-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

August 17, 2022

Ansys Electronics Reliability 2022 R2: Closing the Reliability Loop

For the second release of 2022, Ansys developers made a number of updates to the electronics reliability product portfolio, including improved efficiencies within our integrated multiphysics reliability workflows, key updates to the Ansys Sherlock Laminate and Package Manager databases, and optimized time-to-failure (TtF) predictions in Sherlock.

Let’s look at the major updates in this release, including how to download the latest version of our software and where to access the latest training resources.

What is Ansys Electronics Reliability?

Ansys electronics reliability solutions are a set of workflows that help structural, thermal, mechanical, electrical, and design engineers understand the influence of electrical, thermal, and mechanical effects on printed circuit boards (PCBs) and component designs. These effects include thermal cycling, shock and vibration, drop, static forces, solder fatigue, and others.

Using an integrated set of tools, engineers can determine how coupled multiphysics effects impact their board without having dedicated expertise or knowledge in finite element analysis (FEA) or computational fluid dynamics (CFD). By democratizing the simulation process, a single engineer can determine how the major causes of failure (such as solder fatigue) impact their PCB and make quick design changes to mitigate risks and reduce the number of physical prototypes and tests needed.

Learn how BMW uses Ansys Electronics Reliability solutions to assess the four major causes of electronics failure.

Ansys 2022 R2 Updates

Closed-loop Reliability Workflow

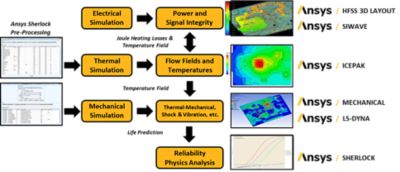

Major advancements have been made in this release to close the reliability loop between all our electronics reliability products, notably Ansys Icepak, Ansys LS-DYNA, Ansys Mechanical, and Sherlock. The cornerstone of the solution is Sherlock, which is the primary pre- and post-processing tool in our PCB reliability workflows.

In terms of pre-processing, users can build high-fidelity models within Sherlock that can be exported to Mechanical, LS-DYNA, or Icepak for analysis. The advantage of using Sherlock as a pre-processor is its vast parts library that contains more than 300,000 parts, which enables users to create higher-fidelity models for simulation. Additionally, in 2022 R2, there is now a link/export option between Ansys Granta Selector and Sherlock that enables users to pass data directly from Granta Selector to Sherlock. This enables improved access to electronics parts and materials, which ensures models are as close to physical reality as possible.

Finally, for this release, Ansys developers have closed the reliability loop between Sherlock, Mechanical, Icepak, and LS-DYNA, allowing analyses to be sent back into Sherlock for post-processing. Sherlock is a reliability prediction tool that provides TtF predictions for each component on the board, enabling users to understand how thermal and mechanical effects will impact overall lifetime. This new closed-loop workflow enables comprehensive insights into how coupled multiphysics impact the life cycle of PCBs and its components.

Figure 1. Closed-loop workflow utilizing Ansys Sherlock as the main pre- and post-processor and Ansys HFSS, Ansys SIwave, Ansys Mechanical, Ansys LS-DYNA and Ansys Icepak for running various analysis types.

Improved Time-to-Failure Accuracy

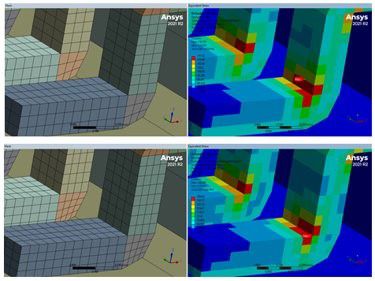

Sherlock’s TtF predictions provide valuable insights and are represented through a reliability table and graph that indicate if a component meets or fails to meet desired lifetime goals. For this release, our developers have made substantial improvements to Sherlock’s TtF calculations, including implementing a methodology to handle sharp corners to improve the reliability predictions of leaded devices.

Figure 2. Lead singularities

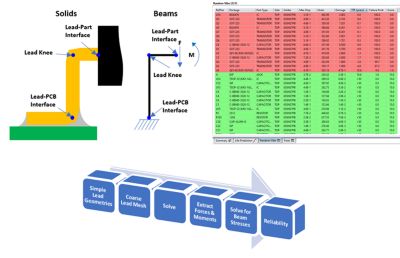

Leads often have sharp corners, which can lead to stress and strain singularities. These singularities can often impact reliability predictions and provide results that are too conservative. With the updated analytical beam approach in this release, Sherlock software assumes the lead is fixed at its connection points and solves stresses along the lead using beam equations (using force and moment data from the underlying simulations). The advantages of this process include results that are less sensitive to mesh and in which lead singularities are eliminated, leading to lower computational costs and TtF predictions that are more advanced and accurate. Further, a number of different lead types are supported in this new framework, including L-shaped cantilevers (gull wings, J-leads, C-leads, and structural insulated panels, or SIPs), simple cantilever beams (L-leads, through holes), angled cantilever beams (bent SIPs), and axial-180 cantilever beams.

Figure 3. Analytical beam approach for reliability assessments of leaded devices

Laminate Database and Package Manager Enhancements

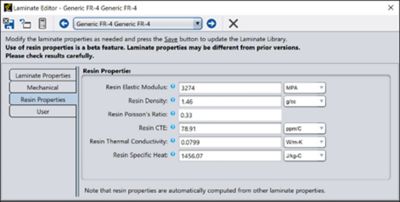

New improvements to several key databases within Sherlock enable improved calculations of laminate properties and more flexibility in working with packages.

Improvements to the Laminate Database in Sherlock facilitate enhanced resin property calculations in the Stack-up Editor when Glass Style is specified. This new approach helps provide more realistic mechanical properties for laminates. This capability is currently available as a beta feature so users can become more familiar with the functionality before it is set as the default.

Figure 4. Laminate Editor updates in Ansys Sherlock 2022 R2

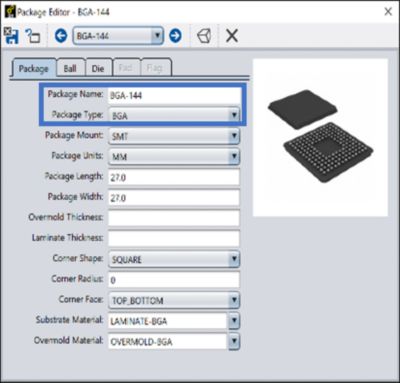

Further, in 2022 R2, the Sherlock Package Manager has been updated to allow users to enter a package name directly in a text-editable field. Additionally, a new property — “Package Type” — allows users to select which package type they wish to be associated with the indicated package. This is important for users who would like more control in their modeling and reliability predictions.

Figure 5. Package Manager updates in Sherlock 2022 R2

How Do I Access the Latest Version of the Software?

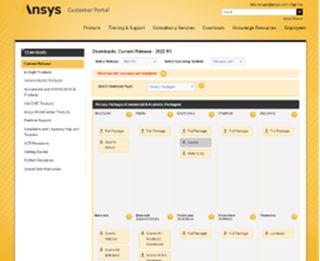

You can download the latest versions of all Electronics Reliability product software (Sherlock, Mechanical, LS-DYNA, and Icepak) at the Ansys Customer Portal (registration required). Sherlock, Mechanical, and LS-DYNA are included in the Structures package, while Ansys Icepak can be accessed by first installing the Fluids and Electronics packages.

Figure 6. Navigate to the Ansys Customer Portal to download the latest version of the software.