Quick Specs

By Integrating within Ansys Workbench and its own native-user interface, Ansys Autodyn has long led the industry in ease of use, enabling you to produce accurate results with the least amount of time and effort.

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

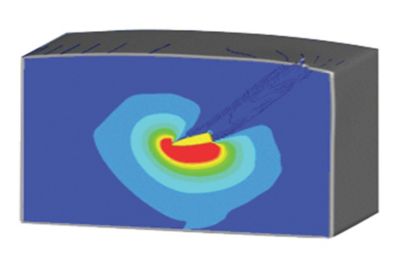

Simulate the response of materials to events ranging from short duration severe mechanical loadings, high pressures and even explosions. Ansys Autodyn provides advanced solution methods without compromising ease of use.

Ansys Autodyn makes it easy to quickly understand and simulate large material deformation or failure. Autodyn has a range of models to represent complex physical phenomena such as the interaction of liquids, solids and gases; the phase transitions of materials; and the propagation of shock waves.

By Integrating within Ansys Workbench and its own native-user interface, Ansys Autodyn has long led the industry in ease of use, enabling you to produce accurate results with the least amount of time and effort.

Technology from Ansys helps to optimize the precise timing of delayed detonations to get the biggest bang for the buck in the mining industry.

The key to optimal blast performance is a series of well-planned explosions. Rows of explosive-filled holes are set off with electronic detonators in a precise-delay timing sequence, measured in milliseconds.

In today’s mining operations, explosive blasts are just as much about precision control as brute force. For efficiency, miners must use enough explosives to fragment and move as much material as possible—but the amount of explosive energy is constrained by budgets and limits on blast vibrations. If timed correctly, shock waves reinforce and amplify one another to produce maximum fragmentation and movement of rock, ore, coal and other materials

With so many variables, mining operators must determine the right detonation delay, often through trial and error. Even after months of experimentation, many companies settle on a delay that gets the job done satisfactorily rather than finding the optimal delay. The largest supplier of explosives in the industry, Orica, is studying precise-delay timing, using Ansys Autodyn nonlinear explicit dynamics software for risk assessments of explosives manufacturing, to give the mining industry a better alternative

The smooth particle hydrodynamics (SPH) solver completes the picture to provide everything needed for explicit analysis. Ansys Autodyn lets you select from different solver technologies so the most effective solver can be used for a given part of the model.

The Lagrangian FE solvers enable fast and efficient solutions when looking at structural components subjected to shock loading and large deformations. Two Euler solver formulations give you the ability to model high speed fluid flow, as well as an alternative way to simulate extreme plastic flow of solid materials.

Ansys Autodyn offers a way to simulate your experiment set up so you can reduce and simplify physical testing

Ansys Autodyn lets you select from different solver technologies so the most effective solver can be used for a given part of the model. The Lagrangian FE solvers enable fast and efficient solutions when looking at structural components subjected to shock loading and large deformations. Two Euler solver formulations give you the ability to model high speed fluid flow, as well as an alternative way to simulate extreme plastic flow of solid materials.

Lagrange-Lagrange, SPH-Lagrange and Euler-Lagrange interactions can all be created within the model in a simple and intuitive manner. This allows fluid structure interactions to be simulated with ease.

To help you with this, Autodyn’s material library contains over 150 prepopulated material models covering most common engineering alloys, brittle and granular materials, orthotropic materials and energetic and explosive compounds.

This combination of models gives you the ability to simulate various material phenomena such as nonlinear pressure response, strain hardening, strain rate hardening, thermal softening, compaction of porous materials, orthotropic behavior, crushing damage, chemical energy deposition, tensile failure and phase changes.

Ansys Autodyn is integrated into Ansys Workbench, taking advantage of CAD import, geometry clean up, model set up, material definition and interoperability with other Ansys analysis systems.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.