-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

August 19, 2019

Engineers Use Biomimicry to Innovate the Propulsion of Unmanned Underwater Vehicles

Unmanned underwater vehicle (UUV) designs haven’t changed much for the past few decades. Many UUVs still use traditional rotary screw propellers and torpedo-like hulls. Though dependable, this setup offers poor agility and payload capacity — making underwater operations, inspections, research and aquaculture costly and inefficient. Additionally, the noises these UUVs make can disturb the wildlife they are designed to observe.

NOA MARINE has designed a method of UUV locomotion, for commercial class vessels, that mimics the fins of a squid.

To keep costs down, the marine industry needs UUVs that can carry heavier payloads and travel longer distances. They will need to be sturdy, maneuverable, fast and rechargeable so they can handle long multiday missions without hitting obstacles — like fishing nets. Finally, these UUVs need to be silent.

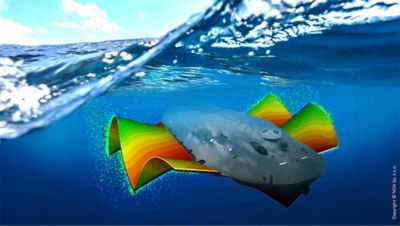

To reach those goals, NOA MARINE, an Ansys Startup Program member, performed biomimicry research to design a wave drive propulsion system that mimicked the propulsion of squid. Using Ansys Mechanical and Ansys Fluent, NOA MARINE showed that its UUVs and wave drive propulsion designs improve maneuverability, payload and acoustics.

Wave Drive Propulsion Solves Unmanned Underwater Vehicle Design Challenges

Many of the UUV design challenges can be solved by replacing the rotary screw with a new mode of thrust. For example, to achieve high efficiency, the rotary screw must rotate at a high speed. This generates a lot of noise, uses a lot of energy and creates cavitation that can damage the propulsion system.

By using a propulsion system with gentler motions, NOA MARINE can create UUVs that are quieter, efficient and able to carry larger payloads.

NOA MARINE’s UUV designs are much quieter than traditional screw propellers.

In fact, replacing UUV rotary screws has become a significant goal of the marine industry because they are now prohibited in protected environments. Therefore, companies that want to ensure their UUVs are still viable will need to buck with tradition and replace those screw propellers.

One efficient propulsion solution that engineers have been floating around the marine industry is to develop underwater gliders. However, this propulsion method does not provide the carrying capacity the market demands.

NOA MARINE’s wave drive propulsion system, however, mimics the way squid move under water. The wing-like fins on the side of the UUVs flap in a motion similar to a wave. This results in maneuverable, efficient, fast and silent propulsion that can carry payloads about 3 times larger than the industry average.

NOA MARINE used Fluent to build a virtual prototype of the UUV propulsion system. It also uses Mechanical to model the structural integrity of the UUV and its parts.

“We are using Fluent to simulate the complex, unsteady flow so we can optimize the thrust, shape and movement of the UUV fins. This lets us optimize the drone’s maneuverability, efficiency and gliding,” says Michał Ałaszkiewicz, CFD Engineer, at NOA MARINE.

NOA MARINE Tests its Unmanned Underwater Vehicles

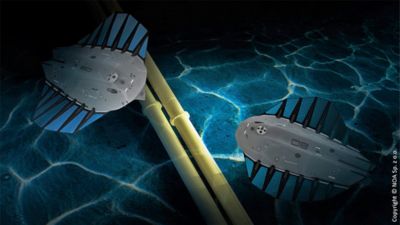

The squid-like UUV created by NOA MARINE will be tested in a survey of the Baltic Sea. During this time, NOA MARINE will be monitoring submarine ground water discharges (SGD) and seabed integrity. The study will also monitor the nutrient and pollutants within the water.

This monitoring mission requires the UUV to carry a lot of heavy, bulky sensors. As a result, it’s a perfect opportunity to test the lifting abilities of the wave drive propulsion system.

NOA MARINE’s UUV designs are inspecting a pipe.

Once proven, NOA MARINE plans to offer its UUV system through a robotics-as-a-service (RaaS) model that includes a satellite data link and solar recharging stations. RaaS operations require the use of a lot of sensors and digital twins for predictive maintenance to ensure that the product is operational and has optimal service protocols. Thanks to NOA MARINE’s wave drive propulsion system, its UUVs should have no problem carrying those sensors around.

To learn how other startups can follow in the wake of NOA MARINE and gain access to pervasive engineering simulation technology, read about the Ansys Startup Program.