demand webinar: Boost Simulation with Reduced-Order Models using Ansys Twin Builder.

To explore Twin Builder, request a free trial.