-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

February 19, 2021

Design and Maintain Turbomachinery Using Ansys Simulation Solutions

Whether you are developing fans, pumps, compressors or turbines, Ansys simulation software allows you to quickly iterate and improve on designs. Simulation provides insight to key metrics prior to manufacturing and testing. It is a reliable method to increase efficiency while reducing development costs and time to market.

Ansys simulation software is extensively validated across multiple industries and applications. These simulation tools provide accurate and reliable data that drastically reduce manufacturing costs and test time. Additionally, Ansys simulation software is built with an emphasis on streamlined, intuitive workflows that give engineers more time to focus on critical design decisions. The fact that Ansys flagship products are agnostic to computer-aided design (CAD) and blade design tools provides utmost flexibility for designers to use any blade design tools from Ansys' partners.

Comprehensive Multiphysics Solutions in One Portfolio

As we look at the whole machine solution, simulation capabilities include fluids, thermomechanical, structural and, of course, multiphysics solutions that leverage Ansys flagship products such as Ansys Fluent, Ansys CFX, Ansys Mechanical, Ansys FENSAP-ICE and Ansys LS-DYNA. As you begin to simulate and analyze these multiphysics applications, you need to ensure accurate and efficient data transfer between the solvers. Our platform allows all Ansys solvers to accurately and efficiently transfer and map data, which results in the most robust and accurate multiphysics simulations for aeromechanics, fluid–structure interaction, conjugate heat transfer modeling, foreign object damage assessment and blade-out (burst) analysis.

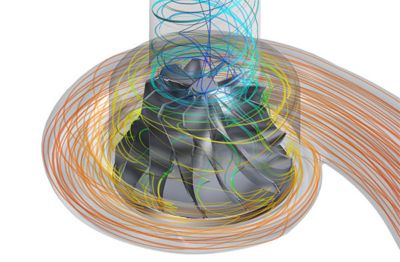

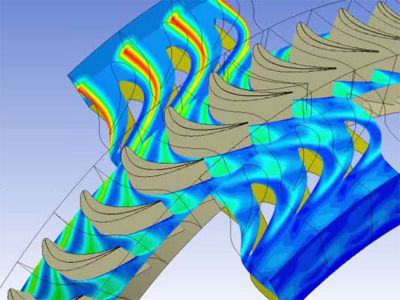

In the design of gas turbines and turbomachines, Ansys provides organic aeromechanic solutions to predict blade flutter, forced response, vibro-acoustics and mistuning leveraging CFX, Fluent and Mechanical. The coupling between fluids and structures using cyclic symmetric models and mode superposition allows enormous speed-up. A streamlined aeromechanics workflow between computational fluid dynamics (CFD) and finite element analysis (FEA) with hot-to-cold mapping reduces design cycle time and enhances analysts' productivity by enabling them to focus on the best ways to prevent machine resonance and avoid non-synchronous high cycle fatigue.

Flutter simulation of a fan blade using fast harmonic balance method.

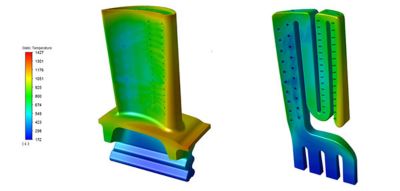

Desire for higher engine efficiency is driving the turbine inlet temperature higher than the material's melting point. Trade-offs between aerodynamics, heat transfer, stress and materials are necessary for optimal design and to avoid failures caused by thermomechanical fatigue, stress rupture or oxidation. To verify material and thermal barrier coating integrity and to assess hot section components' durability, designers leverage Ansys tools to perform steady and transient conjugate heat transfer (CHT) simulations. Ansys Fluent and Ansys CFX build on a parallelized and user-friendly meshing platform to provide fast solution methods that make CHT analysis practical in any production environment. Therefore, simulations of blade and vane conjugate heat transfer with internal passages have become routine. Designers can also apply blade film cooling modeling techniques at the concept and detailed design phases with seamless mapping of the 1D network of cooling flows

Film cooling modeling of a cooled turbine blade.

A powerful solution in Ansys’ multiphysics portfolio is the ability to predict and prevent engine failure scenarios due to foreign object damage or blade out. LS-DYNA equips designers with the ability to predict bird strike and blade out damage and their impacts on engine performance in accordance with regulatory requirements. Fan blade out and bird ingestion events are modeled using Ansys explicit dynamics solutions. They consist of multiphysics simulation that leverage several analysis approaches (Lagrangian Finite Elements, Arbitrary Lagrangian Eulerian, Smooth Particle Hydrodynamics). LS-DYNA also supports turbine blade out and disk containment simulations. These solutions support recognized blade out and bird strike certification requirements.

Fan blade out containment simulation in LS-DYNA.

Simulation of bird strike on a fan using LS-DYNA.

Advanced Physics to Design the Next Generation of Turbomachines

To realize designs that meet performance and regulatory requirements over a wide range of operating conditions, Ansys provides unique capabilities to tackle the most advanced physics. Ansys equips designers with tools to accurately predict complex physics such as pump cavitation, fan/compressor icing, combustor–turbine interaction and the acoustics behind fan noise.

The icing solution with Ansys FENSAP-ICE allows for the prediction of ice accretion and shedding for long intervals on static and rotating components. FENSAP-ICE allows you to assess imbalances and possible damages due to ice shedding in a streamlined workflow for turbomachinery applications. The solution supports recognized icing certification envelopes for aircraft engines (standard droplets, supercooled large droplets and high-altitude ice crystals).

