-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

May 2, 2019

Ansys' Acquisition of DfR Solutions Will Help Ensure the Reliability of Electronic Systems and Components

In today’s world, we are surrounded more and more by electrical components. As consumers we demand electronics that are smaller, last longer, and can withstand a variety of conditions that typically wreak havoc on electrical components (drops, heat/cold, moisture). Currently, electronics reliability analysis is often skipped or performed late in the product design process.

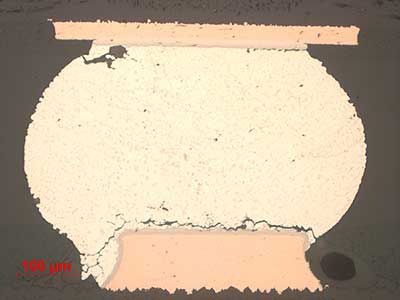

Solder crack on electronics PCB board

This is where the folks at DfR Solutions come in by leveraging their industry-leading expertise in electronics reliability and physics of failure via the Sherlock Automated Design Analysis™ software. Sherlock moves electronics reliability analysis earlier in the design process – saving time and money – by making this analysis accessible to designers.

Sherlock offers a unique, fully-validated, turnkey solution for analyzing the physics of failure for a wide variety of electronics systems and components. Using independently validated algorithms, engineers can subject their products to virtual constant temperature, thermal cycling, power-temperature cycling, thermal shock, random vibration, harmonic vibration, mechanical shock, and flexure to help ensure manufacturability and maximize product lifespan – reducing development time and cost.

An Engineer’s Dream

The engineers at DfR aren’t just a bunch of developers drawing from published articles and academic research. The team has extensive hands-on experience with electronics reliability physics testing in addition to an experienced service staff and state-of-the-art, on-site physical testing capabilities, including a scanning electron microscope, drop test, thermal chambers, and digital image correlation (DIC). Seeing the computational simulation and physical testing working together is an engineer’s dream. This physical testing experience and expertise has been critical in the development of the world-class electronics reliability functionality found inside Sherlock.

On-site testing lab at DfR office

How DfR’s Technology Will Expand the Ansys Experience

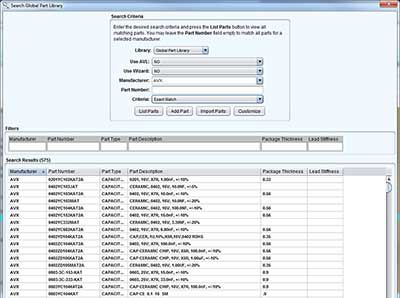

Sherlock’s complete reliability and automated workflow solution is comprised of three phases. In the first phase, quick and complete data is input from the electronics designer package (ECAD/EDA). This includes parsing of EDA files and leveraging a huge internal embedded parts library comprising over 300,000 components (part, package, materials, solder, laminate) to quickly generate an FEA model.

Sherlock embedded parts library

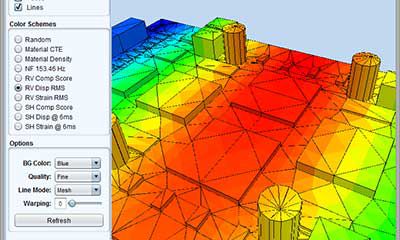

In the second phase, Sherlock sets up and performs a variety of analyses including thermal cycling, mechanical shock, random vibration, and thermal derating. Sherlock already closely integrates with Ansys software as well as other CAE tools to perform these analyses. In the third phase, a concise and insightful automated report that includes results and recommended actions is created.

Together, Ansys and DfRSolutions are positioned to provide a complete solution for electronics designers and analysts in this quickly expanding market of electronics reliability.

Learn More

For more information, see the press release: “Ansys Acquires Assets of Electronics Automated Design Analysis Lead DfR Solutions.”