Ansys Rocky

Logiciel de simulation de dynamique des particules

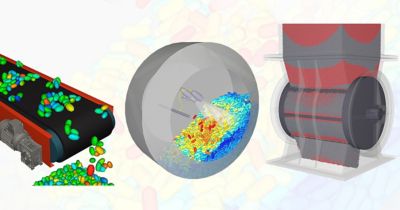

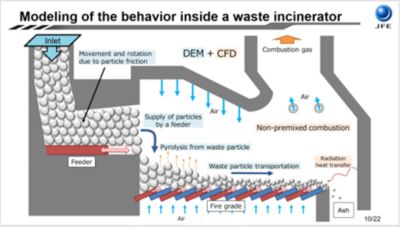

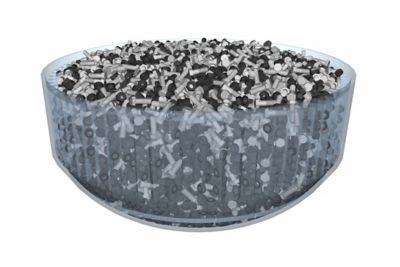

Ansys Rocky est un logiciel de méthode des éléments discrets (DEM) de pointe capable de simuler rapidement et précisément le comportement du flux de particules.

Simulez rapidement et précisément les flux de particules

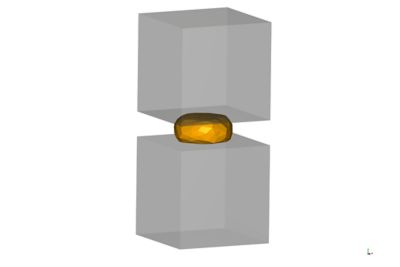

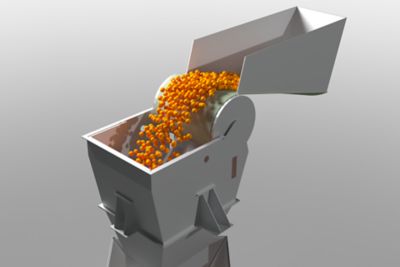

Rocky est conçu pour résoudre les problèmes d'ingénierie. Rocky est uniquement capable de modéliser des formes de particules réelles, y compris tous les solides, les coques en 2D et les fibres rigides et flexibles. Les simulations sont rapides et précises. Grâce aux solveurs dotés de plusieurs unités de traitement graphiques (GPU), simulez le comportement de particules de différentes formes et tailles dans de nombreuses applications industrielles.

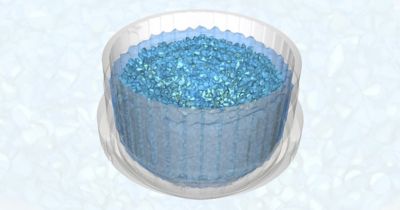

Une solution personnalisée pour les appareils de cuisine

Utilisation du DEM pour concevoir un échangeur de chaleur plus robuste

Par rapport aux tests des composants des plans de travail, la simulation globale des salissures peut permettre de réduire jusqu'à 10 % les coûts de développement totaux, mais aussi d'accélérer le délai de commercialisation en fournissant des résultats en seulement une semaine au lieu de quelques mois.

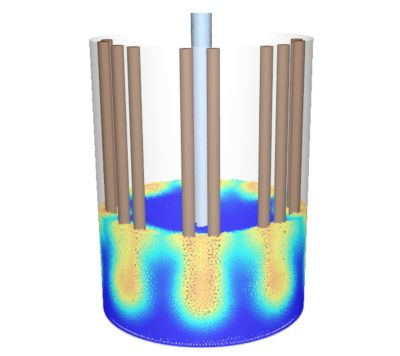

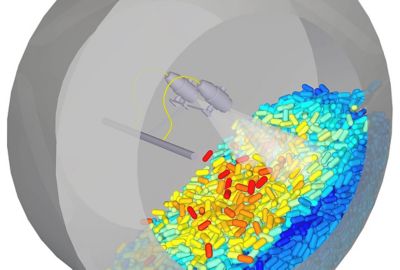

Aujourd'hui, la plupart des cuisines haut de gamme disposent d'appareils encastrés qui doivent être parfaitement intégrés aux meubles attenants, posant alors des défis techniques liés à la restriction du flux d'air dans le compartiment qui leur est réservé. Ce problème est accentué par l'accumulation de saletés sur le condenseur (échangeur de chaleur), ce qui peut affecter les performances de l'appareil.

