-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

December 8, 2023

Complete Your Digital Thread with PLM, SPDM, and Material Intelligence

As digital transformation continues to impact nearly every industry around the world, product development companies are faced with the challenge of keeping track of an ever-expanding mountain of digital information. For decades, companies have relied on product life cycle management (PLM) systems to track and manage computer-aided design (CAD) data. But as companies rely more heavily on simulation technology as an integral part of the product development process, they are finding it difficult to track and manage the data that is produced by simulation. This is where simulation process and data management (SPDM) can help.

Contrary to popular belief and despite their similarities, SPDM and PLM are not the same thing. PLM systems have been developed over the years to manage CAD data and their capabilities are optimized to deal with the specific requirements of how CAD files need to be organized and controlled. Simulation data is very different from CAD data, so a different set of capabilities are required to manage it effectively. While PLM is geared for design engineers, SPDM is designed to meet somewhat different requirements of simulation analysts and engineers. Many PLM companies have developed add-on modules to their PLM systems to address the needs of simulation analysts, but despite their best efforts, PLM systems are not as well suited to the task as SPDM systems that have been specifically designed from the ground up to deal with simulation data and processes.

While it’s natural for companies to assume that their existing PLM system can be expanded to accommodate simulation data, in practice, this is very inefficient. It is a better approach to extend the value of PLM by adding an SPDM system that is optimized to handle the unique requirements of simulation engineers and the data they generate. The Ansys Minerva SPDM solution seamlessly integrates with existing PLM systems. Not only does this allow companies to keep and enhance their established workflows, but the Ansys SPDM solution helps create a complete digital thread of simulation files, material intelligence, PLM data, and more by offering interoperability with a wide range of tools. By integrating your PLM solution with Minerva, you can manage more complex workflows, track work in process throughout your organization, and increase sustainability.

Create a Complete Digital Thread

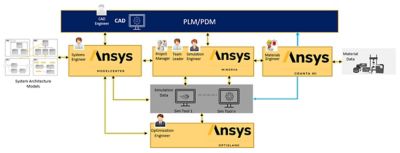

Minerva is part of the Ansys Connect family of products, which includes Ansys Granta MI Enterprise materials management, Ansys optiSLang process integration and design optimization, and Ansys ModelCenter model-based systems engineering (MBSE) software. More importantly, Ansys Connect products seamlessly integrate with each other and therefore connect easily to existing PLM systems by way of Minerva. With sustainability concerns increasing globally, material intelligence in particular is a great asset to any company.

Ansys Connect products empower organizations to create a complete digital thread.

Material intelligence contributes significantly to operational sustainability internally and externally. With insight into material properties — including physical, chemical, or mechanical components, and details about the toxicity, carbon footprint, and recyclability of such components — organizations can select cleaner materials. By choosing better materials, organizations can align with corporate sustainability goals and reduce the environmental impact of their products. Further, by integrating this data into a digital thread the benefits of material intelligence are magnified, providing critical insight to inform design and development from the earliest stages of conceptualization through to the final stages of production.

With its vendor-neutral architecture, Minerva blends easily into existing PLM workflows and integrates with Granta. This means that companies do not need to move their design data out of their PLM system into Minerva or Granta. Minerva simply weaves a digital thread, connecting simulation data, material intelligence, and related files to the CAD or design data in the existing PLM system. A digital thread helps teams monitor projects from start to finish, providing traceability, connectivity, and improved collaboration across departments throughout an organization.

Ansys Minerva blends easily into existing product life cycle management (PLM) workflows and integrates with other Ansys Connect products to create a comprehensive digital thread.

Sure, traceability enables you to track and monitor data throughout the product life cycle but it’s more than just that. Minerva’s traceability capabilities, integration with Granta, and interoperability with existing PLM systems enable you to locate correct versions of files and make universal changes more easily and accurately from different points of development.

For example, suppose you created a CAD model, which satisfies the technical requirements and specifications for whatever you intend to build. If your engineers need to change those requirements or material for an environmental concern, you need to change your CAD model. But which version of the model do you need to change? And what new material data do you need to incorporate? A digital thread — complete with simulation, material, and PLM data — eliminates any guesswork and drastically minimizes the manual back-and-forth effort required between teams to communicate information, locate correct model versions, and address design changes. So, more than just traceability, a complete digital thread offers accurate traceability.

Leverage Unique Expertise to Enhance PLM and SPDM

It’s important to note that some PLM systems offer add-on modules to manage simulation data. However, this isn’t an ideal solution. Why? Because your PLM system isn’t designed for simulation data, it isn’t optimized for managing or processing it, and it won’t work as successfully as it could or should. Basically, it’s like placing an appendage onto an existing system and trying to make it do something that it wasn’t designed to do. As a result, it doesn’t do it well.

Let’s consider another popular system used by product development companies. Companies generally use enterprise resource planning (ERP) systems to manage manufacturing data, including inventory, orders, and accounting. Usually, the business side of a product development company happens in the ERP system, while the design engineering side happens in the PLM system. In the same way a company would never consider running ERP processes in a PLM system, companies shouldn’t try to run simulation processes in a PLM system. It’s not built for it. Minerva is optimized for simulation and SPDM, PLM is optimized for CAD processing and data management, and ERP is optimized for manufacturing process management.

Take a Comprehensive Approach to PLM

Many companies are trying to create a digital thread, and some think they have accomplished it. However, if companies are not including simulation data into their digital thread, then how is that digital thread complete? It’s not. Alternatively, companies can integrate simulation and materials data into their digital threads to establish a more complete line of connectivity across all areas of their workflow.

Similarly, companies that rely on PLM systems alone to manage simulation data are not taking a comprehensive approach to PLM. An SPDM solution working in tandem with PLM cultivates a fuller, all-encompassing digital thread and improves even more by integrating additional insight like material intelligence.

To learn more about how an SPDM solution can benefit your team, request a free assessment for Minerva. To discover more ways that a material solution can improve your operations, request a free assessment for Granta.