-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

July 12, 2022

Turbotech Revs Up Sustainable Aviation with Efficient, Simulation-Powered Propulsion Solutions

Primary challenges in developing efficient propulsion systems for ultralight and light-sport aircraft — vehicles with a maximum takeoff weight of approximately 1,250 pounds — include balancing size, weight, and power while optimizing energy consumption to reduce fuel burn.

But Turbotech, a French-based aeronautical manufacturer, is using Ansys’ multiphysics simulation through the Ansys Startup Program to develop high-powered, low-consumption propulsion systems for ultralight and light-sport aircraft vehicles.

As the first company in the world to introduce regenerative turbines for aeronautical applications, Turbotech offers sustainable flight solutions with turbines as efficient as traditional piston engines. The main ingredient of the revolutionary engine is Turbotech’s signature heat exchanger.

With groundbreaking heat exchanger technology and the continued integration of Ansys’ simulation, Turbotech is propelling small aircraft into a cleaner future with pioneering products, including the first low-fuel burn turboprop, the first turbogenerators for hybrid-electric aircraft, and forthcoming hydrogen-powered turbomachinery.

Turbotech Takes Off

Established in 2017, Turbotech lacked resources and needed access to sophisticated simulation tools. By collaborating with Ansys, the company was able to start development and continues to benefit from Ansys’ simulation software today.

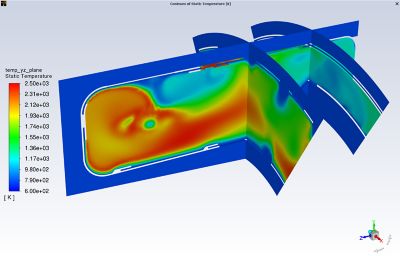

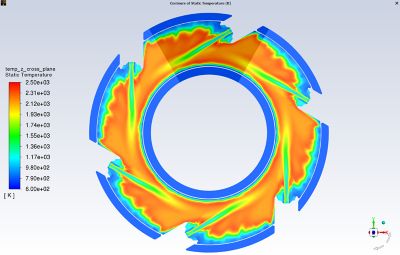

Fluid temperature contours are analyzed in Ansys Fluent using kerosene-air combustion models.

“Our relationship with Ansys has been vital to the success of Turbotech as a company and of our products as well,” says Jean-Michel Guimbard, chief technology officer at Turbotech. “The Ansys Startup Program equipped us with the tools and resources we needed to launch our business, and today as a customer, we continue to select Ansys’ industry-standard tools to accelerate our product design and better inform our engineering choices to provide next-generation propulsion systems for the ultralight and light-sport aircraft aviation industry.”

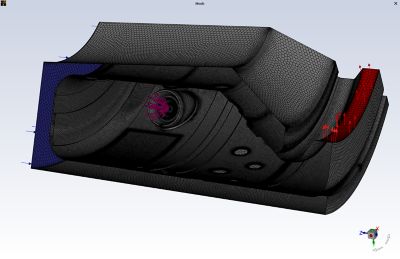

Upon connecting with Ansys, Turbotech quickly integrated Ansys Mechanical, Ansys Fluent, and Ansys CFX into their workflow. Their first development, and most essential to subsequent products, was their signature microtube heat exchanger.

Using Mechanical for structural and thermal analyses, engineers observed temperature and pressure. The team identified values for the strain and deformation of the heat exchanger to approach design and determine the number of cycles (i.e., each shutdown and start-up of the engine) it could manage in its lifetime. Most iterations were performed in Mechanical to evaluate behavior in strong thermal gradients, while CFX was used to look at tube flow and gauge pressure losses.

Turbotech’s heat exchanger is lighter and more compact than traditional heat exchangers, but it can still recover the heat that is normally wasted in exhaust gases and reinject it into the combustion chamber, leading to significant fuel reduction.

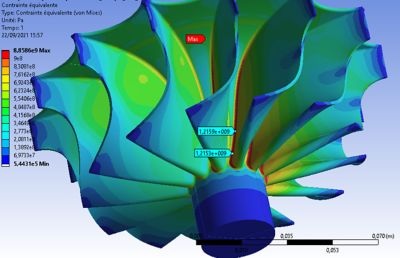

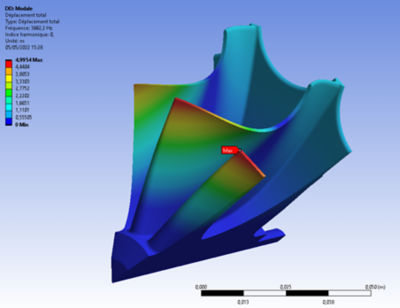

Static structural analysis in Ansys Mechanical illustrates equivalent stress on the turbine wheel rotating at full speed.

Based on this technology, Turbotech developed the first regenerative turboprop with the TP-R90 model, capable of up to 136 horsepower, and the first turbogenerators equipped for hybrid-electric aircraft with two models, the TG-R55 and TG-R90, for 55-kilowatt and 90-kilowatt continuous running power, respectively. The turboprops are suitable for small planes, helicopters, and unmanned aerial vehicles (UAVs), also known as drones, while the turbogenerators are fit for hybrid planes and hybrid electric vertical take-off and landing (eVTOL) aircraft.

