-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

June 13, 2022

Get the Best Digital Twin with Hybrid Analytics

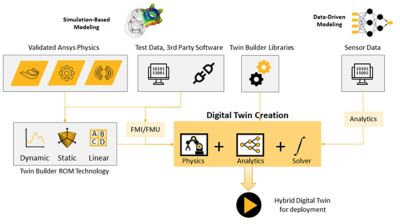

A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity, according to the Digital Twin Consortium. Today, with Ansys Twin Builder and artificial intelligence/machine learning (AI/ML) integration, engineers can blend data and physics to create an advanced digital twin: the hybrid digital twin.

Hybrid digital twins combine the power of physics and data modeling to enable real-time monitoring, predictive maintenance, and performance optimization, while supporting business value in numerous other ways. They also encourage collaboration across design and operations teams.

Hybrid digital twins bridge the gap between the design and operations process by merging design knowledge from simulation with field behavior from data. Conversely, a digital twin built on design specifications alone may reflect design intent while lacking field observation while a digital twin designed with field behavior in mind may lack design insight. Additionally, even if the original design incorporates field behavior, operating conditions in the field may change over time, including equipment degradation. As a result, a digital twin that provided high-fidelity representation of an asset or system when first deployed may deviate from the behavior seen in the field.

Hybrid digital twins provide a solution by automatically adapting and updating to these circumstances over time.

Hybrid digital twins help in four key areas:

- Reusing engineering design in operations

- Designing for data and learning from data

- Look-ahead performance

- Closing the design loop

Reusing Engineering Design in Operations

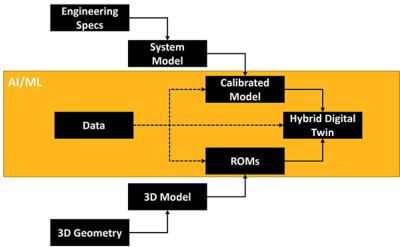

Hybrid digital twin solution architecture

Engineers often gain deep insights into how a system works through physical models built and simulated using high-fidelity finite element analysis (FEA) or computational fluid dynamics (CFD) solvers. Traditionally, these simulation models remain in the design phase as many models are not usable in operations because they are too computationally expensive.

Digital twins enable engineers to reuse high-fidelity design models in operations. Reduced-order models (ROM) are used to create lighter weight, faster running models that still preserve the fidelity of the physics in the design models.

In this way, a design model can be transferred over to a system model or digital twin, which also increases the scope of what a hybrid digital twin can be. Without ROMs, only simpler models could be used as a digital twin. ROMs enable more complex systems like furnaces and electrical machines to be modeled as digital twins.

Designing for Data and Learning from Data

Data and physics modeling working together provide better results than focusing on either of the two approaches individually. For example, machine learning models can track and predict valuable information, but only if they have been trained sufficiently. Missing sensor information can severely limit the usefulness of machine learning models. With this in mind, simulation-based twins can be designed to provide additional training data.

Hybrid digital twins use information that is available in the field to provide information that is not otherwise available. Still, a digital twin does require some information from physical sensors to fully connect it to the asset that it mirrors. Without this, there would be no way of knowing if the behavior matches or changes over time. However, once that match is established, the twin can provide additional information in the form of virtual sensors.

Physical sensors can be expensive, and some information is simply not obtainable by sensors, such as temperature throughout a furnace or an electromagnetic field at all locations in an electric machine. But a digital twin, based on underlying physics principles, can take physical sensor signals as input and calculate other physical quantities anywhere throughout the model. These calculations can be reported back as data that can be used by operators to better understand how a system works, or they can be used to train data models more robustly than physical sensors only.

Likewise, simulation models can learn from field data. By looking forward to operations, designers can parameterize a twin to learn from data and update itself in the field. A hybrid digital twin embodies a synergy between data and simulation where the simulation provides more data for data models while sensor data from the field teaches the model about operational performance.

There are two approaches when building a hybrid digital twin: top-down and bottom-up.

