-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

June 1, 2022

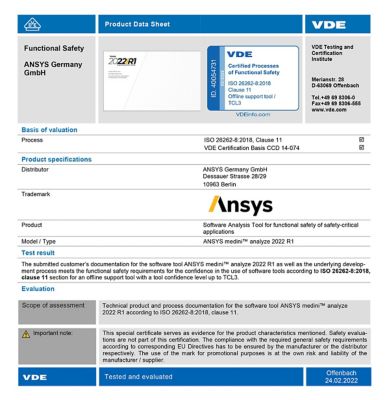

Ansys Delivers ISO 26262 Certified Tool Sets

Considering the cost of electric and autonomous vehicle (EV/AV) development, most automotive manufacturers along the EV/AV supply chain require proof of ISO 26262 compliance before they do business with anyone. General Motors, Ford, and Audi are deeply committed these technologies to the tune of almost $72 billion dollars through 2025. It’s a big investment, which is a big reason why automotive manufacturers are deeply focused on ISO certification.

Ansys has some exciting news about our tools regarding quality and safety verification of future automotive innovations. Our product portfolio is now ISO 26262 safety certified to help build sophisticated system electronics related to AV and EV technologies. Read on for some background on this ISO standard, and how Ansys is building confidence in the automotive community with dynamic tools that bring a high level of certainty to AV and EV electronics safety analysis.

Greater Certainty and Reliability in Electronics with Certified Tools

Until now, successful ISO 26262 development and analysis depended on a patchwork of dedicated tools coming together, each assigned to a specific aspect of the safety process. Ansys medini analyze ISO 26262-certified analysis software for automotive electrical and electronics applications enables safety analysis in one comprehensive solution. It offers transparency in safety design and development, which builds trust and inspires collaboration among original equipment manufacturers (OEMs), suppliers, and other key decision makers to bring AV and EV technologies to market faster.

“Ansys medini analyze presents a holistic solution to support the automotive safety engineer tasked with a thorough analysis of the complete electronics life cycle at various stages of development,” says Dr. Michael Soden, a lead product manager at Ansys. “The tool enables essential analysis of a long list of tasks executed from the early stages at the OEM down to the final component, from hazard analysis and risk assessment to detailed failure mode analysis and reliability predictions. Factoring in the recent ISO 26262 certification of our tool development process introduces a higher level of certainty into our product.”

The Gold Standard for Functional Safety

ISO 26262 is an internationally recognized standard for functional safety of electrical or electronic vehicle systems issued by the International Organization for Standards (ISO), an independent, global organization headquartered in Geneva, Switzerland, representing 167 international standards bodies. ISO sets the bar for quality and efficiency for products, services, and systems with consensus-based, market-relevant standards. These standards are driven by a need in the market for quality and transparency, inspiring tremendous trust among manufacturers and government bodies.

This standard is not a formal regulation — rather, ISO 26262 defines the state of the art for safety activities related to the design and development of vehicle electronics and electrical systems. It establishes faith among all key stakeholders that innovations in vehicle technology will match the same high degree of safety integrity, resulting in trusted products that are safe enough for the road ahead.

How Does ISO Certification Work, Exactly?

During the certification process, independent assessors review the work products Ansys creates during design and development of a tool, such as the specifications, design documents, or test cases they write, as well as the reviews they perform. ISO assessors do not interact with the tool directly; instead, they examine the process of how the tool was produced. Certification involves those activities performed to check whether Ansys’ process is fit for the purpose of safety tool development and can be followed in a daily team workflow. Whatever Ansys specifies its tools to compute it should be able to achieve and implement correctly.

A Model-Based Approach to Safety System Design

Ansys medini analyze isn’t just a point tool supporting individual methods in isolation, but an all-embracing tool set that combines every relevant method in one chain working within the notion of models. The design is expressed first by the engineers involved, then all the analysis is connected to the design for an integrated approach to model-based systems engineering (MBSE), testing, and analysis.

If you’re a safety engineer, for example, you can import a high-level system design model directly into medini analyze without having to recreate at least the basic functions or structures of your design to get started. With the press of a button, you can generate a failure mode and effects analysis (FMEA) table, enabling you to identify failures and their causes quickly and easily while keeping up with countless iterative design changes. The ability to directly connect safety requirements to the design adds up to a big time savings for engineers during product development.

Ansys SCADE and medini analyze: A Winning Combination with ISO 26262 Certification

Another aspect of EV/AV functional safety related to electronic components is the embedded software that monitors, manages, and controls electronics. A single flaw in software code has the potential to endanger the safety of all vehicle occupants. Ansys SCADE offers a model-based design environment, coupled with an automatic code generator, as an alternative to manual development, testing, and verification of embedded software code. Using this ISO 26262-certified set of tools, engineers spend less time developing and testing to achieve greater accuracy in code verification of critical embedded systems software.

Together, medini analyze and SCADE support a seamless, model-based approach to automotive system development. Essentially, medini analyze provides all required system safety analysis for an ISO 26262 system, while SCADE provides the embedded software piece of the system. Both tools are connected consistently via a model-based approach, which increases product consistency and quality and reduces effort for engineers.

Interested in automating your ISO 26262 certification process? Ansys offers free trials of medini analyze and SCADE to help you get started.