-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

Designing safety into vehicles isn’t just good business or a regulatory requirement. For the automotive industry safety is a moral imperative. Accidents will happen. When they do, vehicle design can be the difference between life and death for drivers, passengers, and pedestrians. Safer designs also mitigate the economic burdens of crashes on individuals, healthcare systems, and society.

In essence, a lot rides on the industry’s ability to make every vehicle as safe as possible.

While “safety at any cost” is ideal, automotive engineers face countervailing pressures, mostly in the form of reduced developmental timetables and budgetary limitations. As a result, engineers may be forced to prioritize safety aspects thought to reduce accident severity or to seek more cost-friendly strategies, such as the phased implementation of safety features.

Computer-aided engineering (CAE) has become an integral part of the vehicle design process to balance safety and time to market. Virtual analysis enables designers to reliably assess a vehicle’s crash and safety performance while reducing costly physical testing.

Ansys application engineers recently used the Ansys SimAI cloud-enabled generative artificial intelligence (AI) platform to quickly predict how a car bumper would deform during a high-speed, front-end car crash.

Their efforts demonstrated that the software, which has proven effective in predicting how fluids move, especially in constant motion simulated by computational fluid dynamics (CFD) solvers, also can handle other physics, such as nonlinear, transient structural simulations.

Accuracy and Speed

As vehicles have become more complex, the digital models used in their design have grown in complexity as well. Models are also larger than ever, requiring more compute resources and substantially longer simulation times.

Today, it’s not uncommon to see full-vehicle models with 40 million to 50 million elements, requiring 25 to 30 hours to solve a complete crash event on a modern-day high-performance compute cluster of 700 to 1,000 CPUs. That’s on top of the months engineers already have put in clearing the new computer-aided design (CAD) — removing intersections (overlaps) and penetrations (gaps) that remain after parts and subsystems from legacy programs are reused, a common practice during the early concept phase — meshing the CAD, adding all the necessary connections and materials, debugging for any errors, and establishing a baseline performance.

Even then, CAE models often fail to keep up with all the design changes, unless engineers have clearly defined them and created parameters for each key aspect of the model being changed. Because parameterization is difficult and time-consuming, especially for complex design changes, only a few designs are ever evaluated thoroughly.

That’s where the power of the SimAI platform comes in.

By combining the predictive accuracy of Ansys simulation with the speed of generative AI, the SimAI product can predict the full 3D response of a new design in minutes. For complex, computation-heavy projects, it can predict outputs 10X to 100X faster than a finite element solver.

Speeding up the simulation process enables more design exploration, letting automotive engineers try out additional ideas and innovations and focus on promising designs earlier in the process.

Training Day

SimAI technology is physics-agnostic, cloud-based software that can be trained to work with fluids, structures, electromagnetics, and more.

To show how it could predict a transient event like a car crash, when everything is rapidly and constantly changing, Ansys application engineers started with a “sled” — a simplified Ansys LS-DYNA structural simulation software vehicle model. In this case, the sled simulated the bumper impacting a rigid wall at 15.6 meters (16.4 yards) per second.

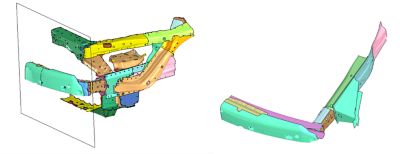

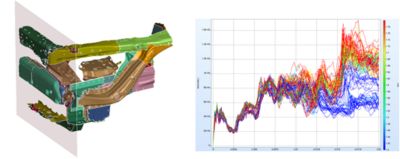

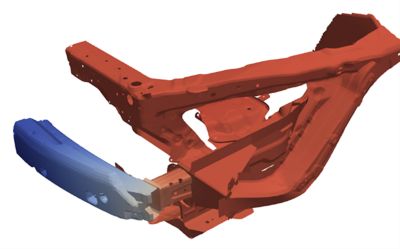

To produce enough data points to accurately predict the transient response, Ansys engineers introduced design variations. Changing the thickness of seven parts within minimum and maximum boundaries generated 98 different designs, each with 21 states — crushed, bent, folded, and so on — for a total of 2,058 training data points.

Bumper crush model. Part thickness of the highlighted parts varied.

