Targeting sustainability goals can present challenges in some industries, as notable carbon-reduction initiatives like Race to Zero aim to halve emissions by 2030 and reach net zero by 2050. This has increased interest in direct air capture (DAC) technology, which removes carbon dioxide (CO2) directly from the atmosphere and enables it to be stored underground or converted into climate-neutral carbon products.

Established in 2022, Octavia Carbon is dedicated to reversing climate change by reducing CO2 levels in the atmosphere with DAC technology. Based in Kenya, the startup is the first DAC company in the Global South and uses its location to its credit. By leveraging Kenya’s abundant renewable energy sources, geology, and skilled workforce, the company says it is uniquely positioned to reduce DAC costs and accelerate DAC’s global impact.

Seeking a robust physics-based simulation tool for its engineering design process, the team adopted Ansys simulation solutions in 2023 with the help of the Ansys Startup Program and Qfinsoft (Pty) Ltd., an Ansys Select Channel Partner. Today, Octavia Carbon uses Ansys simulation to inform product design through structural, fluid, and thermal analyses. At the same time, virtual testing and prototyping minimize the time and cost of traditional physical methods, accelerating product development.

Understanding the DAC Difference

Simply put, DAC captures CO2 directly from the atmosphere, whereas point source carbon capture targets CO2 emissions at their source, such as power plants and industrial facilities. Is one method better than the other? Hannah Wanjau, thermal engineer at Octavia Carbon, says both methods contribute to carbon reduction, serving different purposes with unique benefits.

Point source capture prevents CO2 from entering the atmosphere at the moment of emission yet is limited to specific sites and doesn’t address existing atmospheric CO2, she says. On the other hand, DAC removes existing CO2 from the air and can be deployed anywhere with adequate renewable energy, making it more versatile.

“DAC, therefore, will play a vital role in addressing legacy emissions — CO2 that has accumulated over the centuries — and in offsetting unavoidable residual emissions from sectors like aviation and heavy industry,” she says. “By focusing on the removal of atmospheric CO2, DAC complements point source capture, contributing to both net-zero targets and the potential for net-negative emissions to help reverse climate change.”

To enhance Octavia Carbon’s DAC technology, Wanjau and fellow engineers looked toward Ansys for a strong multiphysics simulation solution.

“Our technology involves moving gases, and we needed a tool that could enable us to optimize the design of our technology for the lowest costs, highest performance, and highest safety standards,” says Victoria Barasa, fluids engineer at Octavia Carbon.

Engineers at Octavia Carbon use Ansys simulation for both computational fluid dynamics (CFD) and finite element analysis (FEA) while designing direct air capture (DAC) technology and equipment.

Another advantage to DAC is that the captured CO2 can be permanently stored in deep geological formations, preventing its rerelease into the atmosphere. In addition, the captured CO2 can be transformed into valuable products, such as synthetic fuels, building materials, and plastics.

But that’s not all. Octavia Carbon engineers say DAC technology offers high measurability and scalability, which ensures transparency in carbon removal efforts. It can also be scaled with a smaller land footprint since it is not confined to specific regions and can be deployed apart from emission sources, unlike point source carbon capture.

“Ansys has been an excellent partner on the engineering design front, enabling us to carry out detailed structural, fluids, and process simulations, which has accelerated our product development by helping us cut down on physical prototypes, which speeds up product development cycles, reduces costs, and enhances the safety of our technology,” says Barasa.

Simulating Successful DAC

DAC is a two-stage cyclic process with capture and release phases. Octavia Carbon’s DAC systems comprise industrial equipment and physical components housed within one unit, including contactors such as fans to draw air into the system, sorbent beds to filter CO2 from the air, and heating systems to release the captured CO2 from the sorbent material. Engineers at Octavia Carbon say the sorbent — a solid CO2 filter material — is central to the technology and housed in the DAC units to maximize efficiency. In addition, compressors are used to condition the released CO2 and prepare it for geological storage while control equipment like sensors monitor CO2 concentration.

The team uses Ansys Fluent fluid simulation software to validate the heat transfer rate from Octavia Carbon’s proprietary heat exchangers to the contactor material. Computational fluid dynamics (CFD) analysis is also used to predict and validate airflow and steam flow patterns within the DAC units during design. Barasa deems CFD analysis essential for validating the startup’s custom-made thermal concepts before fabrication and implementation.

“It enables us to accurately design and size fans, blowers, and steam delivery systems,” she says. “Additionally, it supports decision-making around the implementation of steam conditioning equipment based on CFD results.”

