-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

February 14, 2023

Toshiba Speeds Up the Verification of Automotive Semiconductors with Simulation, Model-Based Development, and Digital Twins

Due to electrification, automotive equipment becomes more complex each year. To meet technology demands, equipment manufacturers are promoting simulation-driven development to gain predictive design insights, shorten production time, and reduce prototyping costs.

When working with the electrical components and circuitry of automotive systems, it is particularly important to accurately simulate heat and electromagnetic interference (EMI), the two most critical characteristics related to system reliability. Yet, to simulate these characteristics most effectively, it is first necessary to incorporate accurate semiconductor device models into the system, which typically requires lengthy analysis time.

By integrating Ansys Twin Builder, Toshiba Electronic Devices & Storage Corporation developed a solution to streamline this process by creating Accu-ROM, a model-based development (MBD) technology. Accu-ROM pairs with digital twin technology to accelerate the simulation and verification of thermal and EMI characteristics when semiconductor devices are integrated into a system.

The new technology, which is embedded in Twin Builder, eliminates unnecessary calculations to reduce simulation time by nearly 90% and accelerate verification time by a factor of six.

A Joint Effort: Simulation and Digital Twins

Toshiba has a wide range of semiconductor products that are essential for the electrification of automobiles, with a main focus on automotive inverters, battery management systems, and motor drives. Applications for these products include electric power steering (EPS), electric water pumps, and fans for electric air conditioning.

Browse dozens of automotive products and applications at Toshiba.

Historically, Toshiba engineers verified models of semiconductor elements and substrates as stand-alone units, but verification grew more challenging when these components were mounted in an actual system. They wanted to alleviate this burden and provide customers with reference models of entire systems, including substrates and heatsinks, rather than just models of semiconductor devices as stand-alone units.

The team believed MBD technology could provide a solution for such design challenges while also accelerating verification prior to making prototypes. To develop Accu-ROM simulation technology, Toshiba selected Twin Builder, an open solution that enables engineers to create simulation-based digital twins using hybrid analytics, a set of machine learning (ML) tools that combine physics and data.

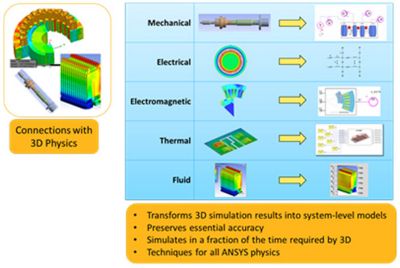

The reduced-order model (ROM) function in particular enabled the team to generate models with reduced dimensions based on results solved with other Ansys tools. Further, the ability to easily connect these models to Twin Builder was an important piece in achieving system-level simulation.

“Ansys Twin Builder met our requirements for solving our problem in that it can be used in conjunction with other Ansys tools to build system simulations that take electrical, thermal, and mechanical elements into account, and it can read common formats such as Simulation Program with Integrated Circuit Emphasis (SPICE) and Very High Speed Integrated Circuit Hardware Description Language for Analog and Mixed Signals (VHDL-AMS),” says Motochika Okano, Ph.D., Fellow of the Package Solution Technology Development Department in the Center for Semiconductor Research & Development at Toshiba.

Twin Builder uses reduced-order models (ROMs) produced from Ansys structural, fluids, electromagnetics, and semiconductor products to model a wide range of applications, including mechanical assemblies, thermal networks, electromagnetic actuators, and signal integrity.

The team also relied on Twin Builder to design EPS systems in a similar system-level approach. When verifying elements using conventional methods or single physics simulations, designs tend to be narrow, focused on very specific conditions, and verified within that margin.

Alternatively, by using multiphysics simulation at the system level, multiple elements such as electrical and mechanical systems can be simulated at the same time. This means that verification can be performed in real time under the loads that occur in actual operation, which enables greater optimization.

Still, simulations that incorporate a variety of elements require longer analysis resulting in longer design and verification timelines, but Accu-ROM uses a MBD approach to streamline the verification process.

Hot Topics in Automotive Verification and More

Unlike Toshiba’s earlier technology, Accu-ROM calculates mechanical components and electronic circuits separately by first verifying the mechanical components, then simplifying the model for mechanical components. Next, the technology verifies the entire system, including its electric circuits. This approach eliminates time-consuming calculations of unnecessary mechanical components during verification.

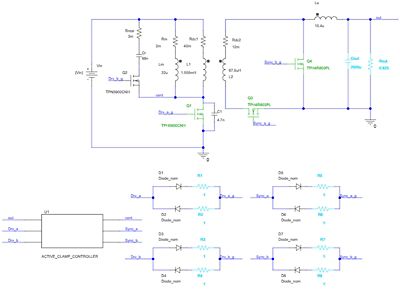

This diagram, available in Toshiba’s Switched Mode Power Supply Library, depicts a SPICE Model of an active-clamp DC/DC.

By evaluating the electric circuits separately, the model automatically generates a VHDL-AMS model from the SPICE model. Using the VHDL-AMS model, engineers and designers can limit the verification range to essential parameters such as heat and EMI noise, which streamlines the verification process.

As such, Toshiba encourages Accu-ROM to support the development of high heat-dissipation and low-noise automotive semiconductors, making it easier for customers to use Toshiba’s products and verify systems. Accu-ROM can also be beneficial for semiconductors in other applications, including home appliances and industrial equipment.

Regardless of application, the technology will help engineers and designers across industries simulate heat and EMI in a short time and with high accuracy for system-level optimization, including electrical, thermal, and mechanical components.

“Simulation helps us develop higher-performance products,” says Okano. “In addition, by developing simulation models for MBD and providing them to our customers, they can significantly reduce the time and cost of validating our products. As a result, we believe we have improved the attractiveness of our products from a business perspective.”

Toshiba engineers have reported significant results using Twin Builder and Accu-ROM technology, including a 90% reduction in simulation time for system operation and a decrease in verification time from 30 days to five days.

Steering Ahead with Insight

Twin Builder uses ROMs produced from Ansys’ structural, fluids, electromagnetics (EM), and semiconductor products to model mechanical assemblies, EM actuators and machines, circuit and cable parasitics, thermal networks, and signal integrity. ROMs can also be imported from a variety of third-party tools.

“Ansys has tools that can accurately simulate various physical phenomena such as electrical, thermal, and mechanical systems, and the characteristics obtained with these tools can be integrated into a single system for simulation,” says Okano.

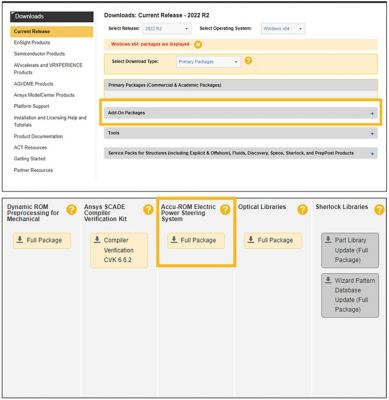

Accu-ROM can be accessed through the Ansys Customer Portal via Downloads > Current Releases.

To install Accu-ROM in Twin Builder, head to the Ansys Customer Portal and select Downloads > Current Release > Add-On Packages > Accu-ROM Electric Power Steering System.

Discover Twin Builder by requesting a free trial here.

Follow Toshiba on social media via: @ToshibaSemi_GL and @ToshibaSemi_JP.