-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

ANSYS ADVANTAGE MAGAZINE

May 2022

Additive manufacturing (AM) has made it possible to manufacture products with complex shapes that could not be manufactured using traditional methods, such as casting, molding, forging, or machining. By precisely depositing layers of powders (metals or polymers) and thermally fusing the powder particles of each layer to themselves and to subsequent layers, there is almost no limit to the geometries of real-world working parts that can be produced. From small heat sinks that are optimized for efficiency to enormous rocket engines that will launch future astronauts into space., AM can do it all.

What AM couldn’t do until now is produce these parts as quickly and consistently as manufacturers would like. Additive manufacturing typically requires numerous rounds of trial and error to optimize a new additively manufactured part. Even when the design and AM process have been finalized, other variables can be introduced into the process — such as a new batch of material or different environmental conditions — that can affect repeatability. Considering the high cost of metal powders that are wasted in a failed build, additive manufacturers cannot afford failures.

The Challenges of Additive Manufacturing

The key challenges for large-scale adoption of AM in industry are speed and reliability. How can you rapidly optimize process parameters for additively manufactured parts, thus reducing time to market? Overcoming these challenges is made even more difficult because every AM process has its own set of process parameters, including material properties, manufacturing settings, and changing environmental conditions.

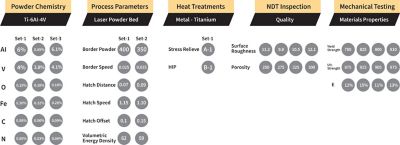

Even just focusing on material properties can result in a large number of variables. The powder chemistry of an alloy can vary widely because of small levels of impurities that can change the composition of every batch. What percentage of variance in the concentration of titanium in a Ti-6Al-4V alloy powder can be tolerated before an AM build fails? How do levels of impurities such as oxygen, iron, carbon, and nitrogen affect the tensile strength of the resulting AM part?

Possible variations in processing parameters in a laser-powered AM machine (border power, border speed, hatch distance, hatch speed, hatch offset, volumetric energy density, etc.) add to the complexity of the AM challenge. Add in heat treatments, non-destructive testing (NDT) inspection, and mechanical testing variables, and soon you have a major data management challenge on your hands.

You may also encounter challenges in predicting cause-effect results when one or more variables change during the build process. Being able to predict what will happen plays a large role in ensuring a high rate of build success when so many process-property combinations exist.

A representation of the sheer number of AM variables.

Using machine learning to identify the causal links between AM data.

A Data-Driven Approach to Handling AM Data

The first step to confidence in the AM process is helping engineers capture and manage their materials information. That’s the primary focus of Ansys Granta MI. It enables companies to collect, organize, and store their own materials data gathered from testing of incoming raw materials and outgoing end products. This customized data is invaluable in fine-tuning the AM process for a company’s proprietary materials intellectual property. Granta MI also gives companies a single repository for materials information — a “single source of truth”— which avoids the problem of different engineers working with different data.

Even with the data management capabilities of Granta MI, real-world AM datasets are typically sparse and noisy — “sparse” meaning that there are gaps in certain lines or columns of a dataset, and “noisy” meaning that there can be a large spread between different measurements of the same property. Another problem is that even though there may be gaps in the data, these material datasets can become too large to efficiently extract useful data.

Ansys 2022 R1 machine learning for additive manufacturing data.

So, Ansys partnered with Intellegens to incorporate its Alchemite™ algorithm to statistically fill in the gaps and reduce the noise in the data. Machine learning (ML) algorithms, often based on neural network approaches, build models from sample data, known as the training data. Based only on what they have “learned” from this data without further explicit programming, these models support tasks including:

- Predicting missing values in the rest of the dataset

- Predicting outputs for a new set of input variables

- Optimizing performance by predicting which inputs will best achieve desired outputs

- Identifying outliers, anomalies, or clusters in the data

- Identifying which inputs are strong drivers of which outputs

Machine learning uses existing AM project data to build predictive models that identify key process-property relationships, guide your testing program, and propose optimal processing parameters. In short, Alchemite can extract value from your data even when it is sparse, noisy, and in high volumes. When you have too little data, ML helps you focus your data acquisition efforts efficiently by identifying key parameters that are missing. When you have too much data, Alchemite can extract the key parameters that are critical to predicting AM build success. Learn more about how the Ansys solution works for AM data with our white paper: How Machine Learning Helps Getting Additive Manufactured Parts to Market Faster.

Using Machine Learning to Identify the Casual Links Between AM Data

This new level of insight into AM data enables engineers to control the AM process and optimize material and part performance. You can achieve results with a greatly reduced number of experimental test cycles, which helps accelerate time to market and leads to substantial end-to-end total cost savings for AM programs.

Solution in Three Apps

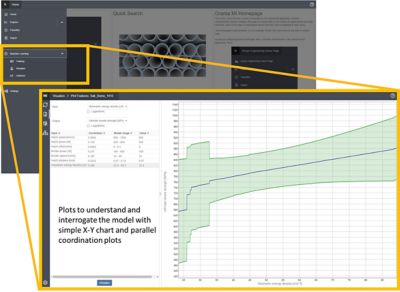

To make the software easy to learn and use, Granta MI for AM solutions has been distilled into three apps: a training dataset app, an optimization app, and a visualization app.

- The training dataset app helps engineers create the training dataset for the neural network. With just a few clicks, you can extract key data from the Granta MI database to form a complex feature matrix that can be used to train the neural network.

- Using the optimization app, you can take the model created by the neural network and interrogate it to get answers to your specific questions regarding AM processes. Questions such as “How can I maximize a certain property?” or “How can I reduce a specific failure mode in my build?” can be answered by this app.

- Finally, the visualization app lets you quickly understand your data. A graph can be much easier to understand than a complex table of data points. In the visualization app, engineers can take a slice of a complex dataset and have it displayed graphically to generate insights from the data.

Bright Outlook for Machine Learning in Additive Manufacturing

Almost 60% of 375 businesses surveyed by MIT Technology Review in 2016 were incorporating ML into their operations. A report by the leading marketing research firm PwC notes that 100% of companies identified as “digital champions” (as opposed to “digital novices”) are planning to use ML by 2025.

They have good reasons for doing so. According to Ansys’ calculations, AM processes that combine a data management system with ML are predicted to result in a 50-90% reduction in the number of experiments needed to establish the correct AM processing parameters. This and other benefits will lead to a 10% cost reduction in the global AM market. Learn more from the Ansys white paper “How Machine Learning Helps Getting Additive Manufactured Parts to Market Faster.”

For AM to continue growing as an industrial manufacturing process, manufacturers will have to rely on improvements that reduce the number of build failures and give them confidence in their workflows. They can’t afford to keep wasting money on expensive metal powders that only end up on the scrap pile. Ansys will continue to add features to Granta MI and work with Intellegens to make ML an even more important part of the AM build process, ensuring that the benefits of additive manufacturing will be available to future generations of engineers.

If you would like to see how this can work for your company, book a demonstration with our team.

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.