-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

April 13, 2023

What is Automotive NVH?

Ask a child what sound a car makes, and the typical answer is, “vroom-vroom!” Ask an automotive engineer the same question, and the response will be much more complex. From the hum of wind passing a side mirror to the enhanced acceleration of an electric vehicle, the many sounds a car makes are critical to the overall driving experience. To design, identify and optimize automotive sounds, engineers rely on a field called NVH.

What is NVH?

Noise, vibration, and harshness (NVH) is the study and measurement of aural and tactile feedback in an object. Because sounds can be both an annoyance and a benefit, NVH analysis helps identify where a sound is coming from and why. Engineers can then reduce or eliminate unwanted noises, as well as enhance beneficial sounds — such as the signature rumble of a motorcycle — through a combination of simulation and physical testing methodologies.

What Does NVH Stand for?

The three parts of NVH cover a range of sound indicators — how it is heard, how it is felt, and whether it is perceived to be pleasant or annoying.

Noise: the sound propagation caused by a specific object, such as the hum of an opening sunroof, an engine, a door being slammed, an HVAC system, or seat belt buckle clicks.

Vibration: the oscillations that occur at a certain frequency. In a car, vibrations can be felt at different speeds through the steering wheel, seat, armrests, floor, and pedals.

Harshness: the subjective quality associated with noise and vibration. While both noise and vibration are quantifiable measurements, harshness deals with the discomfort of hearing unpleasant sounds. What is harsh to one person may not be harsh to another.

What is NVH in Cars?

NVH techniques are applied across a variety of industries, but they began in the automotive industry to address the rumbling, knocking, and grinding generated by combustion engines.

NVH is currently a key performance indicator in the automotive industry, particularly as more automotive manufacturers begin to electrify their fleet. Vehicle NVH performance can make or break brand image easily, so it is critical to address NVH issues early in the design stage.

Read “How Simulation Helps You Overcome Electric Machine NVH Design Challenges” to learn more.

Sources of NVH in Cars

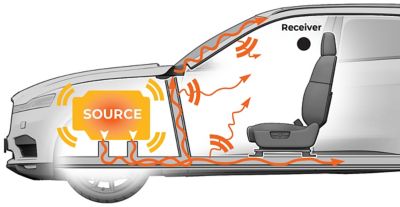

There are three sources of NVH in vehicles:

Aerodynamics: HVAC fans, wind against the car body

Mechanical: brake friction, engine operations, tire contact with the road

Electrical: driver alerts, inverters in electric cars

Being able to identify sounds coming from sources such as the engine, brakes, car body, and interior gives engineers a full audio picture of the vehicle. Once the source of a particular sound is understood, engineers can determine the right sound control techniques, such as substituting materials, changing interaction flows, or installing sound barriers.

To create the best overall driving experience and gain a competitive edge, automotive companies have many sound-based goals that NVH helps them address, including:

- Increase driver and passenger comfort.

- Reduce vibration-based failures.

- Create a desired sound or vibration.

- Adhere to noise regulations.

- Minimize tonal noises.

- Ensure structural reliability and improve lifespan.

- Minimize operator fatigue by providing a quiet environment.

How is NVH Analysis Conducted?

Humming tires, whistling wind, squeaky wipers — there are dozens of sound sources in cars that can be sensed audibly, visually, and tactically. NVH analysis can help reduce or eliminate the undesirable ones. To optimize sounds against desired criteria, engineers can use acoustic solvers for simulating vehicle noise at multiple levels of design.

Acoustics Simulation Levels

- Full-vehicle level

- Noise generated by the full car in motion.

- System level

- Noise coming from machines working together.

- Sub-system level

- Noise coming from a specific machine, such as an e-motor.

- Component level

- Noise generation from an individual element, such as a seat belt click.

To complete an NVH analysis based on different simulation levels, engineers must first create a simulation model that accurately represents the physical system or component. Ansys tools such as Ansys Mechanical, Ansys LS-DYNA, Ansys Fluent, Ansys Motor-CAD, and Ansys Maxwell can be used to simulate and model the necessary components, and post-processing can be performed in Ansys Sound.

Watch “Listen to the Sound of Your Simulations” to learn more about the Ansys acoustics workflow.

Challenges of Simulating NVH

A common mistake engineers make when simulating NVH is that they start right away with highly complex and computationally expensive simulations. This is a problem because those models often don’t match up with physical behavior. As a result, time and resources are wasted on an analysis that doesn’t match physical test results.

It’s important that basic quantities of simulation models like overall mass, stiffness, and damping matrices are well correlated with physical testing using parameters like modal assurance criteria (MAC), coordinate modal assurance criteria (CoMAC), and frequency response assurance criteria (FRAC) before running highly complex analyses.

Getting Started with NVH

Just about every element in automotive design can benefit from NVH analysis. Understanding noise sources and how to optimize them is one of the best ways to ensure your automotive design will meet buyers’ needs and industry standards. Implementing simulation as early as possible in the concept and design phase will help ensure that NVH issues are resolved as possible before physical prototyping begins.

Follow us on our new Acoustics LinkedIn to stay up to date on NVH workflows and simulation tips.