-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

November 24, 2021

How Continental Uses Electromagnetic Simulation for RF Human Exposure Assessment

At Continental, we imagine tomorrow's vehicle will always be connected, user-friendly, comfortable, and intelligent. We develop wireless solutions to connect vehicles with drivers and passengers, but also with the surrounding environment — anywhere and anytime. This requires developing a full antenna portfolio, from complete mechanical design to printing on electronic PCBs, to ensure communications between smartphones, the infrastructure, other cars, and the cloud.

A major challenge in building a complete antenna portfolio is ensuring the safety and health of our customers when using wireless devices. Anyone who has used a microwave oven knows that at high power and frequencies, electromagnetic radiation can cook animal tissue if given enough time. Even if our communications devices are operating at much lower power levels, we still must meet international radiation standards to guarantee that consumers will not be negatively affected by our antenna systems.

For more than fifteen years now, Ansys HFSS has helped us design our products while saving development time and money.

Regulatory Standards

Scientists have established that electromagnetic fields can interact with human bodies in two ways: low frequency radiation below 100 kHz at high field levels can stress the human nervous system, while high frequency radiation up to 10 MHz can cause heating of human tissue. Between these two extremes, both neurostimulation and heating effects can occur.

Individual governments are responsible for product safety requirements in their own countries. Organizations such as the FCC, ISED, ETSI, and others establish regulatory standards to be followed for exposure assessment and certification. Most of these organizations follow recommendations from ICNIRP and IEEE.

With variations among countries, these regulations protect the user from exposure to even small temperature increases to prevent biological malfunctions. The most famous criterion is the well-known “Specific Absorption Rate” (SAR) for cell phones. The SAR indicates the rate of absorbed energy per unit tissue mass exposed to an electromagnetic field, which is related to temperature elevation and to the electrical field magnitude. A common standard is that human exposure should not exceed 2 W/kg over a six-minute time-average of SAR absorbed by 10 g of human head tissue.

This assessment is usually done by physical measurements according to IEEE/IEC 62209 standards, but in recent years it has become possible in some countries to substitute physics-based simulation for physical measurements according to simulation standards IEEE/IEC 62704. Governmental regulations are always evolving due to new technologies, so you should consult the latest version of the appropriate standard in your country to be sure you are compliant.

Electromagnetic Simulations at Continental

At Continental, we were looking for simulation software that was well-recognized by governmental authorities for exposure calculations, and which was also compliant with standards. This led us to choose Ansys HFSS full-field electromagnetic solver available in the Ansys Electronic Desktop for our antenna design. Historically, only finite difference time domain (FDTD) solvers for simulating time-varying fields were standardized. We were using the static (non-time varying) finite element method (FEM) of HFSS, which was recognized by the FCC. When the latest IEC62704-4 standard released in 2020 included a peak SAR calculation algorithm for FEM solvers, Ansys worked hard to develop and implement this standard in 2020. The process involves modeling the antennas with the relevant part of device while adding a phantom model of the human head. Then, the HFSS calculator proposes an algorithm which searches for the maximum average peak SAR into the phantom volume. This helped Continental convince governmental authorities that HFSS could be used to meet the exposure compliance assessment.

Simulation also helps us create a virtual testing scenario since we obviously cannot test live human tissue to prove that worst-case exposure conditions remain under the SAR limit. In addition, electromagnetic simulation has helped us integrate our antennas into vehicles safely to protect the health of consumers.

Because making SAR measurements is not in one of our core competencies, we use certified external laboratories for this. So, reducing the number of external measurements is a key to decreasing development time and cost, especially for Wifi, Bluetooth, and e-call technologies for which a large number of channels have to be evaluated to cover all GSM, UMTS, and LTE channels. Testing only one final design saves lots of time and money.

Example Simulations

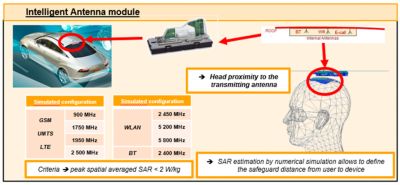

Car manufacturers are increasingly installing “intelligent antennas” for e-call telephony applications under the roof in the vicinity of the heads of rear passengers. Exposure to electromagnetic radiation could be significant, especially for tall passengers. The car manufacturer defines the module’s integration into the roof of the car, specifying the minimum exposure distance between the device and a passenger’s head (the “safeguard” distance). Using simulation models and HFSS, we are able to determine whether the radiated power conforms with SAR limits and validate whether the proposed safeguard distance is acceptable or not.

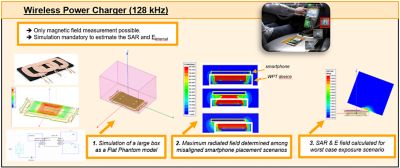

Another device that we simulate using HFSS at Continental is the wireless power charger for smartphone applications using magnetic induction. Because this device is usually located on the console between the two front seats or sometimes in the armrest of rear seats, it is close to the passengers. Continental engineers solved this problem by developing a dedicated simulation method based on “digital homologation process.” This process includes evaluation of the wireless power charger working at 128 kHz at both low and high frequencies to assess the internal electric field and the SAR requirements. No physical testing setups were available to make these measurements, so they could not be certified without numerical simulation.

Assessing HFSS

Continental engineers’ experience with HFSS is very positive for antenna design and exposure assessment. The software is easy to use and assistance from the Ansys Customer Excellence (ACE) team is always welcome since there are a lot of options and possibilities to explore. We appreciate this support and the efforts that Ansys makes to continuously evolve the software to meet the latest design challenges.

Using simulation greatly reduces development time, which is of great importance to Continental. But something that is often overlooked is that simulation helps engineers to improve our understanding of the physics, for example, by visualizing the propagation EM fields. We cannot quantify this benefit, but it has a major impact on our continuing efforts to expand our knowledge and enhance our products.