-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

November 16, 2022

MBSE Enhances the Safety and Cybersecurity of Autonomous Vehicles

The continuing enhancement of automobiles with advanced driver assist systems (ADAS) and the ongoing quest to produce fully autonomous vehicles (AVs) that communicate with each other on the road leads to larger, more complex systems. Simultaneously, it demands more safety and security in automobile systems design. But safety and security requirements can sometimes clash. To make a car safer requires additional components to monitor the operation of the vehicle, but these components may make the vehicle less cyber-secure by offering new entry points for hackers to access the control system and software.

To support development of such large, complex systems and provide a robust development framework for automotive system designs, Hitachi Industry & Control Solutions, Ltd. (Hitachi Industry & Control Solutions) of Japan established a specialized department called the MBSE Design Lab in 2019. It expanded to become the MBSE Design Center in October 2022. This model-based systems engineering (MBSE) Design Center features Ansys SCADE embedded software and Ansys medini analyze functional safety and cybersecurity simulation software as key elements of their approach to designing safe and secure automobiles.

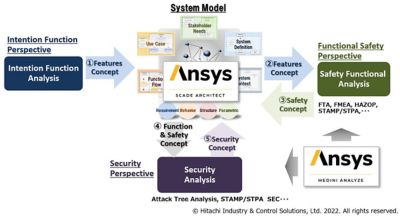

Through the MBSE Design Center, Hitachi Industry & Control Solutions is practicing strategies to manage functional safety and cybersecurity when supporting automotive OEMs and tier-one suppliers in their design and development of automated driving, automotive infotainment, and automotive control systems. From the functional perspective, Ansys SCADE Architect is used to design architecture through step-by-step detailing. Ansys medini analyze makes it possible to run two types of analyses — safety and security — on one common model.

“We believe that the integration of Ansys simulation tools and MBSE gives us visibility into the entire design process, reducing development costs, improving engineering efficiency, driving innovation, and designing competitive products,” says Takeo Hashimoto, General Manager of MBSE Design Center, Hitachi Industry & Control Solutions.

Flowchart for managing functional safety and cybersecurity of automobiles using Ansys solutions at Hitachi Industry & Control Solutions

Inventing an MBSE Solution

Hitachi Industry & Control Solutions has transformed their development style from traditional design to systems engineering to MBSE over the last 10 years. Before that time, developments in the automotive field started becoming increasingly large and complex, leading to problems at their customers’ automobile development sites.

“The development sites were experiencing a lot of rework in the verification process, which could no longer be handled by conventional development methods,” Hashimoto says. “We spent a lot of time studying how we should organize the requirements while effectively using existing assets to address the issue of insufficient documentation in the upstream process, which is the basis of the verification process.”

This detailed study led them to the conclusion that systems engineering was the solution to their problems. As defined by INCOSE (International Council on Systems Engineering), systems engineering is “a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods. In particular, it focuses on establishing, balancing and integrating stakeholders’ goals, purpose, and success criteria, and defining actual or anticipated customer needs, operational concept, and required functionality, starting early in the development cycle.”

“But, at the time, there was very little literature on systems engineering in Japan,” Hashimoto says. ”We have been taught by pioneering universities in Japan and gradually developed it through repeated trial and error based on overseas literature and information from INCOSE. We were the pioneers of systems engineering practices in Japan.”

Even with systems engineering in place, when it came time to proceed with the upstream process of requirements analysis and architecture design, the design information became too voluminous, and the traditional paper-based development style of systems engineering faced new challenges that made it difficult to develop and manage while maintaining overall consistency and integrity.

Soon, Hitachi Industry & Control Solutions was transforming to MBSE, which INCOSE defines as “the formalized application of modeling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.”

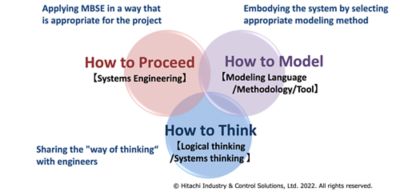

In effect, by introducing MBSE — utilizing a system model that expresses the relationship between the multifaceted requirements and functions of the system — it has become possible to achieve a common understanding with stakeholders, including engineers, and to develop and manage large-scale and complex systems while maintaining overall consistency and integrity.

The three axes of MBSE at Hitachi Industry & Control Solutions

Inserting Simulation into the MBSE Process

MBSE makes it easy to analyze and simulate frequently in the early stages of the product development process to confirm requirements and begin reviewing design alternatives before spending money on prototypes that ultimately fail to meet requirements.

The engineering teams at Hitachi Industry & Control Solutions spent some time in determining how best to integrate Ansys simulation solutions into the product development process. Without this integration, requirements could not be validated and performance, cost, and risk tradeoffs could not be fully evaluated.

As mentioned earlier, in safety design it is standard practice to design external components to monitor for component failures. This is to ensure that anomalies caused by component failures are detected. However, in security design, this external component can also create a security risk that can be the starting point for an attack. Resolving these contradictory events is a key safety and security concern.

“Ansys simulation solutions are very helpful in visualizing the conflicting structure of safety and security requirements and ensuring traceability, as they allow for centralized management of requirements and design models from different perspectives, while providing an overview of the entire process,” Hashimoto says.

Hitachi Industry & Control Solutions engineers use medini analyze to aggregate and analyze a single architecture, helping them to achieve an optimal design in terms of safety and security. They also use SCADE Architect in the item definition process, which allows for a step-by-step detailed design of the architecture that will be the scope of safety and security. The architecture can then be imported into medini analyze, which ultimately leads to the elimination of inconsistencies in the analysis target and in analysis granularity.

“We believe that this kind of collaboration between simulation software products is the greatest advantage of using Ansys tools,” Hashimoto says.

The MBSE approach using Ansys SCADE Architect models the entire system from various perspectives to provide a common understanding between experts in different domains of safety and security, contributing to the derivation of optimal architectural solutions.

“From an engineering firm’s perspective, introducing the MBSE approach to a development site that is in turmoil due to the development of a large and complex system has the effect of promoting project efficiency,” Hashimoto says, “because it enables the site to separate design and development work by organizing what needs to be done and for what purpose as part of system development. We believe this is the ROI for our engineering firm.”

Using systems engineering and MBSE approaches, Hitachi Industry & Control Solutions has participated in 35 projects for 13 companies over the last 10 years. With the help of Ansys simulation solutions, they hope to increase this number significantly in the next 10 years.

“We will expand the value we provide to the entire workplace for the life cycle of their products,” Hashimoto says. “With Ansys tools and Hitachi Industry & Control Solutions’ MBSE-focused engineering, we will support autonomous development in the automotive field and help customers solve their manufacturing issues in a more connected society.”

Sign up for the on-demand Digital Safety Conference to discover solutions for MBSE, systems engineering, safety, embedded software, and cybersecurity!