Ansys engineers then uploaded the data to the SimAI platform, where it was automatically divided into training, validation, and test sets. The validation set enabled engineers to tune the model’s underlying structure to improve its performance while the test set determined how well the model could handle unfamiliar situations.

Configuring the model came next. That included determining the:

- Boundary (or crash) conditions.

- Inputs — in this case, different points of time during the crash and the thickness of several parts.

- Outputs, rigid wall force (or how much force the wall would experience), and nodal displacement (how far a point marked on the bumper would move up, down, to the left, or to the right).

- Precision level, which directly affects the time required to train the model. “Precise” models take up to two days to train while “very precise” models typically require a week. In this case, the model took about 21 hours to train.

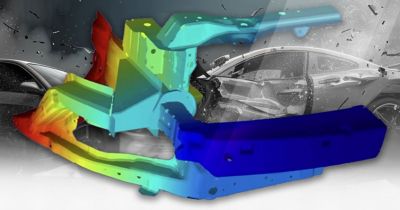

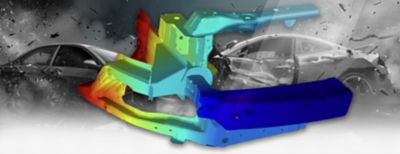

Bumper deformed state and rigid-wall time history plots

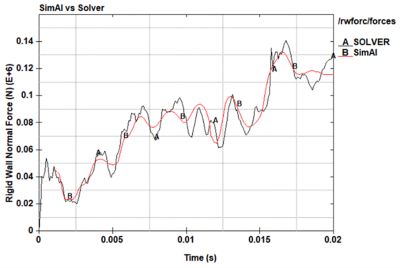

Ansys engineers assessed the accuracy of SimAI software by comparing how well it calculated the force exerted by the wall during the crash with the results of a traditional solver.

Sample .vtp file with a displacement field on the nodes. Geometry is written out in .vtp or .vtu file formats; .vtp holds the surface (shell element) data, and .vtu holds the volume (solid-element) data.

Lined Up

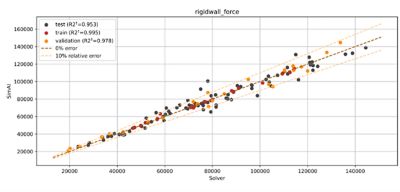

Plotting the predictions made by the solver and the SimAI product revealed a slight discrepancy. While both predicted the bumper’s shape and wall force at the same time steps, the points were not perfectly matched. The AI’s hypothetical points didn’t land exactly on the same straight, diagonal line of the graph as the solver’s.

Ansys SimAI cloud-enabled generative artificial intelligence (AI) platform trend plot for the global coefficient rigidwall_force

This was actually a good thing.

A perfect match isn’t always the best outcome. It might mean that the AI overfitted the training data — that the AI just memorized the specific examples it was trained on, not the underlying rules. An overfitted AI wouldn’t be good at predicting entirely new designs that it hadn’t seen before.

However, because the SimAI software predictions mostly lined up well with the solver’s predictions, it suggested that the SimAI model was accurate without overfitting. The plot also indicated areas where the AI’s training could be improved for even better results.

Comparison of the deformed shape between the solver and the SimAI platform

Comparison of rigidwall_force prediction between the solver and the SimAI platform

Safety, Faster

In the end, SimAI technology proved to be orders of magnitude faster than the traditional solver. It predicted the force on the wall in less than a second and the entire movement of the bumper in about 10 seconds.

Speed isn’t the only advantage over traditional simulation, however. Because the SimAI solution can predict what would happen at every point during a crash (within the limits of the data it was trained on), it provided a more detailed picture of how the bumper deformed — including intermediate states, not just the outcome.

This means it’s possible for automotive engineers to have a single, accurate model for transient, nonlinear events, leading to safer cars that make it to the market faster and with less strain on development budgets.

Download the full white paper, "Ansys SimAI Software Predicts Fully Transient Vehicle Crash Outcomes," and learn more about the SimAI platform.

Just for you. We have some additional resources you may enjoy.

Learn More

Download the full white paper, "Ansys SimAI Software Predicts Fully Transient Vehicle Crash Outcomes," and learn more about the SimAI platform.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.