-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

January 11, 2024

Survey of French Companies Shows the Impact of Simulation on Sustainability

Because global climate change can be traced, in part, to greenhouse gases being emitted by products and processes that are part of our daily lives, it is up to us to develop sustainable solutions to reduce the world’s carbon footprint to safer levels, as specified by the Paris Accords. At the same time, the pace of business is requiring developers to deliver new products to market faster and at lower cost. This acceleration to market would seem to be at odds with the careful steps needed to ensure that new products are sustainable.

Fortunately, Ansys engineering simulation software can help engineers develop sustainable products at the necessary pace by enabling them to virtually build and test hundreds of digital prototypes on a computer in the same time that it once took to build and test one physical prototype. Adding high-performance computing (HPC) and digital twins into the mix can further accelerate development times and make it easy to monitor the operation of the product to ensure a high level of energy efficiency in real time.

But these benefits accrue only if engineers across industries are aware of and are taking advantage of simulation software, HPC, and digital twins. To gauge the level of adoption of these technologies, Ansys engaged Infopro Digital to survey 300 companies in France about their product development practices. Here we present some of the key findings of this study.

Commitment to the Environment

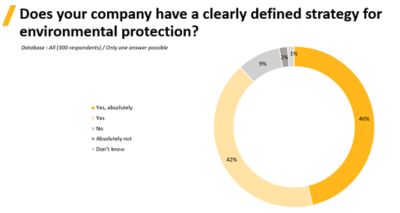

The survey found that 88% of the 300 companies have a clearly defined strategy for environmental protection. Seventy-seven percent said that the environmental impact of their products is a priority for their company. These numbers are very encouraging while still leaving room for improvement.

One of the ways respondents are addressing environmental concerns is through material data management through the life cycle of their products. The survey found that:

- 40% of companies definitely consider the possibility of recycling or upcycling when choosing materials for their products.

- Another 45% said they probably take recycling or upcycling into account.

- 82% perform material sustainability studies for their products.

So, sustainability is clearly a priority for these companies. But 58% of respondents said that they have trouble finding reliable material property information for use in designing their products. They could help overcome this problem by using Ansys Granta MI, an intelligent materials database with over 700 materials and their properties available for ready use in computer-aided design (CAD) and simulation software. Granta MI also provides a single source of truth for material properties across the company, so all engineers can access the same materials data. And it allows you to add the properties of proprietary materials you may have developed in-house to the database.

Awareness and Use of Simulation, HPC, and Digital Twins

The majority of respondents are aware of digital simulation, HPC, and digital twins, with many using them. However, more than a third were unaware of digital twin technology (38%) and HPC (36%), as shown in the table below.

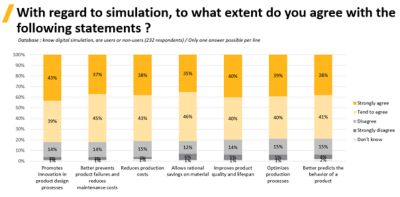

Clearly, this suggests large opportunities for companies to expand their use of simulation, HPC, and digital twins to improve the digital footprint of their products and processes. A vast majority of respondents, including simulation users and non-users, see the value in engineering simulation:

- 82% recognize that simulation promotes innovation in the product design process.

- 82% say that it better prevents product failures and reduces maintenance costs.

- 81% believe that it reduces production costs.

- 81% say that it allows rational savings on materials.

- 80% agree that simulation improves a product’s quality and lifespan.

- 79% say that it optimizes production processes.

- 79% say that it better predicts the behavior of a product.

Regarding HPC and digital twins, Ansys solutions that could help these companies include:

- Ansys HPC software uses today’s multicore computers to perform more simulations in less time. These simulations can be bigger, more complex, and more accurate than ever using HPC. The various Ansys HPC licensing options let you scale to whatever computational level of simulation you require, from single user or small user group options for entry-level parallel processing up to virtually unlimited parallel capacity.

- Ansys Twin Builder enables you to implement complete virtual prototypes of real-world systems. These can be deployed to manage the entire life cycle of products and assets. This digital twin simulation paradigm allows you to exponentially increase efficiencies over time, scheduling maintenance around predictive methodologies that become more accurate with real-world testing and response. Access to this information allows engineers to unlock additional value from existing assets, which prevents unscheduled downtime and lowers operating costs, while working at optimal efficiency, and all with agnostic Internet of Things (IoT) platforms.

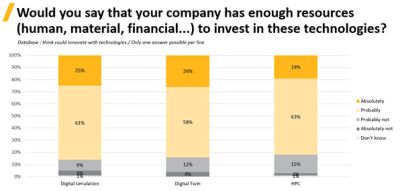

The majority of respondents whose companies could potentially use these technologies think that they have sufficient means to invest in them.

Future Prospects for Innovation

Hydrogen and nuclear power are two of the alternative energy technologies that the survey specifically inquired about.

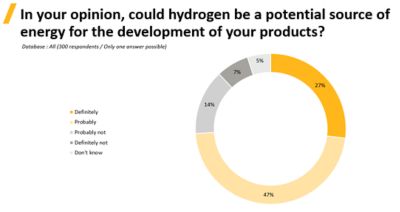

Seventy percent of respondents believe that hydrogen will be adopted as an energy source in the future. When asked “In your opinion, could hydrogen be a potential source of energy for the development of your products?”, 74% of respondents said “definitely” or “probably.”

Of these companies, 82% said their company has all the tools needed to deploy this energy vector.

Regarding nuclear power, 74% said they can envisage the achievement of carbon neutrality using nuclear power.

Regardless of the technology — be it wind, solar, sustainable aviation fuels, geothermal, nuclear, hydrogen, biofuels, batteries, carbon capture, or others — French companies for the most part recognize the value that engineering simulation brings to their product and process design efforts. For those not currently aware of simulation, HPC, and digital twin technologies, now is a great time to educate them about the benefits they are missing. It is essential that we all use the best tools available to reduce greenhouse gas emissions and mitigate global climate change for the benefit of the planet.

Learn more about how Simulation 4.0 leads the path to sustainable development in the "Simulation 4.0 and the Industrial Transition – The Path to Sustainable Development" webinar which covers:

- The challenges of industrial transition in the context of sustainable development.

- The role played by engineering simulation and other state of the art technologies such as HPC and digital twins.

- Future challenges for manufacturing industries.

Download the full Sustainability and Engineering Simulation survey report.