-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

June 28, 2022

Intel Foundry Service’s New Cloud Alliance Addresses Customers’ Semiconductor Design Challenges

Industry digitization is increasing the demand for semiconductors worldwide, yet the manufacturing capacity needed to meet that demand is concentrated in one corner of the world. As we’ve seen with recent supply chain issues in automotive and other sectors, this creates significant bottlenecks in chip capacity. As a result, we’re now experiencing unprecedented global shortages of many products that rely on semiconductors — from vehicles to consumer electronics and everything in between. Addressing the disparity requires a more balanced manufacturing approach to deliver a secure, sustainable supply of semiconductors around the globe.

To help meet this demand, Intel Foundry Services (IFS), a fully vertical standalone foundry business, recently announced a cloud alliance initiative that takes advantage of the company’s capabilities and experiences. With support from Ansys and other electronic design automation (EDA) vendors, the new offering will improve customer efficiency, facilitate greater technology enablement, and help meet capacity commitments for IFS customers.

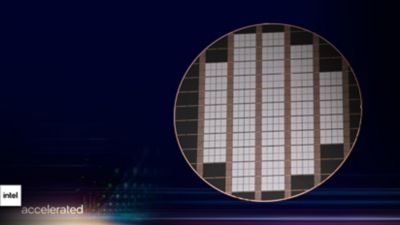

A test package of a wafer level assembly is displayed as part of the "Intel Accelerated" event where Intel presented the company's future process and packaging technology roadmaps. Credit: Intel Corporation.

Ansys Tools Support a Broader Cloud-Based Manufacturing Strategy

Ansys RedHawk-SC™ and other Ansys tools are an integral part of the IFS Cloud Alliance, a cloud-enabled workflow created to enhance their customers’ design process. The workflow is intended to optimize chip designs in alignment with IFS customer service objectives for capacity; early access to leading-edge packaging technologies (including advanced 2D and 3D capabilities); and design enablement through advanced design and IP capabilities.

"Ansys’ comprehensive suite of interoperable, scalable multiphysics solutions plays a key role in IFS’ first design flow supported in the cloud," said John Lee, vice president and general manager of the semiconductor, electronics, and optics business unit at Ansys. "We look forward to continuing our long-standing collaboration with Intel to advance semiconductor design by ensuring that chip designers can access Ansys' gold standard multiphysics solution via the cloud regardless of their chosen EDA workflow."

IFS Cloud Alliance: Expanding on Manufacturing, Innovation and Leadership Strategy

Last year Intel made headlines by announcing IDM 2.0, a strategy for manufacturing, innovation, and leadership. The strategy began with a large investment in support of two new factories — part of Intel’s expansion plans as a way forward to manufacture, design, and deliver products that provide long-term value for Intel’s key stakeholders. In a continuation of this plan, Intel has also committed to this expansion over the next decade in R&D facilities in Europe, the Middle East, and Africa in a move hailed by the European Commission as the first sign of success for its Chips Act. Implicit within these plans is Intel’s desire to position itself as a major provider of foundry capacity in the United States and Europe via IFS and extend its global reach in semiconductor chip production.

The IFS division of Intel offers chip manufacturing expertise to other chip designers. The world leader in semiconductor manufacturing delivers a range of services, from mask generation and wafer fabrication to packaging, assembly, and test services in a single, scalable supply chain solution. In support of these objectives, the company heavily invests in research and development to drive advancements in semiconductor chip technology and support customers with industry-leading platform solutions.

Cloud Computing Enables Reliability, Reduced Costs, and Greater Collaboration

As an integral part of the IFS Cloud Alliance, the open, interoperable, scalable nature of Ansys multiphysics analysis solutions, including Ansys RedHawk-SC, Ansys HFSS, Ansys PathFinder, Ansys VeloceRF, and Ansys RaptorX, enables customers to access Intel’s leading silicon technologies via the cloud to improve efficiencies. The IFS workflow facilitates shorter product design cycle times while simultaneously supporting more innovative, reliable chip designs.

Ansys’ strategic partnership with Intel optimizes the solver performance and scalability of its portfolio to enable faster simulations and speed time to market for customers. As this long-standing relationship with Intel continues to expand, it will provide more opportunities for customers to capitalize on the benefits of cloud computing.

In addition to product design speed boosts, working in the cloud brings globally dispersed teams together on one platform, encouraging greater collaboration, while reducing time lost to stalled communication through other channels. The cloud also negates upfront infrastructure costs and helps slash long-term maintenance costs through outsourcing. All of the inherent benefits of Ansys’ software solutions are integral to the success of this latest Intel initiative.

“We are pleased to announce the launch of the IFS Cloud Alliance to accelerate design on the cloud,” said Rahul Goyal, VP and GM of Intel Product and Design Ecosystem Enablement. “We are excited to have Ansys as an alliance partner, and look forward to continued collaboration with Ansys to enable efficient reliability and verification flows on the cloud.”