-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

Ansys Blog

October 26, 2018

Low-voltage Drive Improves the Safety and Performance of Electric Vehicles

Engineers face a significant challenge ensuring the safety of electric vehicles. Traditionally, electric drive systems run on a voltage high enough to seriously harm people.

This means automakers put in a lot of effort to prevent mechanics, autoworkers and those caught in accidents from the risk of touching a live wire.

Volabo’s retrofit of a Touran runs for

200 km on a 48-volt electric engine

Consumers want more from electric cars and the easiest way to improve the power of electric drives is to increase the voltage. This only exacerbates the electric safety problem.

To address this challenge, Ansys Startup Program member, Volabo, offers an electric drive that runs on only 48 volts — a safe-to-touch voltage.

“This is an 8-times — at times, even 16-times — reduction compared to current electrical vehicles on the market,” says Florian Bachheibl, co-founder of Volabo. “At 48 volts, you could hold both the positive and negative terminals while the car is running and not feel a thing. This electric drive is intrinsically safe.”

Volabo’s drive is also more affordable and renders switchable gear boxes and power safety equipment obsolete in electronic vehicles.

How to Make Intrinsically Safe, Low-voltage Electric Drives

Volabo uses an intelligent stator cage drive (ISCAD) system. The setup replaces copper windings — the most expensive part of an electric motor — with affordable and easy-to-manufacture aluminum bars.

“The motor works on the same general concept that traditional electric motors do,” notes Bachheibl. “It transforms current into magnetic flux that creates torque in the rotor.

The ISCAD motor uses solid aluminum

bars — seen protruding through the

bearing shield — instead of windings

to convert electricity into torque

“However, we are better capable of controlling the magnetic field than traditional electric motors. Traditionally, you have three windings so three points to determine the magnetic field. We have 20 to 60 bars and each can be used to alter the field or change the poles.”

Now, any engineer worth their salary can tell you that copper is a much better conductor than aluminum. So, why did Volabo go with aluminum?

Volabo found it could fit more conductor cross-section in the electric drive as they are using straight bars, hence aluminum becomes a possible choice for the conductor material. As a result, Volabo can achieve better conduction overall due to the parallelization from these 20 to 60 bars. In fact, the ISCAD drive outperforms traditional electric drives by 25 percent in terms of drive-cycle efficiency even though it runs on only 48 volts.

This low-voltage drive has a considerable safety benefit. Above 60 volts, engineers need to introduce safety systems into a product. Traditional electric drives run at 400 to 800 volts. So, the safety systems in these vehicles must be robust and remain effective even in catastrophic crashes.

“Volabo’s electric drive, however, is intrinsically safe,” explains Bachheibl. “Therefore, it doesn’t need expensive electronic safety features.”

The Efficiency Savings of Low-voltage Electric Drives

Volabo’s ability to exert control over the magnetic field, while reducing the voltages of its electronic drives, has a lot of benefits for electric vehicle manufacturers.

First, the drive makes switchable gear boxes obsolete as the motor’s variable magnetic field acts as a virtual gear box. Instead of changing gears based on the road conditions, it can control the torque by altering the magnet field.

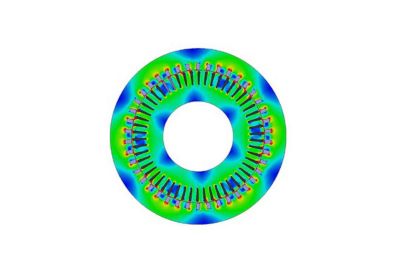

Electromagnetic simulation of the

ISCAD motor using ANSYS Maxwell

“This engine will still need a gear box,” says Bachheibl. “But it will be much simpler and cheaper with a constant ratio of about seven to one.”

The electric drive’s ability to control its magnetic poles also makes it more efficient than traditional electric drive systems.

You hear about electric drives running at 97, even 95, percent efficiency. However, that is at their optimal torque and speed,” says Bachheibl. “Under varying operating conditions these drives can see their efficiencies drop to 70 or even 60 percent when driving in the city.

“Since we can vary the poles of the drive based on the operating conditions, we can consistently run on an optimal setting for the current road conditions. Overall, our studies find our drive is 25 percent more efficient. This means you can drive 25 percent more for a given battery power density.”

The electric drive’s low voltage also opens the door to further efficiency boosts. High-voltage electric drives often use insulated gate bipolar transistors (IGBT). Volabo’s electric drive can get away with metal oxide semiconductor field-effect transistors (MOSFET).

“IGBTs are inefficient at partial loads but are the only option above 100 to 200 volts,” says Bachheibl. “As we are using lower voltage we can use MOSFET. This leads to better efficiency.”

How Volabo Designs Low-voltage Electric Drives

Volabo gains access to the simulation technology it needs through the Ansys Startup Program.

“We design a multiphysics system and each subsystem is intertwined,” says Bachheibl. “To model them all at once, we used Ansys products as they fit so well together: Ansys Maxwell for electromagnetics, Ansys Icepak for cooling, Ansys Mechanical for structures or Ansys Fluent for fluids.

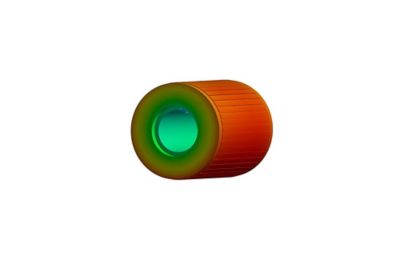

A detailed thermal simulation

on the ISCAD’s rotor

We could couple our domains or take the results from one simulation and use them in another. We profit a lot from that.”

To learn how to gain access to these simulation products, check out the Ansys Startup Program