-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

May 10, 2022

How to Create a Laser Model for a Photonic Process Design Kit (PDK)

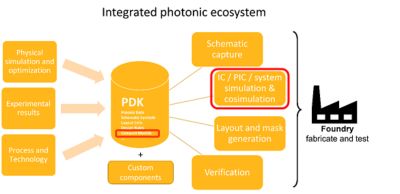

The need for photonics to serve the large demand for data transfer in datacenters and telecommunications is growing. Like in traditional electronics design automation, photonic engineers can design photonic components at the circuit level with an ecosystem of tool providers and fabs to support it. In recent years, the field of photonics has matured to have reliable Process Design Kits (PDK), as shown in figure 1.

Figure 1. Integrated photonic ecosystem with the process design kit (PDK) at its center. PDK stores information about process, schematic symbols, layout cells, design rules, compact photonic models, and other information. The inputs required to create a PDK are experimental and simulation results and process and technology information. In turn, engineers use PDK to reliably simulate photonic integrated circuits and systems.

What is a Photonic PDK?

Photonic PDKs enable circuit and system level simulation, which is a critical part of the photonic integrated circuit (PIC) design process. The accuracy of simulation is contingent on the capability of the compact model library (CML) provided by the foundry as part of their process design kit. Foundry CMLs need to be calibrated against measurement data and capable of accurately modeling the behavior of the fabricated intrinsic photonic components and circuits. In this post, we describe steps to create a laser compact model using experimental results.

How does a Laser Impact Photonic Integrated Circuit’s Operation?

A crucial component that enables the operation of any PIC is the source of photons itself, the laser, as shown in figure 2, using a typical optical transceiver as an example.

Figure 2: Typical schematic of an optical transceiver. Lasers are used for light generation, different types of electro-optic modulators for light modulation, fiber couplers for coupling light into and out of fibers, fiber for light propagation, and photodetectors for conversion of light into electrical signals for further processing.

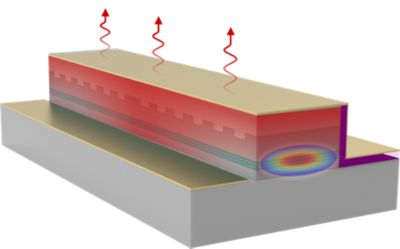

However, lasers can have a significant impact on the performance of photonic circuits because they introduce optical noise. Additionally, their noise and output power are strongly dependent on temperature. A typical structure of a PIC laser is shown in figure 3.

Figure 3: Typical structure of an edge emitting laser used as a light source in photonic integrated circuits. The optical mode is guided by the ridge waveguide and it is amplified as it propagates forward and backward in the optical cavity formed by the internal optical grating. Lasers are strong heat sources.

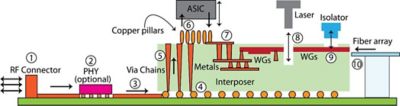

The packaging of photonic integrated circuits is a complex process that involves a lot of extrinsic pieces which can potentially degrade the overall performance of the circuit, as shown in figure 4. The temperature effects can be even more pronounced in co-packaged optics or electronic-photonic monolithic solutions, where the laser can be closer to other heat generating devices and its cooling may be more difficult. Analog Photonics and Ansys engineers teamed up to create a laser compact model with temperature effects and noise accurately considered. In this post, we describe the process of creating a laser compact model in Ansys Lumerical INTERCONNECT for the newest APSUNY Active Interposer (AI) Packaging PDK v.1.0.

Figure 4: Different electrical and optical packaging components in a photonic integrated circuit package using the APSUNY AI packaging process.

How to Choose and Setup a Laser Model in Ansys Lumerical INTERCONNECT?

Laser models range from simple lookup tables to more complex physical models. The lookup table models, such as CWL (Continuous Wave Laser), are easy to setup and are computationally fast, but they might not accurately model all the important laser effects. But, the more complex physical laser models, such as DML (Directly Modulated Laser) and TWLM (Travelling Wave Laser Model), require more parameters and longer computational time. Therefore, creating a laser model for a PDK requires choosing the best model to optimally satisfy often conflicting requirements between the number of known laser parameters, the model accuracy, and the computational time.

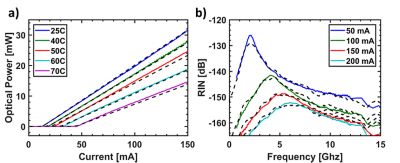

For developing APSUNY Active Interposer (AI) Packaging PDK v.1.0, Analog Photonics and Ansys engineers worked together to create a compact model of a proprietary laser device. Analog Photonics engineers measured the temperature-dependent lasing wavelength, light-current (LIV), and relative intensity noise (RIN) characteristics, which are critical performance metrics for direct detection data links. This was the full scope of parameters available about the laser. Given the fact that the number of known laser parameters was relatively small and the need to model the intensity noise accurately, DML was selected as the most optimal model in terms of trade-off between the input parameter complexity and model accuracy. The temperature dependent DML laser parameters were extracted by Analog Photonics engineers solely by fitting the model results to the LIV and RIN measurements at each temperature, without the need to know all the internal details of the proprietary laser device.

The comparison of the simulated and measured laser’s figures of merit is given in figure 5, showing a very good agreement.

Figure 5: A very good agreement between the light-current curve (a) and the relative intensity noise (b) of the measured and simulated lasers at different temperatures. Colored solid lines are measurement results and dashed black lines are from the Ansys INTERCONNECT DML model.

Conclusion and Additional Resources

The temperature dependence of the laser output power and the noise introduced by the laser can significantly affect the operation of photonic circuits. In this post we described the steps to create an optimal compact model for a proprietary laser device in Ansys Lumerical INTERCONNECT that takes the temperature effects and intensity noise accurately into account. This laser model is part of APSUNY Active Interposer (AI) Packaging PDK v.1.0.

For a more technically detailed version of this story and additional references, please check our related white paper: How to Create a Physics-Based Laser Compact Model for a Photonic Process Design Kit (PDK).