-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

December 11, 2023

Rolling Toward a Different Future with Simulation

How a model-based, simulation-centered systems engineering approach will help truck manufacturers transcend rapid industry transformation

The trucking industry is experiencing growing pains exacerbated by rapid transformation. This transformation is fueled by the push for electrification, increased connectivity, and the demand for autonomous operation. Consequently, trucks must make the shift from diesel to battery or fuel cell power, requiring unique software-based powertrain and energy management systems. Shaped by digital logistics, customer requirements, and system interfaces, they’re also becoming highly interconnected, interdependent, software-powered edge devices. And, despite the absence of enthusiasm for self-driving semis, the shortage of drivers will eventually necessitate the need for fully autonomous transport.

In light of rapid industry advancements, how will truck manufacturers, component and system suppliers as well as engineering service providers remain relevant? According to the Berylls Group, to effectively navigate these challenges requires agile development methodologies leveraging digital technologies for simulation and virtual prototyping, all supported by enhanced collaboration.

Berylls, a strategic consulting company, recently published "Beryll’s Strategy Advisors: Model-Based System-Engineering in Trucks R&D,” a discussion that connects the evolution of software-defined vehicles (SDVs) with the need for model-based engineering solutions to facilitate SDV development. The following draws from these findings, including the role simulation plays in facilitating sound MBSE strategy in the development of SDVs in the trucking industry.

The Pressure to Innovate While Navigating Complexity

Transportation and logistics facilitate the movement of goods around the world — activity essential to production and consumption. The exponential growth of e-commerce highlights the need for fast, reliable transport. To this end, in 2021, approximately 3.4 million medium- and heavy-duty trucks were manufactured globally. In the future, this number is predicted to grow as these vehicles make the transition to electrification via battery or fuel cell powertrains. Naturally, with this push also comes massive pressure to speed innovation.

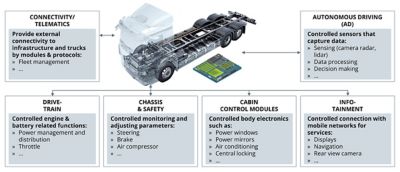

Current electrical/electronic (E/E) truck architectures, however, require a great deal of complexity during development. They are characterized by multiple electronic control units (ECUs), which play a critical role related to embedded software, as they control various vehicle systems and process sensor data. In fact, as many as 120 or more ECUs are required to regulate hundreds of functions in a modern truck, process data from sensors located throughout the vehicle, and make decisions based on that data.

Vehicle functions controlled or provided by ECUs. Source: Berylls Strategy Advisors

Additionally, the related embedded software is developed from scratch to run on that hardware in a precise configuration involving the coordination of complex algorithms to ensure timing functions, coordinate inputs and outputs, and maintain data security. A shift on the part of research and development (R&D) organizations is needed to address these functionalities. This helps original equipment manufacturers (OEMs) better align personnel, processes, and technologies that support successful connected SDV development — saving time, reducing costs, and minimizing quality issues during software development.

Boosting the contribution of this embedded software are the advanced driver-assistance systems (ADAS) it supports. Investment in ADAS is mission critical for OEMs as they lay the fundamental groundwork for the development of advanced perception, decision-making, and motion control systems that will drive autonomous function in the future.

Adding Value Into the R&D Toolchain with MBSE

To reach new developmental milestones — including those tied to architecture, hardware, embedded software, and perception system development — will require significant spending in R&D. It is predicted that vehicle manufacturers will increase investment in E/E tech by 64% over the next 10 years, with software accounting for the majority of this spending.

In today’s manufacturing climate, accelerating innovation cycles increases demands for specialization and often results in outsourcing the development process. Rarely do truck OEMs work in isolation to bring truck platforms to market with any success. Instead, the development process involves bringing outside, often disparate entities together, including the OEM, tier one supplier, and outside experts. This can drive complexity in value creation that leads to quality issues or failure. Therefore, truck OEMs are choosing MBSE to take an integrative approach on R&D value creation, involving faster and more integrative development cycles using a state-of-the-art toolchain.

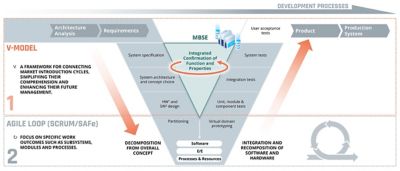

MBSE is a methodology that focuses on creating and exploiting digital system and engineering domain models as the primary means of exchange of information, feedback, and requirements. It involves the entire process of capturing, communicating, and making sure that all digital models used to represent a system are coordinated and maintained throughout the entire life cycle of that system. It also replaces static documents with comprehensive digital models that represent key aspects of a system, including requirements, architecture, and system interfaces — all connected by a digital thread that traces an entire design.

Essentially, MBSE offers a structured, systemic approach to solve complex engineering problems, thereby streaming the development process and increasing efficiency. It involves three major components: the overarching system architecture model (SAM), engineering simulation software to determine SAM requirements, and a centralized computation center to perform the functions and store the results of MBSE processes.

MBSE exceeds the V model and closes the loop. 1 HW: Hardware 2 SW: Software Source: Expert Interviews, Berylls Strategy Advisors, Fraunhofer IPK

Simulation as a Key Value Driver in MBSE

MBSE’s successful implementation holds great promise for the trucking industry in meeting its most pressing challenges as they are expressed through design, electrification, and automation. Taking a system-oriented development approach simplifies responsibilities among key stakeholders.

It also reduces efforts through the coordination and division of subsystems, as well as the delegation of hardware and software components and functions to that system. When adapted to OEM’s organization, processes, and tools (OPT), this effort, with the oversite of a project manager, streamlines processes and increases efficiency.

There are several ways simulation can play an outsized role in truck manufacturing as it is expressed in an MBSE approach to boost development and uncover efficiencies all along the development chain:

- Through testing and validation, simulation acts as part of MBSE’s interdisciplinary approach to analyzing all the relevant aspects of system architecture, such as mechanical, electrical, and software and control systems, which in turn illuminates system functionality and interactions.

- Simulation enables systematic modeling of the system, subsystems, assemblies, and model components that enhance reusability across different products and systems, which drives greater efficiency and manages redundancies while reducing development times and costs.

- Creating digital twins or virtual representations of physical systems helps OEMs consider wear and degradation models in a virtual environment, leading to insights that can increase fleet operational efficiency and prognostics and health management (PHM), as well as reduce downtime and assess part repurposing/reusability.

- Functional hazard analysis, fault tree analysis (FTA), and subsequent system safety analysis (SSA) via simulation makes it possible to evaluate safety and reliability from multiple perspectives, from the architectural and system levels down to the individual components.

These are just some of the ways simulation can support transformational change in the trucking industry. In light of an ever-evolving commercial vehicle industry, it is critical for manufacturers to pursue simulation-driven R&D approaches like MBSE to manufacturing and project management that address the complexity of these challenges in ways that positively impact performance, efficiency, and cost during development.

For more information, read "Beryll’s Strategy Advisors: Model-Based System-Engineering in Trucks R&D” on the relevance of MBSE to solve large development issues facing the trucking industry. You can also discover how simulation fits into a comprehensive MBSE approach.