-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

December 22, 2021

The Hidden Delays of the Job Submission Queue

After your engineers have turned their simulation jobs over to the HPC processing queue, where exactly are they? When will processing be finished? And will you make your product launch deadline?

As products become smarter, more autonomous, and more digital in nature, engineering simulations are also becoming much more complex. Leading product development teams are applying multiple physics and analyzing their sophisticated product designs as an integrated system, to avoid late-stage surprises, warranty claims and product recalls.

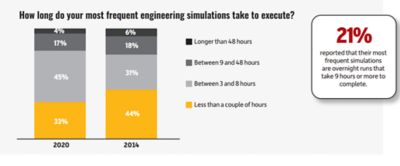

Engineering simulation software has significantly improved in its depth, breadth, and speed, but processing times can still be long for numerically large product simulations. In a recent study conducted by Ansys and Digital Engineering, 21% of respondents said their most frequent simulations take at least nine hours to complete. Another 45% reported that their typical simulation run time ranges from three to eight hours.

Time simulations take to run, according to a study by Ansys and Digital Engineering

High-performance computing (HPC) resources certainly help engineering teams master this challenge, by distributing complicated problems across multiple computing cores for shorter overall run times. Most engineering teams relying heavily on simulation leverage some form of HPC cluster, whether that means on premise or in the cloud.

Simulation Runs Get in Line

However, these shared HPC resources are often overwhelmed. With multiple nine- and three-hour jobs lined up to use the same processing cores, average simulation times can easily double or triple once wait times are factored in. Worse, once jobs are sent for processing, there’s no visibility. Engineers don’t know where their jobs are, where they stand in the queue, or when results can be expected. When a simulation is completed, or if there’s an issue during processing, there’s no way to tell without logging in at all hours of the day.

This may sound like a minor inconvenience, but it’s a major competitive disadvantage ― because it’s costing companies time and money. Not to mention slowing down their ultimate product launch schedules. Hours, days, and even weeks may be lost to the abyss of the HPC job submission queue, as all those wait times accumulate.

Why not simply add more processing cores? Because IT wants to see a high rate of utilization, which translates to a high return on investment. Underutilizing a cluster of expensive computing resources is every executive’s nightmare. So virtually every engineering team, even at the largest companies, has to contend with a long job submission queue.

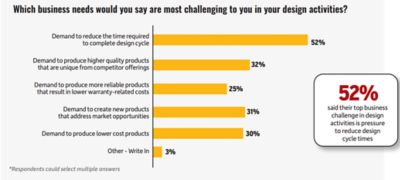

Engineering challenges, according to a study by Ansys and Digital Engineering

In the survey conducted by Ansys and Digital Engineering, 52% of participants said their primary business challenge is reducing design cycle times. In today’s market of extreme innovation, fast-changing market needs and increasing global competition, every moment counts. And your engineers are spending too many moments waiting for their HPC jobs to process, with no idea when they can expect results. That lack of insight is actually the biggest challenge, because your team can’t make intelligent decisions.

Ansys Minerva: A New Level of Visibility and Control

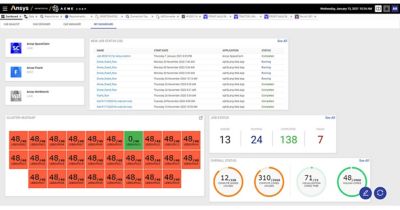

If you’re looking for better visibility and control of your job submission queue, then the wait is finally over. Ansys Minerva ― an enterprise-level simulation process and data management (SPDM) solution — is designed to optimize the everyday work of engineering teams as they leverage the power of simulation, including HPC job submission. Minerva features a single, dedicated user interface that makes it fast and seamless for simulation users to create and submit jobs, monitor their status in real time, and understand the ETA of their final results.

With Minerva, engineers can see upfront how loaded the HPC cluster is, estimate their total wait/run times, and make informed decisions. Working collaboratively, the product development team might visualize the queue and make strategic choices about when, and in what order, to submit jobs to keep the shared launch schedule on track.

Ansys Minerva provides a high-performance computing queue dashboard, proactive alerts, and traceability.

As soon as a given job is completed, or if there are any issues, Minerva sends a proactive alert so users can quickly move on to the next step. After a simulation, users benefit from a visualization of the simulation workflows, traceability for all data, and an automatically generated report that includes all the results files, including 3D images. Everything related to the simulation is captured and shared in a centralized location, instead of being saved locally.

The entire product development team can work more productively, and with more control, to master the challenge of the submission queue. And Minerva tracks and monitors cluster usage, so the IT team can make fact-based, cost-effective decisions about when to add HPC capacity.

Move to the Front of the Line Today

How many of your best ideas are stuck, right now, in the HPC job submission queue? All that inefficiency is slowing your launch times and ultimately costing you revenues. If you’re ready to stop waiting, and start improving your product development speed and efficiency, then why not request a demo of Ansys Minerva today? There’s no better time to start maximizing the value of your human resources and HPC investments by using both more effectively.