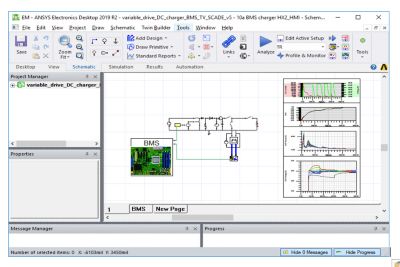

Battery Cell Modeling

EIS data-based battery cell/module modeling can convert frequency domain testing data into a time domain battery impedance model.

System Level Modeling

System level virtual compatibility testing can be used for virtual testing of compatibility standards or be used for root cause analysis of real EMI challenges for existing product.

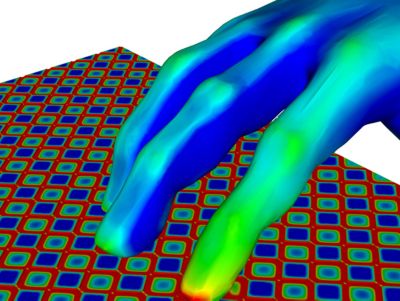

Parasitic Component Modeling

FEA-based battery parasitic modeling can extract parasitic elements of battery package components using geometric information and material properties.