-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

October 14, 2022

High Schooler Simulates Backpack Body Stress for Science Fair Honors

While most ninth graders were trying to settle into high school last fall and learn their schedule, one student at the Proof School in California had other concerns.

Anish Sarkar began his school year with one thing on his mind: backpack body stress, which he considers “a silent epidemic.”

Sarkar hoped to alleviate this book-filled burden and prevent injuries by understanding how to carry the load most appropriately. His research would analyze which type of bag — e.g., a regular backpack versus a messenger-style bag — provided the least amount of stress on the back and shoulders while examining which strap positions offered the most support.

Sarkar needed a safe and accurate way to explore all the scenarios and turned to Ansys simulation to conduct virtual testing.

His project, titled “Impact of Heavy Loads on the Human Backbone,” not only concluded the safest way to wear a backpack, but also landed him second place at the 2022 Golden Gate STEM Fair in California, which welcomes local science, technology, engineering, and mathematics (STEM) students in grades six to twelve.

The Backbone of the Project

How would you know if the backpack you wore daily was damaging your back? This was Sarkar’s most pressing question and the inspiration for his project. First, he surveyed people’s preferences regarding which type of backpack they wore and how they wore it. Some chose a traditional book bag wearing both straps, some preferred only one strap, while others liked a messenger-style bag, which bears a single cross-body strap. With this information, Sarkar knew the scenarios he wanted to test but needed a practical way to test them.

That’s when his father introduced him to simulation and explained how it could help him determine the stress of a backpack on the body, without having to physically test all the scenarios.

Sarkar accessed Ansys software through the Ansys Academic Program, which supplies students, universities, and researchers with software and free resources for research and learning.

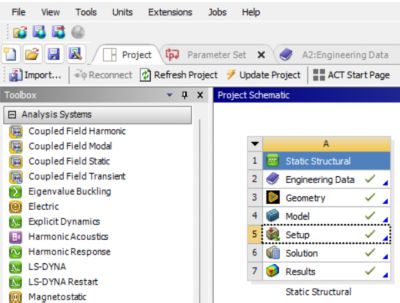

Through the Ansys Workbench simulation integration platform, he accessed Ansys Granta MI Enterprise material data management software, Ansys SpaceClaim 3D computer-aided design (CAD) modeling software, and Ansys Mechanical structural finite element analysis (FEA) software.

“I focused on FEA modeling as a solution to perform virtual simulations,” says Sarkar. “I did not do physical testing, like wearing a heavy backpack and walking a mile with it, because that would have been too time consuming and inaccurate. Even though Ansys Workbench is a complex tool used by professional engineers, I decided to use it because it is faster, more accurate, and versatile than physical testing.”

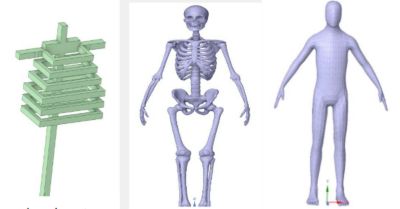

Sarkar used three base models to prepare his simulation: a basic model that he created with Ansys SpaceClaim (left); a skelton model he found online (center); and a muscle-only human body model he also found online (right).

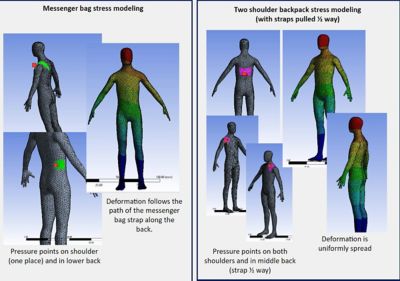

Using the results from his survey, Sarkar simulated the effects of wearing a traditional backpack and a messenger bag, incorporating variables for the weight of the backpack ranging from 10 to 30 pounds. He also added parameters for the length of the shoulder straps, if both or one was used, and for the traditional backpack he examined if they were tugged down, halfway, or not at all. In other words, how the backpack wearer pulled or positioned the straps either by hand or by tightening strap belts. He referred to these three levels as high strap, middle strap, and low strap, respectively. The shoulder strap levels represented where the backpack ultimately rested and applied the most pressure.

Sarkar used three models for his simulations: a basic spine and ribcage model that he created using SpaceClaim and two models he found online of a skeleton and a muscle-focused model of the human body.

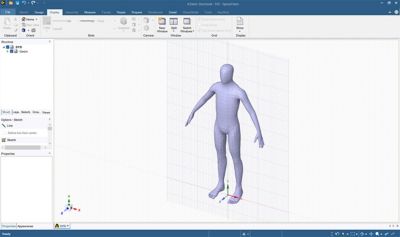

Sarkar refitted each of his three models using SpaceClaim, then generated mesh for each using Ansys Mechanical.

After refitting the online models using SpaceClaim, he generated a mesh for each of the three models in Mechanical. Next, he added pressure points to each model to indicate where the pressure and weight of the backpack was present for each scenario. The location of the pressure point changed for different backpack types and strap lengths, while the amount of pressure changed for different backpack weights. He used Ansys Granta MI to set up the organic material properties for the simulations.

