Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

“The HSD engineering team relies on Ansys Fluent and Ansys Mechanical, delivered via Ansys Cloud, to engineer our existing electrospindle designs for maximum performance, power density, durability, and consistency over time. These solutions help us understand and minimize materials degradation, vibration, thermal buildup, and other physical issues that impact long-term, reliable performance in our customers’ applications. We are also leveraging Ansys Twin Builder to design the electrospindle of the future — which is digitally connected, in real time, with the rest of the factory to create a true zero-defect environment. Together with Ansys and our partners in Italy’s Intelligent Factory Cluster initiative, we are redefining the future of manufacturing.”

— Manuel Camperchioli, Prototypes, Tests and Experiences Manager, HSD Mechatronics

HSD Mechatronics, based in Gradara, Pesaro and Urbino, Italy, is the world’s second-largest manufacturer of electrospindles — machine tools with rotating shafts that support cutting, grinding, milling, and other work processes. A key component of production automation and mechatronics systems, electrospindles are designed to machine metal, wood, composite materials, glass, and stone. HSD provides high-performing electrospindles, many of which require product customization, to customers in the automotive, aerospace, industrial manufacturing, construction, defense, and other industries. These products must operate with incredible levels of precision in mission-critical applications, while being subjected to high-speed mechanical rotation, high thermal loads, and other harsh environmental conditions. HSD relies on a suite of Ansys solutions — including Ansys Fluent, Ansys Mechanical, Ansys Cloud, and Ansys Twin Builder — to not only optimize its existing product designs, but also to produce the extremely innovative electrospindle of the future, which is set to revolutionize manufacturing.

Challenges

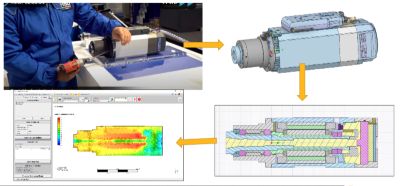

An established global leader in electrospindle design, HSD is a partner in Italy’s prestigious Intelligent Factory Cluster, a public-private partnership aimed at making zero-defect manufacturing a reality. As part of a project called “Electrospindle 4.0,” HSD is developing a next-generation electrospindle that is digitally connected to the rest of its customers’ production environments. This project requires HSD to understand and optimize product performance at an entirely new level — in real time, as the machine is working in a customer facility. Increasing the interconnectivity of its machine tools with the larger production environment means HSD must place physical sensors on each electrospindle that monitor performance in real time. But it’s impossible to place physical sensors everywhere they’re needed due to the complexities of electrospindle operation. So an equally important component of Electrospindle 4.0 is creating an accurate digital twin of the working tool that’s equipped with a series of virtual sensors. Today, HSD must complement its traditional engineering simulations with a new focus: creating a working digital twin of each electrospindle deployed in a customer facility.

Engineering Solution

Since 2019, HSD has relied on a suite of Ansys solutions, including Ansys Mechanical and Ansys Fluent, to simulate the real-world performance of its electrospindles and other machine tools in customer applications. HSD has used this Ansys solution suite to explore improvements such as new materials, as well as investigate issues such as deformation, fatigue, and overheating. HSD has leveraged Ansys Cloud to manage the large numeric problem sizes associated with rotating machinery. When HSD launched the Electrospindle 4.0 initiative in 2020, it added Ansys Twin Builder. Now HSD is able to model a specific tool’s operating conditions in Twin Builder based on live inputs from the digitally connected, working electrospindle — then the virtual model, equipped with virtual sensors, provides even more data points. By gathering data from both physical and virtual sensors, HSD can predict repair and maintenance needs, while gathering a large volume of real-time insights that lead to the continuous optimization of both the product and its performance. Ansys Twin Builder is the perfect solution for building a working model of the electrospindle and connecting it to the live, working tool in a customer’s facility.

The goal of the Electrospindle 4.0 project is to create a digital twin that’s directly connected to a working machine tool. Simulation via Ansys can identify and predict any issues before they impact the performance of the physical electrospindle.

Benefits

Using Ansys Twin Builder to complement physical sensors with virtual sensors reduces the overall costs of digitalization and enables HSD to explore very complex performance parameters — such as the internal workings of the tool — that would not otherwise be possible. While creating real-time connectivity across the factory is still a complex undertaking, the use of Ansys Twin Builder is helping to simplify it, accelerate the overall development process, and drive down the costs of the Electrospindle 4.0 initiative. Whether HSD is using Ansys Fluent, Mechanical, or Twin Builder, simulation has proven critical in reducing development costs, increasing customer satisfaction, and minimizing human labor requirements, which has been increasingly important due to engineering talent shortages. Finally, accessing Ansys software on Ansys Cloud allows HSD to solve large, multiphysics problems like vibration much faster. The company has achieved a 40x acceleration in solution times since it transitioned from using an internal cluster to Ansys Cloud. That enables HSD engineers to run many more simulations and investigate more complex performance issues.

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.