-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

November 18, 2022

NI and Ansys Launch Joint Solutions for Customers in Aerospace and Beyond

One thing Ansys and NI customers have in common is a shared desire for accuracy. Whether a group of designers creates models using a tool from Ansys’ vast simulation portfolio, or a group of engineers authenticate those models using NI’s validation software and hardware, accuracy in design is a common objective.

While these groups can work independently and still achieve results, how much more successful would design and development be if they connected their approaches using joint solutions?

This potential has been the driving force behind the NI and Ansys partnership. The success of such technology pairing has already been seen in the automotive space with hardware-in-the-loop (HIL) solutions for cameras in advanced driver assistance systems (ADAS) and autonomous vehicles (AV). But most recently, the companies are off-roading onto new terrain by integrating NI tools with Ansys Systems Tool Kit (STK) digital mission engineering software to deliver solutions for the aerospace industry and beyond, with customer needs at the heart of the collaboration.

Better Results and Validation for Customers

In its more-than-40-year history, NI continues to produce modular hardware, software, services, and systems that set the standard for validation through automated test equipment and measurement systems. This year, NI demonstrated one of its latest developments, a satellite link emulator (SLE), at the Farnborough International Air Show. The standout element of the SLE is its connection with STK, which provides a physics-based modeling environment for analyzing platforms and payloads in a realistic mission context.

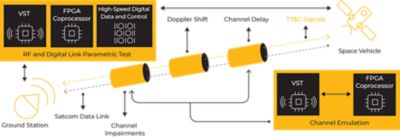

To develop the SLE, which has the potential to validate next-generation satellite communication links, NI uses a HIL approach by connecting NI’s PXI hardware and LabVIEW field-programmable gate array (FPGA) technology into the STK platform. This combination enables communication links between satellite and ground stations to be validated against accurate and realistic channel parameters in real time by simulating within a digital mission engineering environment.

NI PXI systems provide high-performance modular instruments and other input/output (I/O) modules that feature specialized synchronization and key software features for testing and measurement applications, from device validation to automated production tests.

“Our tools – NI and Ansys - can work individually just fine, but the pace at which our customers are being asked to innovate and the complexity of the systems they’re trying to develop is prompting us to ask, ‘What are the connections that we could make between our tools that would make that workflow more seamless, more real-time, or more iterative?’” says Luke Schreier, Senior Vice President and General Manager of Aerospace, Defense, and Government Business at NI. “How can we reduce the ‘throwing it over the wall’ effect and failure to “close the loop” with real data from real-world experiments that feed back into the simulation?”

The SLE is just one instantiation of this HIL concept to “close the loop” with real data, demonstrated within an electromagnetic (EM) environment with the connection between a satellite and ground station. However, HIL concepts can be expanded to other communication links such as 5G, other terrestrial networks, or even other systems that interact using EM energy.

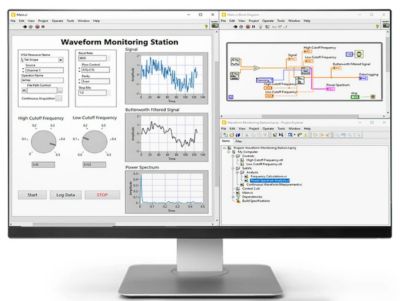

LabVIEW is a graphical programming environment developed by NI, which engineers use to develop automated research, validation, and production test systems.

“What we’ve done as a partnership most recently is focus on mission critical applications around communications and satellites,” says Chris Behnke, Chief Offering Manager of Radar, Electronic Warfare, and Communications at NI. “We’ve interfaced the STK software, which provides the accurate simulation to our real-time hardware platform, and that allows us to validate the hardware under the same conditions that the simulation was run. Subsequently, it allows us to update that simulation with real measured data. It’s a synergistic cycle where we can inform the system-under-test with the simulation, and then further inform the simulation based on the results of the testing itself.”

This collaborative approach provides customers with more insight to better inform their designs and missions in real time, which reduces error, time needed for development, material and operational costs for the project, and, most importantly, risk. Consequently, the value of the partnership for both Ansys and NI customers exceeds monetary value and results in richer, higher-fidelity simulations that ensure the safety and success of products and missions.