Octavia Carbon’s DAC technology contains several physical components, including air contactors, sorbent beds, heating systems, and compressors housed within one unit.

The engineers also use Ansys Rocky particle dynamics simulation software for discrete element method (DEM)-CFD coupling to determine the behavior of the adsorbent contactor material when it interacts with air at varying velocities. This provides critical insight into the air threshold velocity required to accurately size fans and blowers for different adsorbent materials, Barasa says.

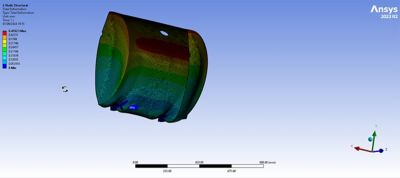

Outside of fluids simulation, the team uses Ansys Mechanical structural finite element analysis (FEA) software for thermal and structural simulations on pressure vessels, such as the external shell of a DAC unit. The team also uses it for load analysis to ensure the integrity and durability of internally built lifting equipment, such as cranes.

Octavia Carbon engineers use Ansys Mechanical structural finite element analysis (FEA) software for thermal and structural simulations on pressure vessels, such as the external shell of a DAC unit.

Octavia Carbon credits Ansys for making simulation more accessible through the Ansys Startup Program.

“Ansys has also enhanced innovation by empowering us to explore a wider range of designs, which helps us to advance our DAC technology,” Wanjau says. “Additionally, affordable access to resources like the Ansys Learning Hub and AnsysGPT artificial intelligence-powered virtual assistant has been instrumental in building our team’s knowledge and enabling us to develop and apply advanced simulation skills to improve our technology.”

Wanjau says Qfinsoft has also been pivotal to the software’s successful integration.

“Qfinsoft (Pty) Ltd. has been instrumental in introducing and supporting the integration of Ansys simulations at Octavia Carbon,” she says. “They provided an excellent introduction to the extensive capabilities of Ansys software for modeling complex multiphysics problems. Moreover, through their support, we have access to a team of experienced engineers in the simulation field who have been invaluable in helping us expand our knowledge and diversify our skill set.”

Maximizing Nature’s Bounty

The startup maximizes Kenya’s natural resources, emphasizing that Kenya’s grid is 93% renewable, with approximately 48% of this energy coming from geothermal sources.

“We have designed our DAC technology to integrate directly with geothermal energy,” says Wanjau. “While DAC-geothermal integration has already been proven, we are building upon the existing success by optimizing our system to significantly reduce the cost of both DAC operations and geothermal energy utilization. Geothermal heat, which is cheap, abundant, and clean, will run the most energy-intensive processes in our DAC approach, like desorption heating, cooling, and vacuum generation.”

Wanjau expects the integration to support up to 80% of the energy required for the startup’s pilot DAC and storage plant in the Great Rift Valley called Project Hummingbird — the world’s second DAC and geological storage installation.

The company considers Kenya’s geology advantageous to DAC with locations like the Great Rift Valley, which has abundant basalt formations ideal for storing captured CO2.

Another benefit of Kenyan operation is having a relatively low-cost manufacturing base, the startup says.

“Through local capacity building, we have developed a skilled team of 62 professionals, including over 40 engineers, to meet the demands of the emerging climate tech sector,” says Barasa. “This approach not only grants us faster learning curves but also promotes socioeconomic development in the region.”

Project Hummingbird, Octavia Carbon’s pilot DAC and storage plant in Kenya’s Great Rift Valley

In addition to its project site, the team has a research and development (R&D) and manufacturing facility in Nairobi.

Envisioning a Cleaner Future

Octavia Carbon has long-term sustainability goals. It aims to remove over a million tons of CO₂ from the atmosphere by 2030 and drive sustainable innovation by empowering industries like sustainable aviation fuels (SAFs) and green steel.

To accomplish these goals, the startup plans to scale its DAC technology while driving down costs with Ansys simulation.

“Ansys simulation will be instrumental in cutting down the cost of our DAC technology by enabling virtual prototyping, which reduces the need for traditional physical prototypes, and the creation of digital twins for real-time monitoring of technologies, helping identify and resolve costly faults and even predicting future performance of machines,” Wanjau says.

To learn how Ansys can support your early-to-mid-stage business, visit the Ansys Startup Program.

Just for you. We have some additional resources you may enjoy.

“Ansys simulation will be instrumental in cutting down the cost of our DAC technology by enabling virtual prototyping, which reduces the need for traditional physical prototypes, and the creation of digital twins for real-time monitoring of technologies, helping identify and resolve costly faults and even predicting future performance of machines.”

— Hannah Wanjau, thermal engineer, Octavia Carbon