After refitting basic models in SpaceClaim, Sarkar used Mechanical to apply pressue and analyze overall deformation.

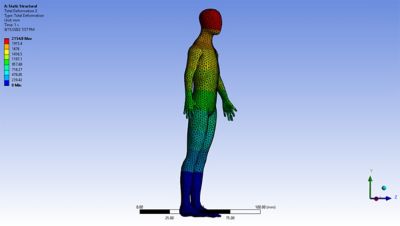

Back in Mechanical, he analyzed the overall deformation of the model after the pressure was applied. This was represented in two ways: numerically and in color. The numerical representation helped Sarkar determine if the scenario was practical or not.

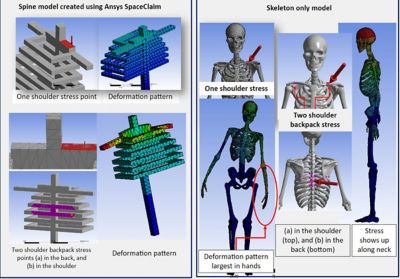

Simulation results in Mechanical and deformation on spine models refitted in SpaceClaim.

For example, if the deformation value was large, then the real-life scenario would cause back pain for the person. The color representation was for visualizing the deformation on the model.

From Sarkar’s simulation results, it was clear that wearing a traditional backpack on one shoulder exhibited the most deformation. Likewise, he concluded that using a heavy messenger bag is also unhealthy unless the bag is light.

For wearing a traditional backpack with both straps, Sarkar concluded that pulling down on the straps all the way (what he deemed as the “high strap” level) produced the worst deformation on the body as doing so causes pressure to accumulate onto the upper body. This pressure can cause a person to lean forward and if a person consistently does this, over time they may lean forward even without their backpacks due to “muscle memory,” which can cause long-term effects.

Generated mesh and resultant deformation on muscle models in Mechanical.

Sarkar determined that the healthiest choice is to wear a backpack on both shoulders at the “low strap level,” i.e., without pulling, positioning, or tightening the shoulder straps downward so the pressure and weight of the backpack sits loosely at the lower back instead of the upper or middle back.

Further, Sarkar concluded that backpack weight should be between 10-20 pounds, depending on body weight, to apply the least stress as deformation significantly increased when weight exceeded 20 pounds.

Finite Element Analysis Gets Results

Sarkar did experience some snags during his analyses. However, these challenges gave him real-world experience with how to resolve FEA issues such as selecting better mesh settings and refining the size of the elements.

Once his project was completed, Sarkar submitted it to the Golden Gate STEM Fair and won second place. As a high-ranking winner, he also participated in the California Science and Engineering Fair.

The use of simulation, Sarkar says, not only accelerated the project, but enabled it.

“For this project, without simulation, I wouldn't be able to understand if the strain and pressure is just on the surface, if it goes deeper inside the body, or if the posture is being altered,” he says. “I would need to spend weeks and months for physical testing then longer to understand if there were long lasting effects, which would definitely strain my body and exert pressure on myself. Virtual testing using simulation makes things possible and safer.”

While Ansys simulation is known for its speed and accuracy, it was the easy-to-use interfaces that stood out most to Sarkar, he says. In Workbench, he appreciated that the simulation features were laid out in a list, requiring just a click to access and navigate next steps. He also found Mechanical user-friendly and especially liked the detailed animations in post-results, which he could observe in motion.

Sarkar appreciated the user-friendly interface in Workbench, which clearly labeled features and enabled him to easily select options for next steps.

“I have not used other simulation software packages, but I definitely liked how Ansys simulation has a lot of features, but is quite straightforward for a beginner like me,” he says.

To take his learning even further, Sarkar contacted the Ansys office in Pune, India this summer while traveling.

He discussed FEA in deeper detail with engineers and also explored the Ansys Learning Hub and Ansys Innovation Courses. Intro to Python, an innovation course about scripting, piqued his interest so much that he would like to learn how to create an application to monitor healthy backpack habits using exported simulation data.

“The courses are quite detailed and I was able to get a lot of advice from the engineers and ask them questions, which is really helpful to get their perspectives,” he says. “I was also able to speak with engineers who worked with different software packages and ask them how the software works, where the benefits are, and what they do.”

Standing Tall for the Future

Looking ahead to college and a career track, Sarkar is most interested in the biomedical field of engineering due to his academic interests combined with his personal experiences.

“I’ve used hearing aids daily since kindergarten and over the years I’ve used some pretty old hearing aids that had issues or weren’t really helping, but some have come pretty far and even have Bluetooth now,” he says. “So, if I were to look at the future, I would definitely like to focus on making biomedical products that can help others by learning how the products are tested to be up to specific quality and what can be done to improve them. Simulation is definitely really helpful to understand this.”

Visit the Ansys Academic page to learn more about Ansys student incentives and browse additional resources, including Innovation Courses and the Learning Forum.