-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

October 7, 2022

Optimize Radio Frequency Filter Design with SynMatrix and Electromagnetic Simulation

As wireless connectivity rapidly advances beyond 5G, the demand for radio frequency (RF) filter components in millimeter-wave (mm-Wave) frequency bands is higher than ever.

RF Filters Design Basics

RF filters are essential to a wide range of devices and applications, including broadcast radio, amplifiers, television, and wireless communications such as cell phones. Essentially, RF filters are the passive components that act as gatekeepers. They eliminate unwanted signals, frequencies, and noise that would otherwise cause interference or potential damage to the product and how it is intended to function.

Types of RF Filters

- Low pass: allows signals with a frequency lower than a selected cutoff frequency and filters signals with frequencies higher than that cutoff frequency.

- High pass: allows signals with a frequency higher than a certain cutoff frequency and filters signals with frequencies lower than that cutoff frequency.

- Band pass: allows frequencies within a certain range and filters frequencies outside of that range.

RF filters have an important role in overall product function and connectivity, so accurate RF filter design is critical, but the process can be challenging and require multiple disconnected tools.

SynMatrix Technologies Inc., an Ansys technology partner, offers a solution through an all-in-one RF filter design and test tuning software platform that can be paired with Ansys HFSS 3D high-frequency electromagnetic (EM) simulation software to reduce development time, material and operational costs, design risks, and product failure.

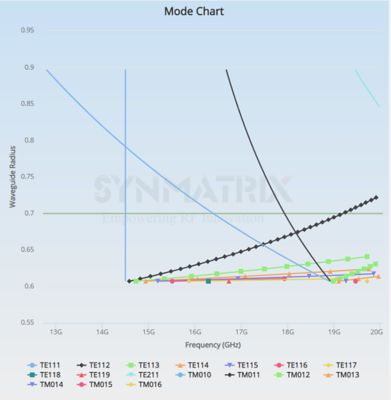

A mode analysis chart helps select the best radio frequency filter design. Image courtesy of Synmatrix.

Overcome RF Filter Design Challenges with Synmatrix

According to SynMatrix’ founder Diamond Liu, one of the top challenges in RF filter design is the uncertainty surrounding EM phenomena, but the SynMatrix and HFSS workflow provides insight, confidence, and accuracy.

To develop the sophisticated workflow, Diamond surveyed engineers to understand the pain points of previous RF filter design methods. The two aspects that were the most time consuming were 3D modeling — especially to customize designs — and optimization.

By integrating simulation with RF design filter software, the workflow becomes more intuitive and designs can be achieved more speedily, affordably, and accurately.

“Engineering time is very valuable and saving meaningful engineering time by using this workflow lowers the cost,” adds Diamond. “Without this workflow, the process would take a long time and have more uncertainties, which is why the optimization is quite important.”

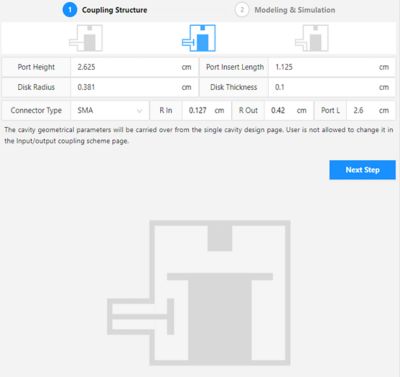

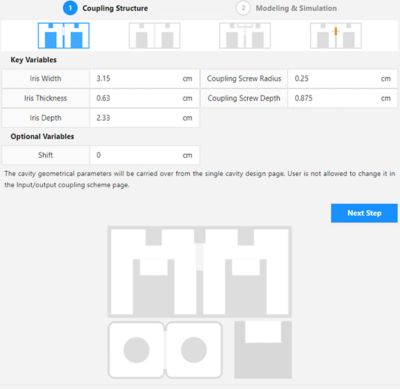

Input-output (left) and coupling schemes (right)

The RF Filter Design Process

The SynMatrix and HFSS workflow streamlines the RF filter design process in three steps:

- Create the design goal using powerful SynMatrix synthesis tools and built-in algorithms.

- Build the 3D model in HFSS using SynMatrix automated layout tools.

- Import the 3D model back into SynMatrix and then start optimization.

SynMatrix offers a powerful platform for filter specifications development that includes a comprehensive topology library, dispersive functions (used to predict dispersive impactions), matrix optimization, Monte-Carlo analysis, and coupling matrix synthesis.

On the simulation side of things, in addition to its known accuracy, SynMatrix offers multiport tuning, deep optimization, and advanced coupling matrix extraction.

“The purpose of this pairing is not just realized automation,” Diamond says. “Automation, of course, is good but the most important thing is how this pairing can provide users with the simplest way to achieve their design goals.”

Other challenges in RF filter design include power spikes and temperature drops. Power spikes are related to power handling capabilities and are one of the most important parameters to consider in visualizing future behavior. This is especially true for filters that use transmitters, which require a great deal of power that could potentially cause a system breakdown.

The two main types of breakdowns are vacuum breakdowns, mostly seen with satellites, and ionization breakdowns, which are gas breakdowns that are common with ground-based stations. The SynMatrix and HFSS workflow helps analyze the latter with ionization breakdown analysis.

To understand peak power handling capabilities, designers typically need to run mathematical formulas to determine a breakdown threshold while accounting for unknown environmental conditions such as altitude, temperature, or frequency. Next, they need to simulate this for a single unit to retrieve data to predict whole structures, including which electrical fields to extract and which energy values to store for both the circuit model and the simulation model.

“Other methods require the user to jump over from different platforms to collect this data,” says Diamond. “But by using SynMatrix the user just needs to click a button for help with calculations or to extract useful data from HFSS, such as the fields magnitude or stored energies.”

Though other platforms may offer automatic 3D modeling workflows, he says, SynMatrix provides generic layout options that allow the designer to build, drag, and rotate elements of their model to customize their design. Unlike other platforms, the SynMatrix workflow will generate a fully parameterized model in HFSS, allowing users to edit and customize their models with even greater design freedom.

“Without this workflow, the user would need to rely on third-party circuit tools to build up the circuit model to represent their physical model and then start the simulations or optimizations with many uncertainties,” says Diamond. “It is also time consuming. Even if you complete the 3D modeling, the optimization is quite a headache. The new workflow can save at least 40% to 50% of engineering time, and for some simple cases it can save more.”

Explore the RF Filter Design Workflow

To learn more about the workflow, view the webinar: Designing Coaxial Cavity and Waveguide Filters With 3D Modeling and AI.

In this session, Diamond Liu demonstrate the accelerated SynMatrix and HFSS workflow for 5G and mm-Wave microwave filter design while highlighting the use of automation. The presentation also features new methods to calculate temperature drift simulation and power peak analysis.