Streamlining electric vehicle battery production using multiphysics simulation can drive down costs and increase consumer sales.

According to a report from the International Energy Agency (IEA), electric vehicle (EV) fleets are projected to grow by a factor of eight globally by 2030. Yet, in the United States, EV inventories on dealer lots increased by 506% compared to a year ago. That means, on average, an EV will sit on the market 18 days longer than a gas-powered vehicle.

There are several reasons for this. Apart from range considerations, the biggest factor contributing to the rate of adoption is price. So why are EVs cost-prohibitive for most consumers?

"If you look at the price of an electric vehicle today, currently 30% to 40% of the total cost of that vehicle can be attributed to the battery," says Padmesh Mandloi, Asia-Pacific regional vice president, Ansys Customer Excellence. "Additionally, if the battery doesn't work or needs replacing after so many miles, the burden of cost is passed along to the consumer. This has had a chilling effect on the marketplace, particularly in the United States, where EV production seems to have hit a speed bump."

Optimizing Battery Production Processes With Simulation

Now for some good news. Leading global financial institution Goldman Sachs sees a bear market on the horizon for raw materials commonly used in EV batteries, such as nickel and lithium, as supply is catching up and cooling overall demand. Next year, we'll most likely see EV prices begin to drop.

There is another reason for the 40% decline in battery prices predicted to happen between now and 2025. To further reduce costs, manufacturers are reducing complexity through simpler packaging. They're also making better material choices — like silicon, for example — that simultaneously reduce charging time and increase energy density to deliver even more energy for the same amount of weight.

But sticking with more traditional manufacturing approaches to execute on these ideas puts limits on efficiency and sustainability. Without any significant deviations, they will most likely continue to struggle to optimize production processes, identify cost-saving opportunities, and address sustainability concerns effectively.

Lacking a clear methodology for improving processes, manufacturers find themselves caught in a drawn-out build/experiment/waste/repeat cycle. Simulation delivers the insights needed to address various stages of the manufacturing process and production line development that can reduce these costly trial-and-error experiments and improve up time. Without data insights coming out of simulation, this level of complexity is nearly impossible to address.

Across the EV battery market, battery cell manufacturers are tackling numerous technical engineering challenges in a virtual environment. They're leaning in on simulation to meet customer specifications, reduce costs, maintain quality, ensure safety and compliance, address labor shortages, and improve end-of-life battery disposal and recycling with positive results.

"More battery manufacturers are leveraging physics-based simulation and safety analysis to gain valuable insights during production," says Mandloi. "Ansys' simulation tools and solvers enable them to optimize battery designs, as well as identify suitable equipment and workflows on the factory floor that can increase scalability, quality, and sustainability in the process."

One Ansys customer, UK Battery Industrialization Centre (UKBIC), a national battery manufacturing scale-up facility, leans in on simulation to provide skills for the growing battery sector. This facility plays a key role in developing battery technology and skills supporting electrification in the UK using Ansys multiphysics software.

"At UKBIC, we support our clients in bringing battery technologies to market amid rapidly rising costs and intense industry pace,” says Dr. Timothy Addison, head of digital at UKBIC. “Efficient use of resources and a strong commitment to predictive modeling and simulation are crucial for commercial success. We cannot rely on chance for large-scale manufacturing; instead, we use the Ansys suite of solutions to refine product designs and process setups, ensuring readiness before each manufacturing campaign begins."

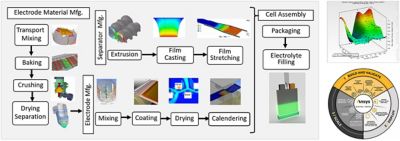

This diagram captures various steps in lithium-ion battery manufacturing. Simulation presents significant optimization opportunities throughout the entire process.

Ansys’ breadth of physics and depth of capabilities cover many aspects of the battery production process (pictured above). For instance, during the coating process accurate, multi-phase simulation with Ansys Fluent fluid simulation software can test many conditions and geometries of the coater virtually before the physical prototype is prepared.

This figure of machinery (left) and the animation (right) are simulations of the continuous coating process. Ansys simulation tools accelerate the design and optimization of this entire process.

After this coating is applied, it needs to go through a compaction process called calendaring (also pictured above), which has significant impact on the pore structure and performance of Li-on battery cells. With Ansys Rocky particle dynamics simulation software, it’s possible to look at the microstructure level during the calendaring process and, together with Ansys Mechanical finite element analysis (FEA) software for structural engineering and Ansys LS-DYNA multiphysics software, identify the residual strains resulting from compression during this process, especially if there are imperfections.

"Battery manufacturing is very dynamic," says Akira Fujii, principal application engineer at Ansys. "At the same time, engineering goals on the customer side highlight the need for both process and equipment optimization to maintain consistent quality, or improve on it, while satisfying specific criteria. A film coating process that lacks uniformity in thickness, for example, or a change in material thickness impacting geometry are just a few of many scenarios that can be quickly evaluated and addressed in a simulation environment."

Manufacturers Look to Digital Twins for Operational Success

One transformational battery manufacturing trend on the horizon involves further digitization of production enabled by digital twins. Manufacturers can develop digital twins using sensor data and simulation data. These models, or virtual representations, of real-world production processes can be used to understand and improve the entire manufacturing process. They can also be applied to specific corner cases to understand where a process can potentially fail — followed by predictive analytics or predictive maintenance to identify the conditions leading up to this failure.

Ansys provides digital twin-driven analytics solutions to battery manufacturers to sensitize the entire manufacturing process. This includes the delivery of virtual sensor data to provide insights to customers about the process, the quality of the product, and where failures could happen at any point along the way. In this case, reduced-order models (ROMs) capturing critical aspects of the digital twin would be used to generate data that can be fed into an analytics engine to do predictive maintenance.

"We're currently exploring various ways we can connect simulation-based digital twins and do the whole sensitized analytics process because training the analytics engine takes a lot of time and requires a lot of data," says Mandloi. "If you simply wait for that data to come through the natural process, it can take you a year or maybe two years before your engines are really able to make predictions. So how can you fast-track that process? One way of accelerating it is to enrich that engine with a lot of data coming from simulations where you've tried multiple design of experiments (DOE) variations and you’ve fed all of that data back to that engine."

Ansys Addresses a Pressing Need for Solid-State Solutions

An ongoing challenge for battery manufacturers involves the search for a safer, more efficient alternative to Li-ion batteries. The introduction of solid-state batteries promises improved safety and can deliver higher energy density over a much wider operating range in a smaller, more flexible form factor. And since the manufacturing process of solid-state batteries does not include a drying process, suppliers can shave off development time to make inventory faster and cheaper.

Simulation is integral to moving this battery technology forward. Ansys' efficient, seamless workflow for a solid-state battery solution, including many multiphysics tools, enables identification of optimal particle size distribution, material mixing ratio, and compaction pressure.

Ansys simulations support design optimization for all processes related to battery creation with the process integration and design optimization (PIDO) platform and digital twin technologies.

Finding Greater Efficiencies With Ansys

We've touched on the benefits of a comprehensive, simulation-driven digital engineering strategy for EV battery manufacturing. Every day, engineers are using a combination of Ansys simulation to gain valuable insights — to optimize battery designs and identify suitable equipment and workflows for scalability, quality, and sustainability.

Don’t miss Powering Progress: Leveraging Simulation for EV Battery Design, Production, and Integration to learn more about Ansys software solutions for battery manufacturing and production processes.