Prediction of ice-accretion and shedding using Ansys FENSAP-ICE.

Understanding the operating range of the pump where cavitation begins is critical. High-fidelity cavitation models in CFX and Fluent, such as Rayleigh-Plesset in combination with advanced multiphase and turbulence models enable turbomachinery manufacturers to accurately predict the pump operating limits beyond which cavitation occurs and becomes substantial.

Simulation of a gerotor pump showing the extent of cavitation (red) on the gear wall.

In the context of designing long-life gas turbine blades and vanes with optimized cooling patterns, Ansys makes it possible to accurately predict hot-streak migration through the high-pressure turbine (HPT) stages. Designers can model joint and/or co-simulation of the combustor and the HPT. Combustor–turbine vane modeling with conjugate heat transfer is performed in a single simulation for accurate hot-streak tracking using high-fidelity scale-resolving turbulence models. This leads to accurate thermal management of blades and vanes, and significant improvement of turbine durability.

Ansys CFX and Fluent solvers have capabilities for aero-acoustics ranging from fast and simple broadband noise source modeling to the most comprehensive computational aero acoustics (CAA) using advanced scale-resolving turbulence models.

Computational aero-acoustic analysis of an industrial fan.

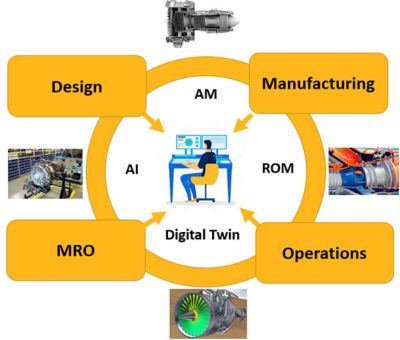

A Streamlined and Automated Simulation Process in the Product Life Cycle

Ansys is pervasive in the design process, and now Ansys simulation extends into manufacturing, operations, and MRO (maintenance, repair and overhaul), making simulation pervasive throughout the product lifecycle with feedback into the design process. Leveraging additive manufacturing helps push the boundaries of conventional designs and unlocks tremendous possibilities in design for manufacturability.

Moreover, building reduced-order models (ROMs) to create digital twins enables predictive maintenance and helps improve the performance and reliability of turbomachines. The same information can be leveraged to build machine learning algorithms and use artificial intelligence to infuse the knowledge and expertise into the design process. Ansys provides cutting-edge tools in this continuous loop that make valuable data and expertise available to design engineers who, in turn, can make timely and judicious decisions to improve machine life , efficiency and overall system performance and reliability.

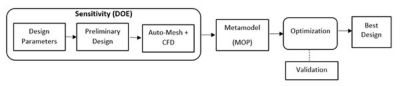

Turbomachinery designers are constantly challenged to identify the most influential design variables and to build robust designs that fit all physics requirements while minimizing the number of defects and manufacturing constraints. Ansys optiSLang unlocks the power to achieve robust designs with high-performance algorithms using sensitivity analysis, optimization and robustness evaluation. It automates the identification of the best metamodel to represent performance variation with design variables. This is achieved in an environment where process integration, automation of chained data flows, design space exploration and uncertainty quantification are ubiquitous. The schematic below shows the process integration and design optimization workflow for a centrifugal compressor that substantially increased engineering productivity and machine performance while reducing design cycle time from more than a year down to couple of weeks.

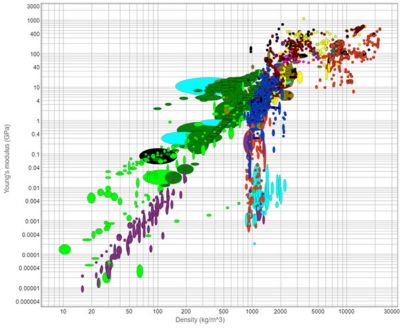

Turbomachinery designers need to base many decisions on materials and their properties. Ansys Granta provides an efficient way to select, share and manage materials data across the organization. It can characterize complex material properties, index all test data and provide a single secure source of certified materials information available to all engineers and analysts throughout the product life cycle. Ansys Granta can also manage legislated substances in bill of materials (BoMs).

Ansys Additive’s comprehensive solution spans the entire workflow — from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials. DfAM includes topology optimization, which enables lightweighting of oversized parts. These lightweighted parts can be virtually tested for the real-world conditions they will experience to assess their structural integrity. Ansys Additive Print helps build physics- or geometry-based supports. Additive process simulation can predict part shape, distortion and stresses to get the print part right the first time.

Radial impeller print process simulation using Ansys Additive solution.

MRO spending on turbomachinery is significant and, in many cases, much higher than the original machine purchase price. Hence, the ability to predict when maintenance is needed provides significant advantages to OEMs and their customers. Ansys has a range of ROM capabilities that can be effectively used for predictive maintenance. The image below highlights how Lufthansa Technik uses flight data and simulations to build field ROMs that can predict failures of critical gas turbine engine components. The simulation workflow in this case included aero-thermal analysis using CFX and Mechanical. Statistics on Structures (SoS) technology in Ansys optiSLang is used to perform sensitivity studies on selective flight data to build field metamodels. These field ROMs accurately predict temperatures, stresses and strains in real time, enabling evaluation of the remaining life of critical engine components.