-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

April 12, 2022

BMW Drives Toward a Sustainable Future

While the automotive industry has been focused on developing innovative electric vehicle (EV) designs for years, there is a new sense of urgency today. Worldwide sales of EVs are increasing quickly1, growing by 46% in 2020 and by 160% in the first half of 2021.

Consumer demand is an important factor, but equally important are government mandates. In 2021, the European Union introduced stricter CO2 emissions guidelines for the automotive industry, while China mandates that EVs must make up 40% of all automotive sales by 2030. U.S. President Joe Biden has announced an extremely ambitious goal: by 2030, EVs should represent 50% of the country’s new car sales, up from just 2.5% in 2021.

Meeting these targets means automotive development teams need to overcome some tough engineering challenges, including more cost-effective battery designs, more efficient powertrains, and more robust electronics architecture. By investing in innovation, BMW has positioned itself at the forefront of this drive toward sustainability, with 15 EV models in production2 and a goal of having EVs represent 50% of all worldwide sales by 2030.

BWM Group has been leveraging Ansys software for years to solve diverse EV engineering challenges. In 2020, BMW’s Department of Power Electronics, based in Munich, began applying Ansys Sherlock to help predict the life of critical EV semiconductor components — including the power systems that underlie on-board chargers (OBCs) and DC-DC converters, which supply the desired voltage and current needed to charge the battery. These power systems are part of a much larger and complex electronics architecture that must perform reliably under every foreseeable driving and charging condition.

“The importance of electronics is continuously increasing in the automotive industry,” says Dr. Pascal Schirmer, development engineer for the Department of Power Electronics at BMW Group. “The usage of simulation tools from Ansys, such as Ansys Sherlock, allows us to optimize in a very early design phase the performance and reliability of the electronic components, while managing for the growing complexity.”

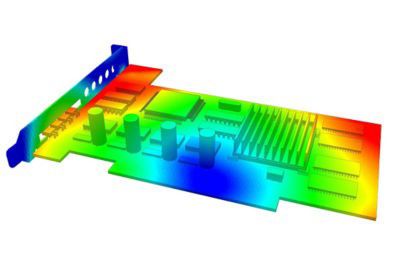

According to Schirmer, printed circuit boards (PCBs) are an increasing focus as automotive engineering teams work to make their EV designs more efficient, powerful, and reliable. “Printed circuit boards must include more functionality as power demands increase,” he notes. “But at the same time, they must be lighter and smaller, to reduce overall vehicle weight and size. This results in some sophisticated engineering trade-offs.

“For example, a smaller package size makes it harder to distribute power loss across the board, and it also creates a greater risk of thermal build-up due to increased circuit density,” he continues. “Sherlock helps us investigate these kinds of trade-offs at a very early design stage, before significant development costs have been invested.”

Download our whitepaper to learn more about Automotive Electronics Reliability.

The Sherlock Advantage: Fast, Thorough, Early-Stage Analysis

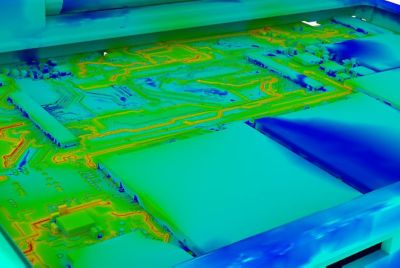

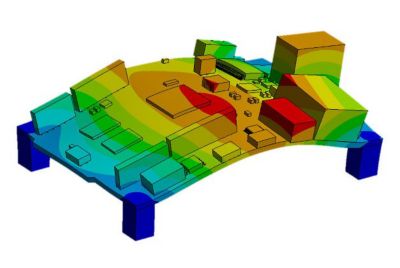

As the industry’s only physics-based electronics reliability assessment tool, Sherlock enables Schirmer and his team at BMW to assess the performance of PCBs under a range of thermal cycles, including temperature changes and static temperatures. BMW can also test PCB components for shock, random vibration, and steady mechanical loads. Sherlock is purpose-built to make fast, accurate life predictions at the component, board, and system levels.

“The four biggest failure modes for automotive electronics are thermal stress, mechanical stress, humidity, and dust,” explains Schirmer. “Seventy percent of failures arise from one of these causes. Ansys has the unique capability to model all of these.”

Sherlock’s embedded libraries, composed of more than 200,000 distinct parts, enable BMW to quickly and easily convert electronic computer-aided design (ECAD) files into computational fluid dynamics (CFD) and finite element analysis (FEA) models. “Generating parts lists by leveraging the pre-existing Ansys library, based on the electronic bill of materials, is extremely helpful in efficiently generating models and calculating reliability results,” notes Schirmer. Each Sherlock-generated model contains accurate geometries and material properties, supporting the rapid translation of stress information into validated time-to-failure predictions.

Designed for fast, early-stage electronics analysis, Sherlock bypasses the traditional and time-consuming process of “test, fail, fix, repeat.” Schirmer and his team can accurately model and re-model silicon–metal layers, semiconductor packaging, PCBs and assemblies well before the physical prototyping stage. They can adjust their designs to account for power loss, high thermal loads, and other failure modes, as well as testing new materials or package sizes.

“The iterative generation of models during the experimental phase was both time- and labor- intensive, especially when it came to updating the models,” Schirmer points out. “The ability to update the ODB++ data, as well as the parts list, using the internal Ansys database enables an efficient and easily manageable update between each sample phase.”

Improved Innovation — and a 3x Acceleration in Analysis

Given the growing demand for new EV designs and product features, the Department of Power Electronics is under pressure to complete its reliability studies quickly — but without compromising analytic depth and breadth. “With Ansys Sherlock, I’m able to manage 90 to 95% of my analytic modeling with a single tool that integrates easily with Ansys Workbench, Ansys physics-based solvers, and ECAD tools,” says Schirmer. “I’m grateful to have a partner who understands my needs and responds to them with the right capabilities.”

Schirmer notes that Sherlock has delivered up to a 3x acceleration in BMW’s reliability testing for electronics components like OBCs and DC-DC converters. “Of course, saving time allows us to get designs launched faster,” says Schirmer, “but it also supports innovation. I can look at a wider range of charging scenarios, in greater depth. I can do more experiments. I can make discoveries. That adds up to product innovation, which is absolutely critical at BMW in meeting our goals for electric vehicle adoption and sustainability.”

Ready to see Sherlock in action? Request your free software trial today.

Resources

- “How Electric Vehicles Offered Hope as Climate Challenges Grew,” ScienceNews, Dec. 22, 2021

- “Transformation and Responsibility: BMW Group Steps up Technological Change for Sustainable Future,” BMW press release, March 16, 2022