Building the turboprop prototype first, engineers used Mechanical to perform harmonic analyses of vibration that could impact the turbine engine or its components, including the gears, shaft, compressor, and turbine wheels. Applying CFX and its built-in tools for blade design, aeromechanics, and turbulence modeling, the team examined aerodynamic components from pressure losses in the combustion chamber to wheel rotation. For the turbogenerator, the group followed the same design, adding a direct drive electrical machine instead of a gearbox to deliver high power density.

Other considerations in turbomachinery design include longevity and time between overhauls (TBO), which is the manufacturer’s suggested number of running hours before an aircraft engine or other component requires overhaul. Both Turbotech’s turboprop and turbogenerator have an impressive TBO of 3,000 hours.

Simulation allows engineers to determine these measurements and combat two of the top ways that turbines deteriorate: oxidation and fatigue. Temperature control is key to prevent oxidation while further thermal analysis helps understand cyclic loading to prevent fatigue and determine TBO and the number of cycles it can endure.

“With Ansys Mechanical, we can get to those values quite precisely and know that we can trust those values because Ansys models are known for their precision,” says Guillaume Malet, a design engineer at Turbotech. “Further, reality and experience confirm the values that we extract from the software, so once we know the fatigue characteristics and the maximum alternate strain of our materials, with the Ansys models we can design the parts properly to meet that and know that we have a design that is robust and can live up to that number of hours or cycles.”

Ansys Fluent is used to visualize thermodynamics such as adiabatic wall model temperature plots inside the combustion chamber.

Powering a More Efficient Future

By integrating Ansys’ simulation, Turbotech accelerated product development by five times, completing each product’s prototype in about two years. The considerable time savings, added with Ansys’ support, resulted in parallel cost savings.

“Ansys’ simulation and the Ansys Startup Program helps us to save time and money because some years ago, people would have needed dozens and dozens of prototypes, but we have been able to have our products running efficiently and smoothly after just a few prototypes,” says Malet. “Without Ansys’ simulation tools, if we had to design test rigs for every component, it would take up to 10 years to be able to run this kind of engine efficiently and smoothly.”

An earlier turboprop prototype experienced repeated high cycle failure. Using static analysis to observe deformation, the team discovered that vibration was the cause and simulated how trimming the blade could reduce or eliminate the issue. The updated design was assembled, tested, and began running successfully within a month.

Today, Turbotech is optimizing their products even further with hydrogen to power a new line of products, BeautHyFuel. The line’s first product is a turboprop designed to run on hydrogen and support on-board cryogenic storage.

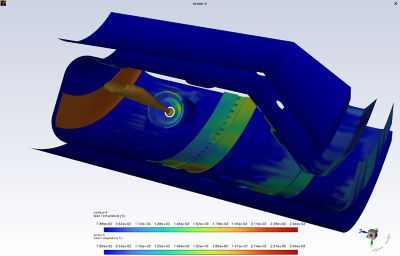

Mosaic poly-hexcore mesh of the combustion chamber and discrete phase modeling (DPM) of kerosene injection simulated using Ansys Fluent

To redesign the turboprop for this use, the team implemented Fluent and CFX to model the droplet flow of kerosene combustion and establish a baseline for behavior and temperature. Next, they altered its injection system and combustion chamber. They also reduced computational time significantly by using the meshing capabilities in Fluent. The group will use the same methods to modify their turbogenerator. Turbotech will continue to offer their original lines, which run on kerosene or sustainable aviation fuel, but will offer the newer hydrogen-powered products in the next few years for customers seeking even more efficiency.

Still, according to Malet, there is more to efficiency than fuel, emphasizing that aerodynamic design and precise engine installation are equally important to create a favorable power-to-weight ratio. For example, a diesel engine could run efficiently in terms of fuel, but could weigh 700 pounds and require frequent overhaul, reducing longevity, and require a heavy cooling system. For this reason, Malet maintains that efficiency needs to consider lightness, robustness, and reliability in addition to fuel.

Fluid temperature contour plot on the kerosene injection plane simulated in Ansys Fluent

Future Flights

As Turbotech soars higher into next-generation aviation technology, they are taking Ansys’ simulation with them. In another upcoming project, Turbotech plans to integrate Ansys’ electromagnetic tools to design a highly optimized electrical machine to power the turbogenerator.

“You need the right simulation tools to get the most optimized design, and without Ansys, we would never have been able to design a compressor wheel with high aerodynamic efficiency and know how it could behave in terms of vibration,” says Malet. “The biggest challenge is to get an efficient, user-friendly tool to help you with your design. Once you master the theory, then you get into practice, and you need the proper tools to help you.”

To learn more, visit the Turbotech website. Learn more about the Ansys Startup Program here.

Total displacement plot from modal analysis on a sector of the turbine wheel shown in Ansys Mechanical