L’évaluation expérimentale de l’accumulation de saleté sur les condenseurs prend beaucoup de temps et coûte cher. Par conséquent, Sub-Zero associe Ansys Fluent computational fluid dynamics (CFD) et Ansys Rocky discrete element modeling (DEM) pour obtenir rapidement un aperçu des mécanismes à l’origine de l’accumulation de saleté dans le but de concevoir un échangeur de chaleur plus robuste.

Juillet 2025

Quoi de neuf

La version 2025 R2 d'Ansys Rocky permet de prendre en compte les forces DEM/SPH dans les simulations de couplage structurel bidirectionnel avec Ansys Mechanical. Les particules déformables, qui constituent une fonctionnalité bêta, permettent de simuler de grandes déformations élastiques et plastiques de particules solides. Le nouveau module de pulvérisation de liquide DEM, qui apporte des éléments physiques supplémentaires, est désormais disponible au téléchargement. Cette dernière version comprend l'assistance thermique des cas semi-résolus.

Simulation DEM

Les particules déformables (Beta) permettent une déformation importante des particules ; le modèle de contact EEPA (Edinburgh-Elasto-Plastic-Adhesion) permet des forces d'adhérence en traction entre les particules sous compression ; le nouveau module prêt à l'emploi de pulvérisation de liquide DEM (bêta) est disponible au téléchargement, de même que le script de gestion du stockage des matériaux (Local / Ansys Granta).

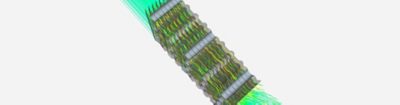

Couplage multiphysique

Assistance thermique semi-résolue qui couple les simulations Rocky-Fluent ; couplage structurel bidirectionnel avec FSI (interaction fluide-structure) où Rocky envoie les forces DEM/SPH au module de couplage mécanique et électromagnétique ; amélioration de la modulation de champ qui permet de moduler les nuages de points statiques selon une forme d'onde prédéfinie.

Performances et facilité d'utilisation

Prise en charge des nuages de points pour les propriétés vectorielles et améliorations de la facilité d'utilisation, importation d'un fichier .msh en tant que particule ; meilleures performances lors du chargement des propriétés pendant le script ; les coefficients utilisés pour calculer la traînée, la portance et les transferts de chaleur sont désormais exposés en tant que propriétés des particules ; entrée volumétrique orientée.

FONCTIONNALITES ROCKY

Résolvez facilement les simulations de particules les plus importantes et complexes

Ansys Rocky vous aide à résoudre les simulations DEM les plus complexes. Les simulations à grande échelle, allant jusqu'à des millions de particules, peuvent être résolues en utilisant des particules de forme réelle sur plusieurs GPU.

Caractéristiques principales

Rocky est un outil de pointe permettant de simuler rapidement et précisément le comportement de matériaux en vrac présentant des formes de particules complexes et différentes tailles.

- Traitement multi-GPU

- Des particules complexes de forme réelle

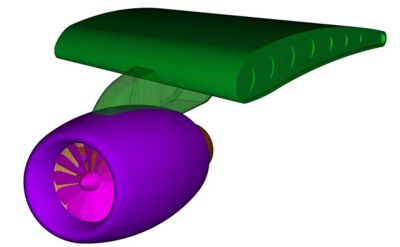

- Couplage de fluides

- Couplage mécanique structurel

- Couplage électromagnétique

- Dynamique multi-corps

- Modélisation des ruptures

- Hydrodynamique des particules lissées

Webinaires en vedette

Ansys 2025 R1 : Nouveautés Ansys Rocky

Rejoignez-nous dans ce webinaire pour découvrir toutes les nouvelles fonctionnalités de la version 2025 R1 d'Ansys Rocky.

Webinar Series

Série de webinaires Ansys Rocky

Cette série de webinaires comprend des démonstrations de 15 minutes montrant comment utiliser Rocky pour résoudre certaines de vos simulations de particules les plus complexes.

Ansys 2024 R2 : Nouveautés Ansys Rocky

Participez à ce webinaire pour découvrir toutes les nouvelles fonctionnalités de la version 2024 R2 d'Ansys Rocky, notamment les améliorations apportées au couplage Rocky-Mechanical, la prise en charge des nuages de points transitoires, le pré-traitement et le post-traitement avec l'intégration d'Ansys EnSight et la nouvelle interface IISPH.

Webinaires à la demande

BLOGS

Études de cas

Le logiciel Ansys est accessible

Il est essentiel pour Ansys que tous les utilisateurs, y compris les personnes en situation de handicap, puissent accéder à nos produits. A ce titre, nous nous efforçons de respecter les exigences en matière d’accessibilité basées sur le US Access Board (section 508), les règles d’accessibilité des contenus Web (WCAG) et le format actuel du modèle d’accessibilité volontaire des produits (VPAT).

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.