-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

September 9, 2020

Vertical Farming is Coming to a Store Near You

Inadequate consumption of fruits and vegetables is among the top 10 risk factors for our health. Eating fruits and vegetables daily helps prevent major diseases, ensures an adequate intake of most micronutrients and fibers, and can help displace foods high in saturated fats, sugar or salt.

The health benefits of eating more produce can’t be denied, but what about the old adage “fresh is best”? Locally grown fruits and vegetables have distinct advantages. The less time it takes to get to your plate, the better. Once vegetables are picked and harvested, they begin to lose their nutrients. Also, produce that is grown and sold locally has minimal transportation time, which translates to reduced fossil fuel emissions.

It may soon be common for anyone to pluck a farm-fresh tomato from the vine or choose their lettuce while it’s still growing, even if they live in urban areas without gardens. Indoor farms, and even in-store farms, are fulfilling our need for more local vegetables. These semi-autonomous vertical farms offer fresh, healthy food options by bringing food production closer to consumers.

Vertical farms use state-of-the-art technologies, such as specialized LEDs, to help the vegetables grow. Simulation is used to strategically design and optimize indoor farm lighting to create an optimal environment that decreases growing times.

Vertical Farming Lighting Challenges

Engineers designing in-store vertical farms must consider many optical aspects.

First, for a row containing a certain type of plant, it is important to ensure the right illumination value. Different plants need varying amounts of light to grow, and that amount can vary during the growth cycle.

It is also important to ensure illumination homogeneity through a row so all the seeds grow at the same speed. This eases the burdens of plant care during production and allows harvests to be scheduled as needed.

Similarly, when it comes to the light spectrum, plants don’t need all the wavelengths of natural light to grow. Plants respond best to just the red and blue wavelengths, so traditional lamps mimicking sunlight are a waste of energy. Careful optical design can help to optimize LED lighting to target only necessary wavelengths, saving energy in the process.

Lastly, the amount of light absorbed by the plants should be maximized. The less light plants reflect, the faster they grow, which reduces energy consumption.

Vertical Farms Grow with Simulation

LED lights are the most efficient, effective and customer-friendly way to illuminate plants indoors. They use low energy, produce little heat and can be color-optimized for growth.

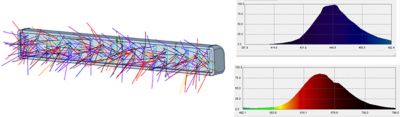

To show how Ansys Speos can be used to design grow-light LED array solutions and simulate an indoor farm, we designed a generic light array with 90 LEDs. According to the literature, a diffuse purple spectrum (containing no green light) is optimal for plant growth. Plants reflect much of green visible light and absorb the rest of the spectrum. Consequently, the light array we created has 45 LEDs in the blue spectrum and 45 LEDs in the red spectrum, combining to make purple.

Grow light array for a purple spectrum

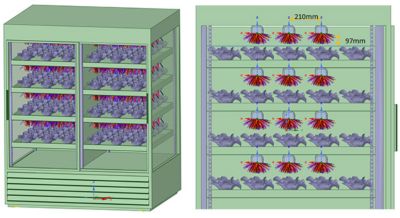

Inside our farm, we first designed eight rows of 15 lettuce plants. Each row is illuminated by three of our purple spectrum light arrays.

Vertical farm isometric (left) and side view.

To take the optical properties (light absorption and reflection) of the lettuce into account, we measured some leaf samples using Ansys’ Portable Optical Measurement Device (OMD). The bidirectional reflectance distribution function (BRDF) obtained was applied to all of the lettuce plants in the geometry.

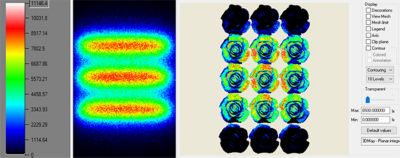

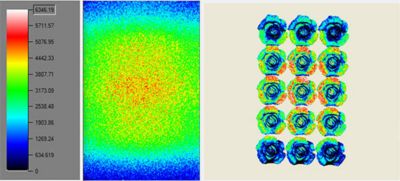

We then used light simulation to measure and visualize illuminance homogeneity, as well as the vegetables’ light absorption. The results obtained for the first design are shown below.

Illuminance sensor (left) and 3D absorption (right)

We could see that the illumination was not homogeneous on the whole row. We then iterated on the LED array’s position, the spectrum of the LED and the material of the walls of the vertical farm to produce the most efficient solution.

Vertical Farming Simulation Results Are Illuminating

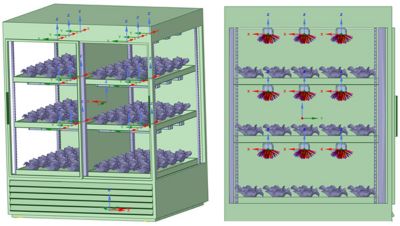

We spaced the luminaires more evenly and gave more space between the LED arrays and lettuce plants. We also changed the materials on the sides and the back from transparent (absorbing) to white (diffusing). The front of the vertical farm was kept transparent so consumers could see the plants as they shopped.

Vertical farm isometric (left) and side view.

Our next simulation showed that the illumination reaching the lettuce plants is more evenly distributed, producing a more uniform light absorption, as shown below.

Illuminance sensor (left) and 3D absorption (right)

However, the lettuce plants in the front and back are a bit less illuminated, so they might not grow as well as the ones in the center. Because the simulation results are so visually striking, it’s easy to determine where the vertical farming design could be improved. One idea for the front lettuce plants would be to apply a partially reflective coating on the inside face of the front glass to reflect more light toward them. The optimized system would then both ensure an optimal harvest yield and optimal energy consumption.

Vertical farming for in-store produce is an idea making its way to the mainstream. Optical simulation helps quantify and visualize the benefits of vertical farms, such as using less energy and water, and growing what is needed in small batches, which wastes less food.

Learn more about optical simulation and Ansys Speos.