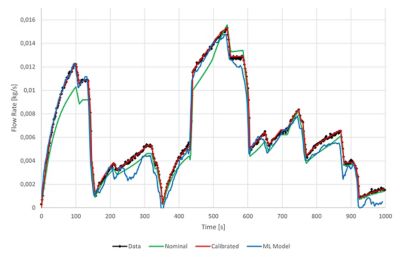

Look-Ahead Performance

Monitoring assets in the field is valuable but being able to predict future behavior is ultimately where digital twins provide maximum value. Hybrid digital twins are key for look-ahead performance prediction in unbounded conditions. Design teams prepare for what is anticipated, but unbounded conditions in the field often lead to unexpected situations. Data modeling alone will often fail in these situations because unanticipated scenarios by definition cannot have been included in model training. Physics models are needed to predict what is physically possible given some input conditions. Still, unless all of the physics is modeled, some predictions may be inaccurate. Sensor data is needed to inform the twin when its predictions are falling short. Therefore, calibrating a twin with current sensor data provides confidence that future physical predictions are accurate.

With these two ingredients, twins can be used to predict future behavior based on current conditions or to search for a better outcome by optimizing process inputs. An operator may see that a process is not performing in a way that yields the expected quality. The operator can use the twin to test different controls to see what will bring the process back within constraints. The operator can then intervene to adjust the process controls. This capability is even more relevant in dynamic processes in which history matters and uncertainty propagation jeopardizes the accuracy of future state predictions. In other words, optimizing a twin for best performance now has ripple effects for future performance. A good example of this is optimizing a drilling process where the next drilled feet are intimately related to the history of the wellbore.

Comparison of the final results for a flow network, for a data-only model, a simulation-only model, and a hybrid model.

Closing the Design Loop

As we have discussed, a hybrid digital twin can adjust to field behavior to provide better predictions and match physical behavior to enhance operations. However, while this is invaluable, it is incomplete if the acquired information remains only in the field. Alternatively, learnings captured in the field can and should feed back information to design teams to improve the next iterations of design and control.

Once a twin is learning an asset’s behavior, it can be used to perform what-if scenarios to see how the asset would behave with different sizing and operating conditions, or a combination of the two. This can be achieved either by taking the twin offline temporarily to run analysis or by launching a separate copy of the twin to investigate what-if scenarios while the original twin continues to monitor the equipment.

In the case of degradation or equipment failure, a twin can help diagnose weak points in the design. By continuously learning from field data, an updatable twin shows which components and parameters are changing over time. This information can be used to predict the remaining useful life of a piece of equipment. Tracking this is valuable for predictive maintenance, but also for design teams to see whether equipment is performing as expected. And if it isn’t, the designers know what aspects of the equipment to focus on.

Beyond looking at a single asset or design, copies of the same digital twin deployed in a fleet give accumulated statistical information. Consider vehicles for example. Vehicles operating in harsher conditions will likely have different feedback than other parts of the fleet. The information over time gives operators information about the limitations of the current design in the field, which helps designers extend and enhance future vehicle designs. Additionally, operations observations provide real statistical estimates of safety margins and tolerances.

Take a Closer Look

We have highlighted a few ways in which hybrid digital twins bridge the gap between design and operations to close the design loop and provide better value from digital twins, but the list is certainly not exhaustive. Once the tools and pieces are in place to use both simulation and data, the ingenuity of design and operations teams will create unique solutions specific to each use case in addition to the general benefits we have outlined.

We have focused here on the benefits of combining data and physics modeling into a hybrid digital twin. For more information, watch our webinar Get the Best Digital Twin with Hybrid Analytics or review the IEEE paper, “Hybrid Digital Twins: A Primer on Combining Physics Based and Data Analytics Approaches,” for additional techniques of combining data and physics modeling.

In the near future, we will highlight additional methods for fusing data and physics modeling more tightly into a unified workflow, something we refer to as fusion modeling. To stay informed, follow the Ansys blog for future articles.