-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS BLOG

October 6, 2017

Hey You, What's that Sound?

I’m one of those people who get wound up by the sound of a rattle of the smallest type. Noise and vibration are more than just a bug bear though — or pet peeve depending on your geography — and simulation of acoustics is something can have a big impact on more than just the easily agitated (like me).

Systems that generate (undesired) noise are not efficient, some of the energy they use goes into making the sound.

A prime example would be a motor-driven gear train. The whine that motors emit and the noise from the attached gearbox could be a major source of noise in an otherwise quiet system. It is also a sign that things aren’t as they should be.

Simulation can play a key role here in predicting the noise level of the whole powertrain. It’s not a simple problem to solve but there are ways to make it very manageable.

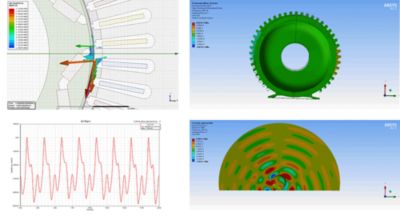

There are several possible contributory elements to the noise from our example system. The first is the motor itself. The animation below shows how the forces within the motor vary. As the stator and rotor rotate the forces between them rise and fall.

This varying force could be a possible source of resonance, or ringing, in the motor housing. There could of course be other things going on in the motor too. Any slight variance in manufacturing could cause an imbalance. This is also true of the gearbox.

The ideal gearbox has no imperfections and all the teeth, bearings and shafts are completely rigid. The reality is though that everything bends a little and that gear teeth will have some (admittedly small) imperfections.

Lastly there is also the consideration of the dynamics of the system. Rotating components have the potential to vibrate due to their own inherent instabilities. Everything could be perfectly made to exacting measurements but still vibrate.

So we have, in our simple example, three distinct possible sources of noise. The varying forces in the motor, the imperfections of the gearbox and the dynamic effects of spinning components.

These are all challenging aspects in their own right to try and understand. Coupled together they become a real challenge. We recently released the ability to directly carry out acoustic analysis in Ansys Mechanical. Excitations from Maxwell (or any other source) can be brought into the analysis. This means that you can start to build up a thorough understanding of the noise within your system.

I’m hopeful that annoying rattles and whines will one day be a thing of the past!

Think it sounds interesting? Learn more about simulating acoustics with Ansys Mechanical.