-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

January 15, 2021

Qualup Meets High-Temperature 3D Printing Challenges with Simulation

Qualup SAS has been at the forefront of fused filament fabrication (FFF) 3D printer design and manufacturing since 2011. The small French company specializes in creating 3D printers with heated chambers, which differentiates its products from many hobbyist 3D printers. Heated chambers allow the company’s 3D printers to work with more technical materials than PLA (polylactic acid), the most common FFF material, and branch out into markets like aerospace that require more technical materials.

The Qualup SAS team has almost 40 years of experience designing specialized machines and working with computer-aided design and manufacturing software. Still, creating a 3D printer that could work with PEEK (polyetheretherketone) was a worthy challenge because the material requires a 270 C (518 F) heated chamber to print and cool properly, according to Philippe Boichut, owner of Qualup SAS. Where there’s heat, there are thermal challenges.

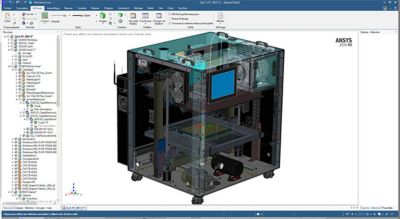

The Qualup Qu3 high-temperature 3D printer

PEEK Inside the High-Temperature 3D Printing Process

PEEK is prized for its mechanical and thermal properties, as well as its chemical resistance. It is one of the highest performing thermoplastics available. PEEK is used in demanding applications in aerospace, automotive, oil and gas, medical and other industries. However, like many materials, it can warp if allowed to cool too quickly as the filament is melted, extruded and layered into a part during the 3D printing process.

It’s not just the effects of temperature on the printing material that are critical. Those high temperatures could also take a toll on the 3D printer.

“Since a printing cycle can last several tens of hours, these printers must be able to withstand very high temperatures for long periods of time,” Boichut says. “The components used in the printer must be able to resist extreme temperatures or be cooled.”

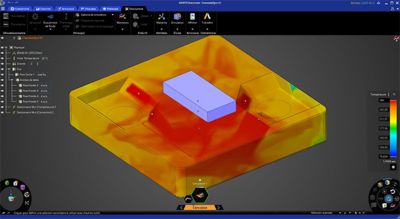

Thermal simulation of internal ventilation chamber

Cooling components and ventilating the chamber is a balancing act because the temperature inside the printing chamber must be maintained as constantly as possible to ensure a high-quality build. This can create a thermal conundrum when designing a 3D printer that relies on mechanical and electronic components.

Qualup meets those challenges with the help of Ansys SpaceClaim and Ansys Discovery. SpaceClaim is used for the complete design of 3D printers and Discovery is used to quickly evaluate the influences of design variations on the print chamber, as well as the influence of the design on the cooling of certain components.

For example, the Qualup Qu3 HT 3D printer has a heated print chamber that can be adjusted from 30 C to 275 C (86 F to 527 F), allowing it to print high-temperature materials such as PEEK, PEKK (polyetherketoneketone) and PEI (polyether imide), as well as more conventional filaments. It features a high-definition camera and a 21-inch screen for monitoring print runs. A high-resolution infrared thermal imaging camera is available as an option for precise temperature control.

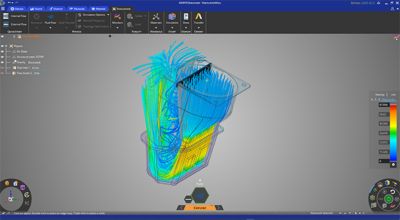

Simulation of ventilation in the ventilated well of the thermal camera

“The cooling of some critical components, such as the IR thermal camera, has been validated on Ansys Discovery,” says Boichut. “A design error in the cooling of this camera was highlighted in 15 minutes. Ansys Discovery gives us the incredible possibility to modify the modeling live and to visualize the effects instantly, a perfect tool for designers.”

Flexible, Agile and Accurate Design and Simulation

From the beginning, Qualup was able to quickly iterate on heating the high-temperature chamber of the Qu3 HT using SpaceClaim. The Qualup design engineering team created several iterations of different solutions in just a few hours.

“With Ansys SpaceClaim you are free,” says Boichut, noting that his team isn’t beholden to a demanding construction tree during the product design phase when using SpaceClaim. “We don't know how other companies design, but for us, we never succeed in designing the right part the first time. Ansys SpaceClaim allows us to change our minds and explore several designs.”

Full assembly of a 3D printer in SpaceClaim

That ability to direct model without constraints is just as flexible whether Qualup is using SpaceClaim files or imported STEP files. Discovery leverages the SpaceClaim architecture, allowing Qualup design engineers to make modifications on the fly. This drastically reduces the time required to validate a design.

For example, Ansys Discovery allowed Qualup to predefine the internal ventilation of the heated chamber in 10 minutes instead of spending weeks making and validating prototypes.

“I've been working with SpaceClaim for several years now. The first time I tried Ansys SpaceClaim, what struck me was the intelligence that has been put into this product – everything is simple, concise, easy – no need to spend hours of training to get the product up and running,” says Boichut. “When Ansys Discovery Live was released, Ansys went even further by adding the ability to simulate physics directly in CAD files without hassle or any overcomplicated commands."

The heated chamber and ventilation solution designed with Discovery Live is still used in the latest version of Qualup’s 3D printer.

“Without Ansys products, we would never have been able to design our new 3D printer in such a short time,” Boichut says.