Digital Mission Engineering, Modeling in Motion

STK expands upon standard simulation tools by applying simulation in a mission-planning setting. Though other simulation tools can achieve results, such static, one-off models often lead to disconnected solutions that need to be pieced together or compared later. Alternatively, STK provides a 3D, multidomain platform that is equipped for larger system-level projects and supports various engineering disciplines within one application. This enables customers to see how critical engineering dynamics affect each other in a real-time environment. This insight can inform your designs — and the validation of those designs — more comprehensively, speedily, and accurately both in unison and in motion.

“A satellite, for example, can travel 17,000 miles per hour in space, so it’s moving fast and the ability to model the motion of the platform, the kinematic effects, and the radio frequency (RF) environment effects all have an impact on the effectiveness of the mission,” says Shashank Narayan, Senior Director of Research and Development in Digital Mission Engineering at Ansys. “Also, as platforms move, relationships with other platforms change, and the ability for a satellite to surveil a certain area depends on where it is in orbit. Understanding these dynamics is critical, and with the help of design reference missions (DRMs) using STK, you can model these scenarios and then test against the DRM using NI tools.”

Image illustrates the connection between Ansys STK and NI solutions, where STK provides the platform motions, kinematics, payload models, and other environmental impacts that contribute to forming a realistic simulated radiofrequency (RF) link. This provides an executable simulation loop where engineers can design and test their RF systems through both software-in-the-loop (SIL) and hardware-in-the-loop (HIL) strategies.

DRMs are not a new concept and can be traced back to early Apollo missions. Essentially, a DRM enables systems thinking, automation, and fact-based decision-making across a product’s life cycle to ensure the safety and success of a mission. In simplest terms, it helps design or prepare a “reference,” or plan.

Key features of STK that equip it for such mission planning include communications, radar, and electro-optical and infrared (EOIR) modeling. With the communications capability, you can model all the physical components of a system, including the RF environment. Similarly, the radar capability enables you to model system performance in synthetic aperture radar (SAR) or search and track modes. This means you can model monostatic, bistatic, and multifunction radars in the context of your mission to account for the participation of every asset. The EOIR capabilities expand upon this further by enabling teams to model EOIR detection, tracking, and imaging performance, which support the product throughout its entire life cycle, including concept development, design, field testing, and operations.

“The simulation is only as good as the data you put into the model — so from our perspective, the STK software provides an accurate first simulation, and then our platform gives the ability to measure the physical input and output (I/O) points or the physical hardware as it actually operates, which gives you a next level of detail that you can then circle back to your design,” says Behnke. “The real-time nature really comes into play when the hardware and software solutions can run in parallel. As the simulation is running, you can look at your simulation results and your real-time hardware results in unison and in sync to see both sides of the coin.”

One misconception of digital mission engineering is that it is synonymous with model-based systems engineering (MBSE), but while the two have similarities, there is one major difference. Though MBSE applies modeling to support system-level engineering and encourages the use of models through development and later phases of a project, this type of modeling does not adapt in real time or in a continuous manner.

Alternatively, digital mission engineering can be viewed as a digital thread of MBSE, aiming to deliver a continuum of modeling that changes and grows throughout the product life cycle.

“One of the most important outcomes of digital mission engineering is to create mission models that capture mission objectives by modeling the actual platforms and their payloads, but also the operational environment in motion and real time,” says Narayan. “Therefore, models that are created at the beginning of the life cycle need to be persisted, exchanged, and grown in terms of fidelity and sophistication throughout the life cycle. From that perspective, we see digital mission engineering as a critical digital thread that expands upon and enhances classic MBSE and its value.”

Upcoming Missions Made Possible

Many of NI’s validation solutions are based on the premise of merging test instrumentation with digital signal processing (DSP), which allows customers to emulate parts of the system that may not be designed yet, or perhaps the ecosystem for which the asset is being designed. By implementing validation into a mission-planning platform, not only is predictive foresight strengthened surrounding these known variables, but the potential to visualize unprecedented scenarios that have unknown variables can also be realized.

“Simulation environments like STK almost inherently propose different combinations of I/O that a normal validation process might not explore, and that’s where the merger of the two tools and approaches is really beneficial for the customer,” says Schreier. “But making these connections is more than just the sum or connection of two different tools. It is potentially unlocking innovation or accuracy that wasn’t even possible before.”

To learn more about NI’s solutions for aerospace applications, visit their site here. To explore Ansys STK, request a free trial or learn more here.