-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

December 14, 2022

Brrraaap: KTM and Ansys Go Full Throttle on Dirt Bike Electrification

On a dirt bike almost any terrain is fair game. Once you hit the back roads, course correcting through open fields or wooded areas to get where you’re going (or not) is easy. These powerful-yet-agile gravel-and-dirt surfing, rock-hopping machines have been identified by some as the undisputed off-road champions — perfect for exploration in places larger vehicles simply can’t go.

Dirt biking is all about the connection forged on the road, or on the trail between rider and environment. This connection, and the journey to net-zero are evolving the rules of engagement — specifically, what happens when you electrify a dirt bike?

With support from Ansys’ channel partner CADFEM, KTM, a large European motorcycle manufacturer, used simulation to find out just how far it could push the boundaries of e-bike performance and innovation of its street and off-road models in an eco-friendly electric motor and traction battery design.

Simulation Drives Wide-Open Battery Development

Demand for e-bikes is on the rise. They may be more expensive initially, but the high price of adoption is quickly offset by lower fuel and repair costs. As far as performance trade-offs go, electric dirt bikes are essentially lighter, quieter, more agile versions of their gas-sipping cousins that experience more instantaneous, efficient power delivery within a much smaller carbon footprint.

They also require less maintenance — which means more time on-road, or on the trails.

Ansys helped KTM pass all these benefits on to their customers in its electric models currently in development through a simulation-driven design process across numerous disciplines — from structural mechanics and composites to aero- and thermodynamics. And, when ran on a high-performance cluster, KTM was able to successfully develop a more competitive and innovative battery for the electric dirt bike.

Virtual Design Workflows Find Thermal Hotspots

Thermal management of the battery is a central issue in electric mobility. The aim of the KTM team was to implement a scalable workflow that enabled the virtual design, validation, and verification of a traction battery with optimized thermal properties — to maximize range, speed up charging times, reduce aging through temperature distribution, and prevent overheating that can lead to thermal runaway.

Developing a traction battery for KTM’s e-bike design accounting for multiple physics required a departure from the solitary use of various Ansys tools. Normally, separate simulations of temperature fields or flow behavior are sufficient in the initial stages of their pre-development process. However, e-bike traction battery optimization demands simultaneous consideration of thermal hotspot avoidance, temperature distribution, and the best constellation for fast, efficient charging.

“Approaching e-mobility, we were easily able to build on our own expertise in motorcycle development,” says David Singer, simulation engineer for multiphysics, KTM R&D. “We know what matters when you’re constructing a bike chassis and suspension or designing efficient development processes. The added challenge for us involved the design and development of the electric motor and traction battery.”

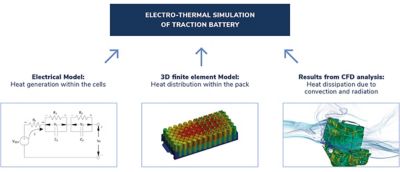

To address these challenges, the KTM team developed a simulation workflow enabled by Ansys Twin Builder consisting of three submodules coupled at the system level — all exchanging input and output data during computation.

An electrical lumped model was used for heat generation per cell as a function of each cell’s temperature and its state of charge (SOC). Resulting values were then fed into a compact thermal model derived from 3D finite element method (FEM) models that calculate the battery’s temperature distribution. A third sub-module was created based on computational fluid dynamics (CFD) analysis to calculate thermal dissipation of the battery housing resulting from convection and radiation.

Model order reduction was performed in Ansys Mechanical via CADFEM extension. Then the reduced order model (ROM) was imported into Twin Builder. The highly specialized tool “Model Reduction inside Ansys,” developed by CADFEM, also enabled reduced order model extraction from Mechanical with significantly fewer degrees of freedom, drastically accelerating computation times without a significant loss of accuracy. Battery pack ROM verification was accomplished using transient simulation of a full 3D model to track the accuracy of and determine the optimal parameter settings for model order reduction in Mechanical.

Coupled complex electrical-thermal simulation.

“Using the Ansys solution, we produced an electrical model based on an equivalent circuit model (ECM) we can employ to compute electrical performance and lithium-ion cell loss as a function of SOC and temperature,” says Singer. “Through experimental testing, we arrived at and extracted the required parameters for all circuit components from the test data. From there we could model the instantaneous and dynamic behavior of the cell to better capture the heat generated by the cells at different temperatures and states of charge.”

Twin Builder’s Battery Wizard Tool Kit Works its Magic

Currently KTM’s R&D cell testing efforts are conducted in-house. What grew out of this requirement was a cell database of all options considered for any given project. Basically, all related test data is measured and recorded during pulse discharges at various temperatures, then incorporated from the database into the Battery Wizard tool kit in Twin Builder, which automatically generates the required ECM lookup tables per cell.

Working within this framework facilitates rapid shifts between different cells in the system model to quickly deliver information that supports the design teams’ decision-making process. Once single-cell ECM tables are created, the wizard can connect cell ECMs in parallel and in series according to pack specification to configure an accurate electrical model for the battery module. In this instance, the ECM module was implemented and coupled in the final Twin Builder system simulation.

Twin Builder’s underlying Python scripting capabilities provided an efficient way to couple models to the appropriate outputs.

When Discovering Battery Pack Stability is Simply a Matter of Degrees

Major effort was also put into the validation of the simulation model against experimental test data. Matching involving both constant current and dynamic discharge measurements enabled iterative validation of the coupled model, from the output voltage of the ECM for a single cell to the predicted voltage and temperature of the entire battery.

In the instance of a single cell, the predicted output voltage showed an error of less than 20 millivolts (mV). For the overall battery pack model, a temperature deviation of less than 2 °C was achieved for certain drive cycles compared to the measured cell temperatures, resulting in a stable battery pack design.

Simulated model (left) of real freeride e-battery pack (right).

Predicting the Future with Electro-Thermal Models

Once fully implemented in Twin Builder, the electro-thermal model of the battery pack could simulate real-world drive cycles and predict data outputs, including peak temperatures and temperature distribution, as well as heat transfer.

“Regardless of model complexity and size, we can now solve computations of hour-long drive cycles in close to real time, while simpler models can take just minutes,” says Singer. “The inclusion of a virtual battery pack also helped our team identify and eliminate potential problems in battery design, including design issues early on in the development process.”

Ultimately it was the accuracy of the predicted absolute values coming out of model analysis that supported more confident decision making leading to better battery pack designs. In fact, these values became an important criterion for determining the air-cooling properties of the battery pack. For example, using a virtual model, the KTM team could evaluate trade-offs between proposed battery pack housing geometries, as well as the design of the motorcycle fairings to optimize air flow.

Getting the Holeshot with Ansys

Today KTM’s longstanding relationship with Ansys and its channel partner CADFEM plays an integral part in KTM’s traction battery development process.

“With more than 10 years' experience using Ansys simulation, our R&D team considers Ansys to be a valuable partner,” says Singer. “In addition to software procurement and hardware, we rely on the support of CADFEM for training, customized workflows, and technical Ansys simulation support, as well as participation in joint projects — all of which give us a huge competitive advantage.”

Wondering how Ansys Twin Builder can help meet your electric motor and battery development objectives? Why not take the tool for a free test drive and see for yourself. Also, a big thanks to CADFEM, who originally captured this story.